Does aluminum alloy auto parts die casting have sufficient strength and toughness?

20-05-2025Strength basis of the material itself

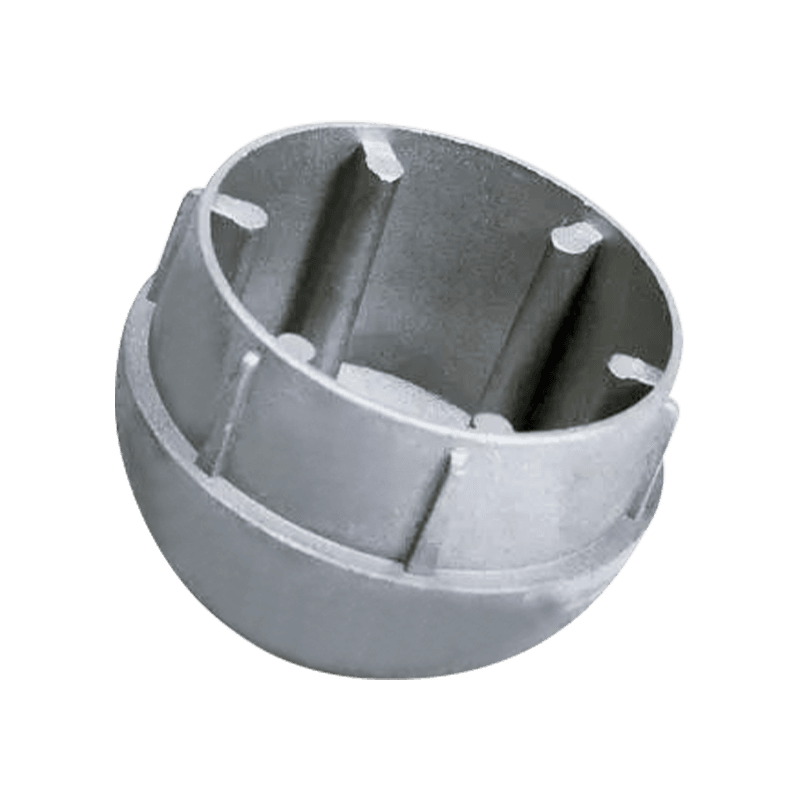

The aluminum alloy materials used for die-casting of automotive parts are mostly silicon-containing aluminum alloys, such as ADC12, A356, etc. This type of alloy has both high strength and moderate ductility. Its organizational structure can show good mechanical properties after reasonable smelting, forming and heat treatment. Without increasing the weight, the compression and tensile resistance of aluminum alloy die-castings at the stress-bearing parts can usually meet the design requirements of the automotive industry.

The impact of process control on performance

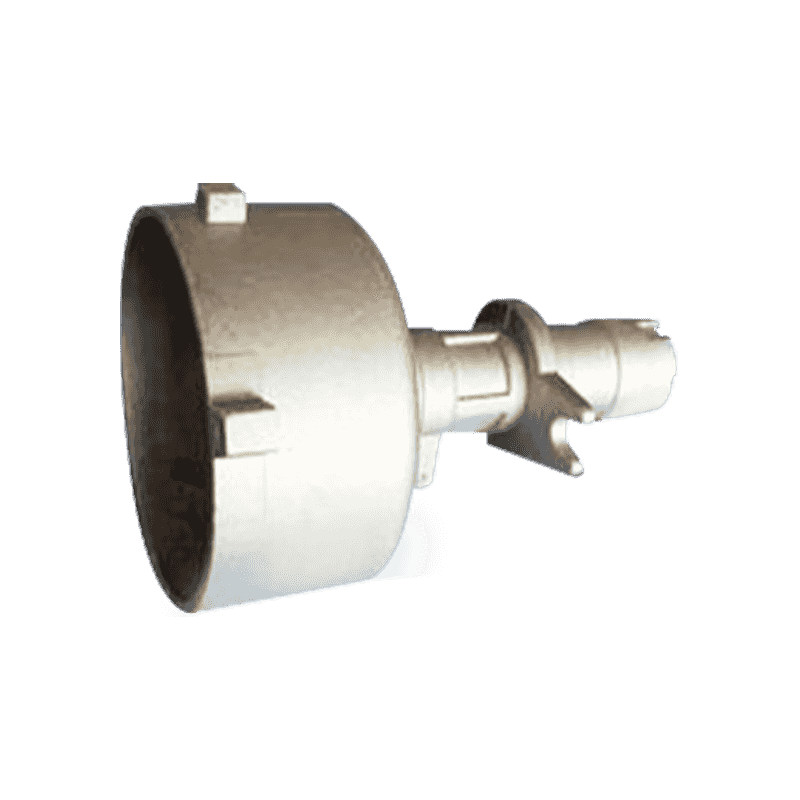

In the process of aluminum alloy die-casting, process control directly determines the strength and toughness level of the finished product. If there are problems such as internal pores, shrinkage or slag inclusions in the die-casting, its strength will be significantly reduced. In modern die-casting technology, vacuum die-casting and semi-solid die-casting are widely used to reduce the probability of defects and improve organizational density. Through reasonable mold design, alloy temperature control, and pouring speed adjustment, the mechanical properties of parts can be effectively guaranteed at the process level.

Heat treatment improves performance

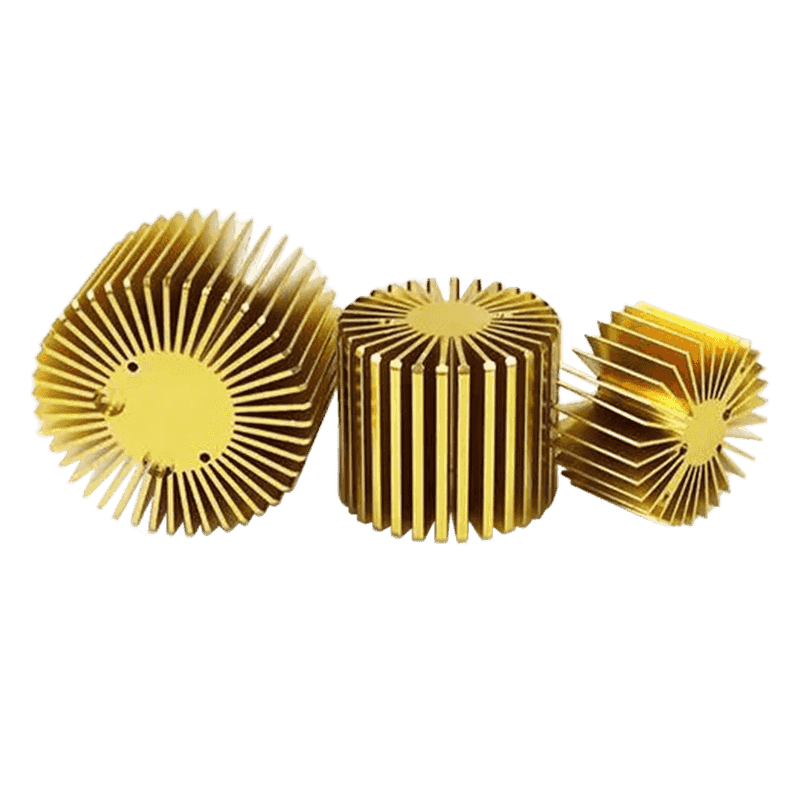

Some aluminum alloy die-castings can improve strength and toughness through heat treatment, such as T6 heat treatment process. This process refines the alloy grains, makes the structure uniform, and enhances the overall mechanical properties by dissolving strengthening elements and performing aging treatment. However, not all die castings are suitable for heat treatment, so material selection needs to be closely coordinated with subsequent process links to maximize performance.

Actual performance in use scenarios

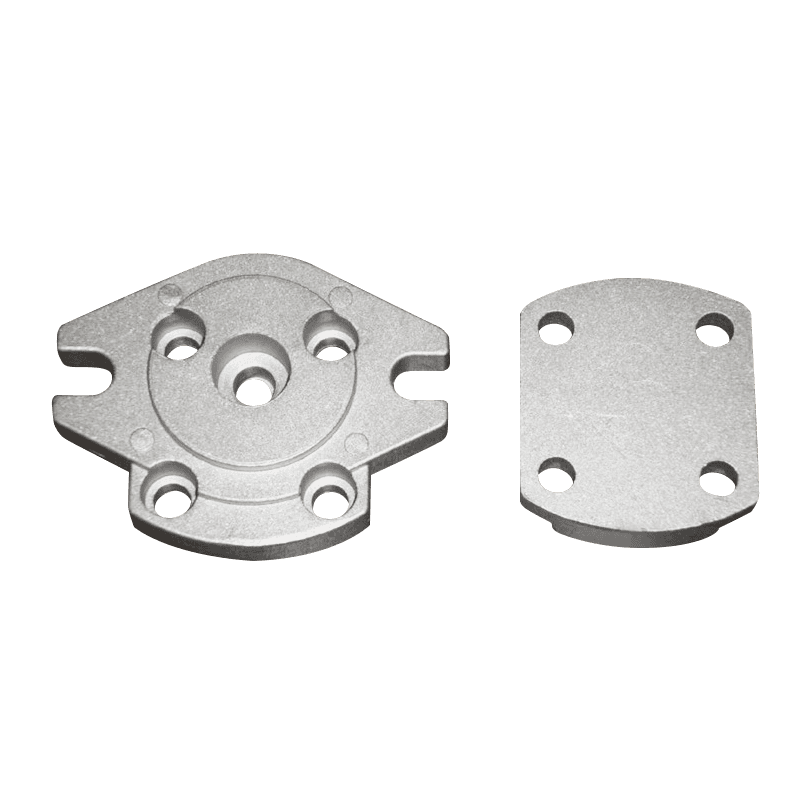

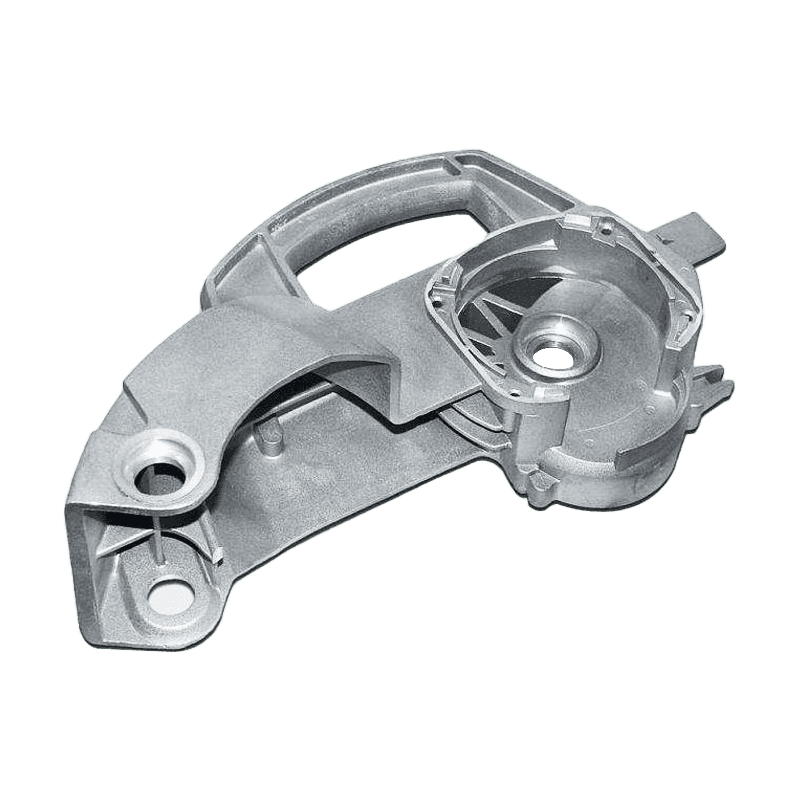

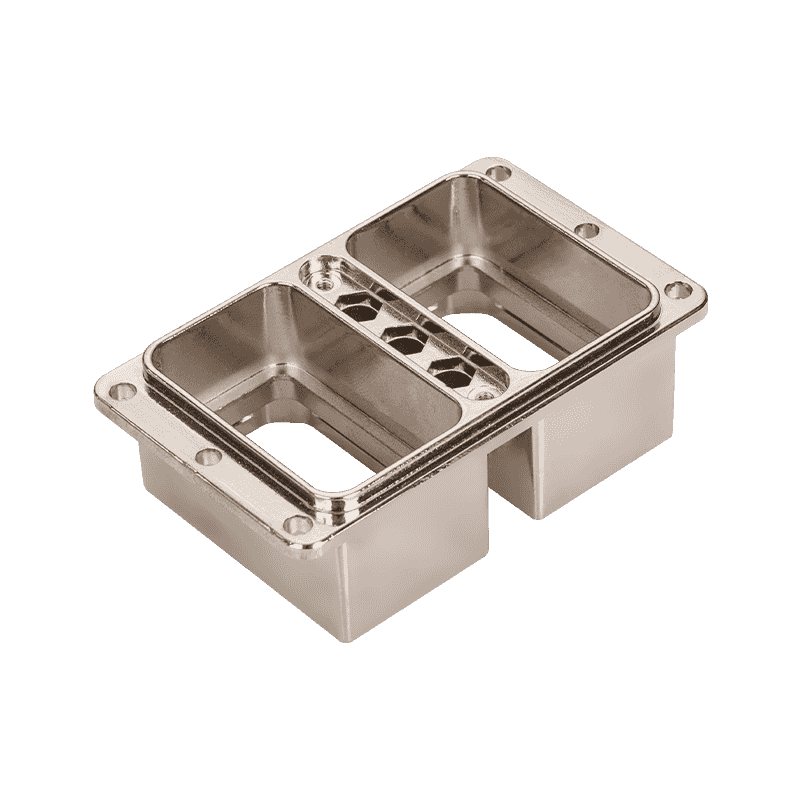

In actual applications, aluminum alloy die-casting parts are usually used in locations that do not directly bear severe impact but require a certain structural strength. For example, in suspension brackets, die-castings need to withstand vibration and dynamic loads for a long time, and their strength and toughness must meet the corresponding standards. Many actual test cases show that aluminum alloy die-castings produced through standard manufacturing processes can work stably in these parts and maintain structural reliability during the service life.

Comprehensive consideration of safety and durability

Although aluminum alloys are slightly lower in hardness than steel, after precise design and scientific manufacturing, their strength and toughness can meet the use requirements of most automotive parts. In addition, aluminum alloys are naturally resistant to corrosion and show stability in long-term use. This balance of comprehensive performance makes its application in automotive structural parts more attractive.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский