Can aluminum alloy auto parts die casting replace traditional steel parts to reduce the weight of the vehicle?

27-05-2025Material density comparison and actual effect

The density of aluminum alloy is much lower than that of steel. Under the same volume, the weight of aluminum alloy parts is much lighter. Therefore, using aluminum alloy instead of steel in the automobile structure can theoretically effectively reduce the weight of the whole vehicle. However, this transformation cannot simply rely on the difference in material specific gravity, but also needs to consider the matching of structural design and strength requirements. Through reasonable design, aluminum alloy die castings can not only achieve the goal of weight reduction, but also maintain structural stability.

Process advantages of aluminum alloy die casting

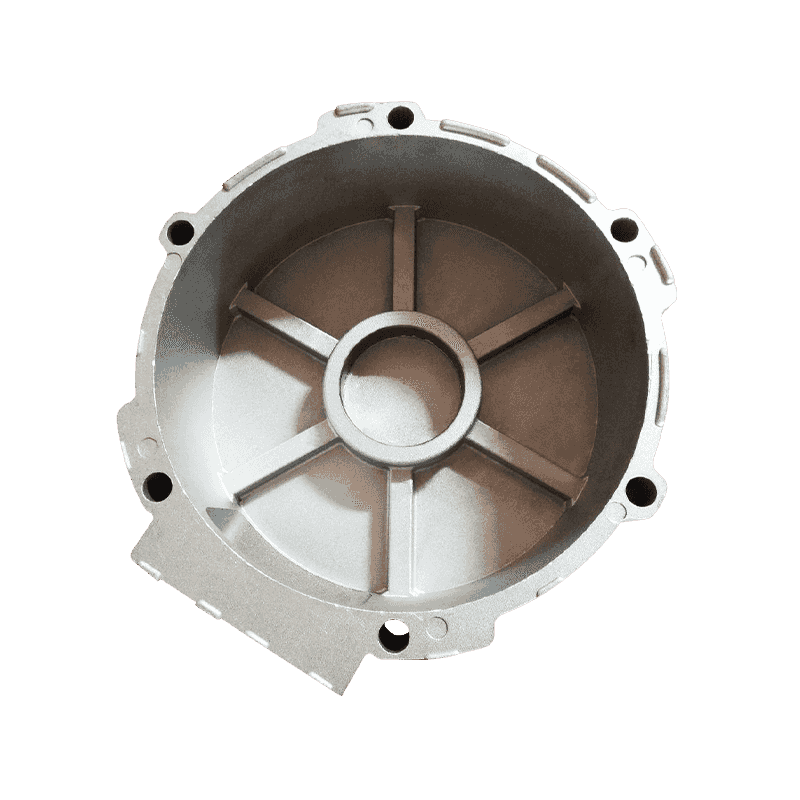

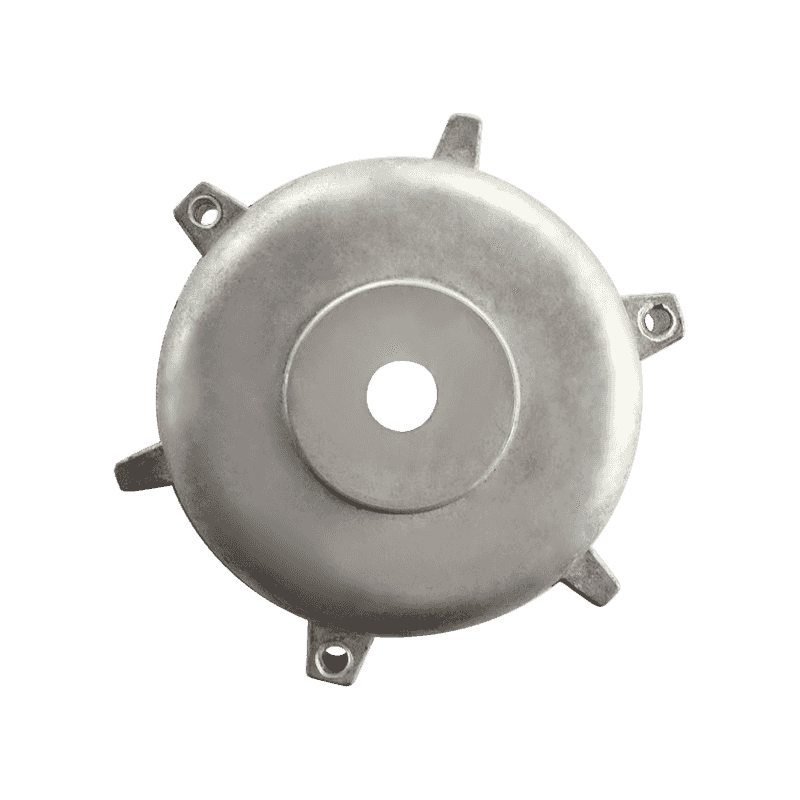

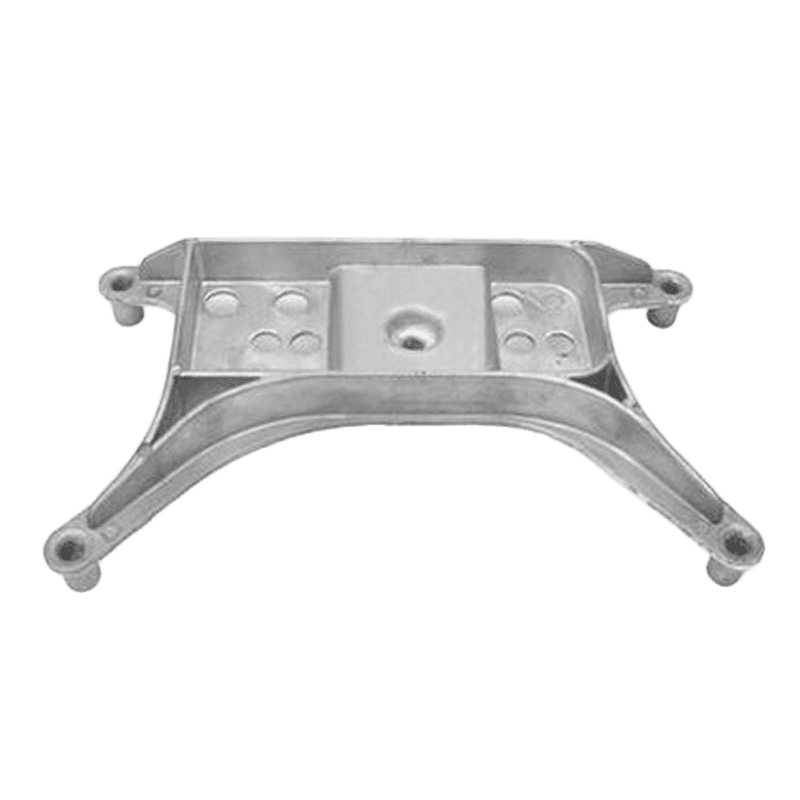

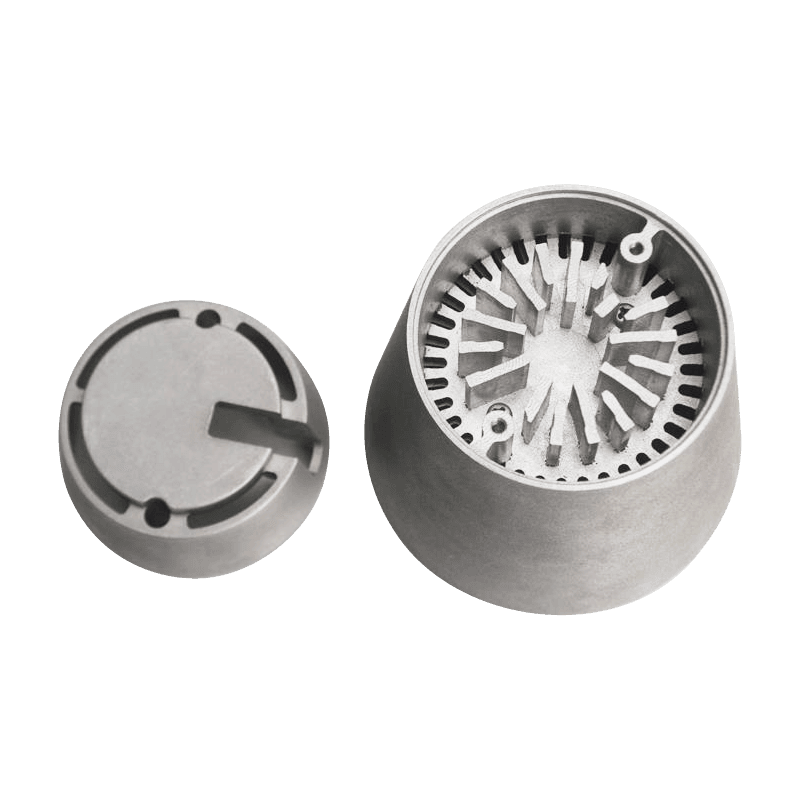

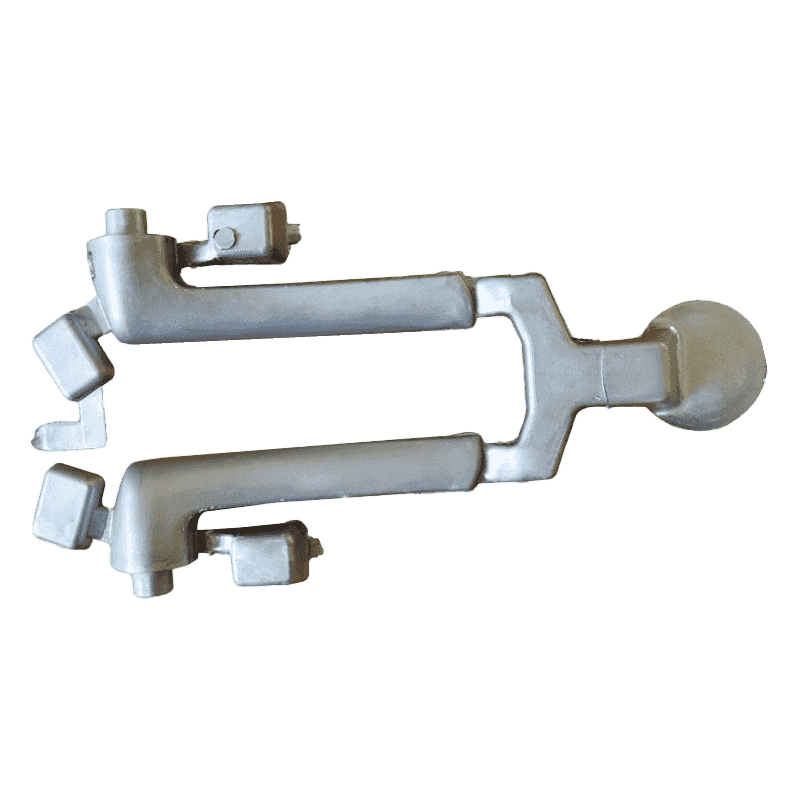

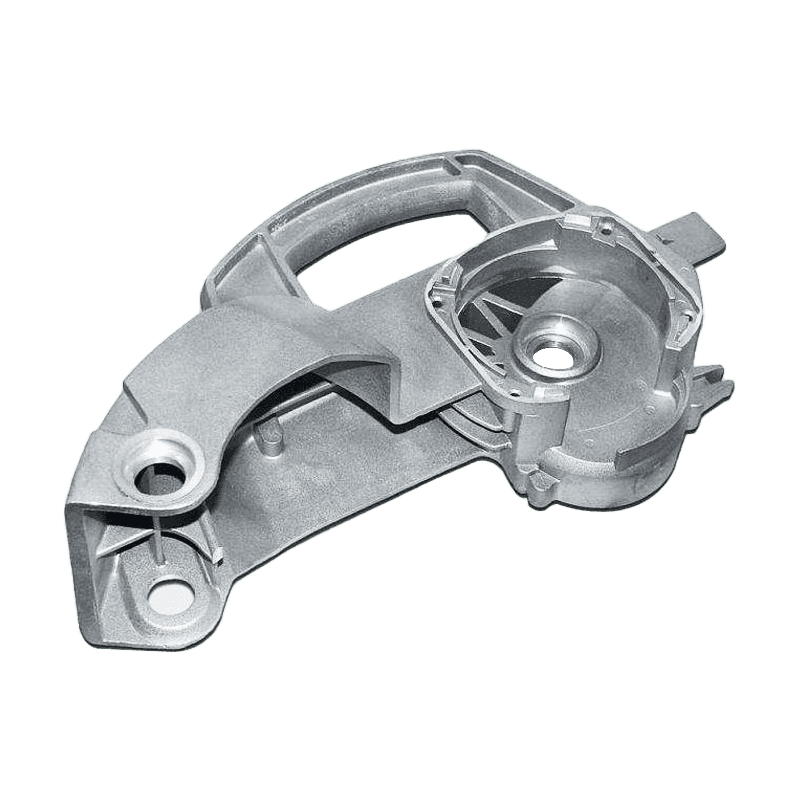

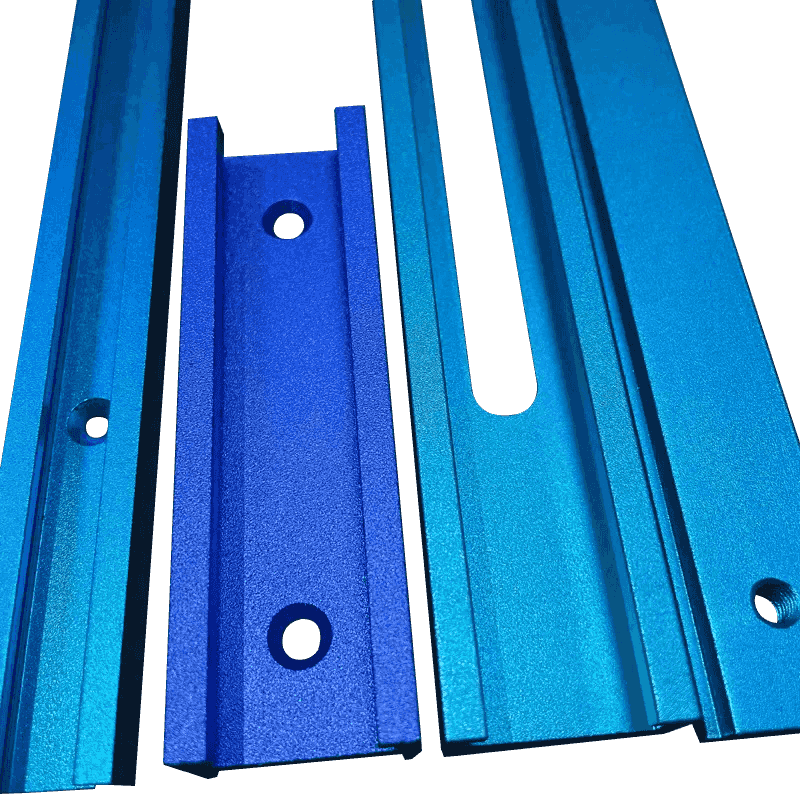

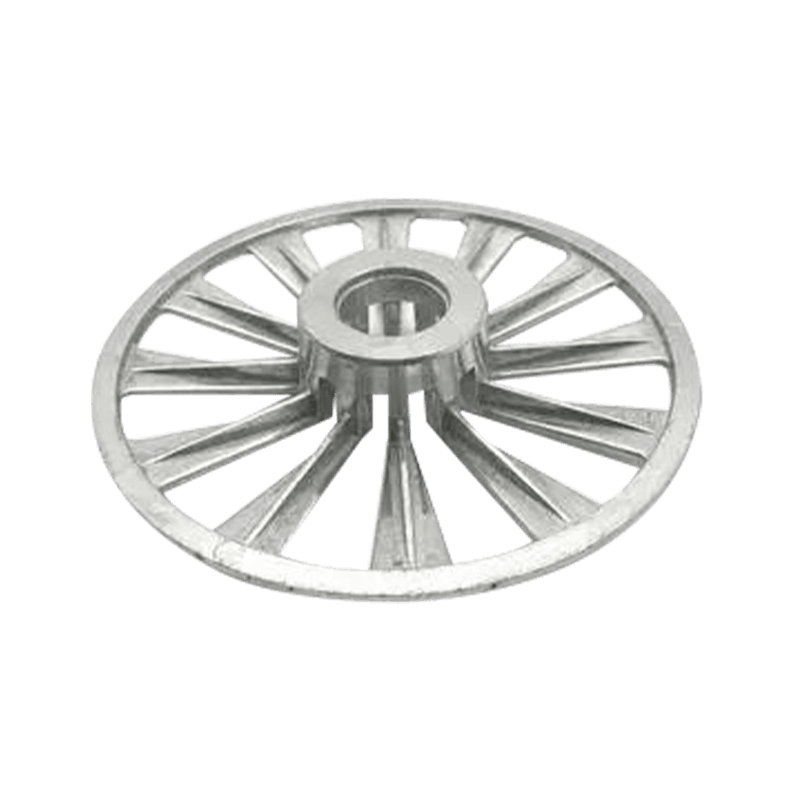

Aluminum alloy die casting is an efficient and high-precision manufacturing method suitable for the production of automotive parts with complex geometries. This process can form thin-walled structural parts in one go, which helps to reduce the weight accumulation caused by welding and splicing processes. In addition, the surface quality of die castings is high, which can reduce subsequent processing links and has positive significance for the production rhythm of the whole vehicle.

Representative fields of alternative applications

Aluminum alloy die castings are currently used in engine housings, gearbox housings, door inner frames, seat brackets, instrument panel brackets and other fields. These parts are usually sensitive to weight, but do not require excessive impact loads. With the improvement of manufacturing technology, more high-strength aluminum alloys are gradually applied to some structural parts, providing the possibility of replacing steel.

Strength and toughness are key factors

To effectively replace steel parts, aluminum alloy parts must not only be light, but also reliable enough. This requires die-casting parts to have good strength, rigidity and toughness. Modern aluminum alloy formulas have been continuously optimized and have a certain load-bearing capacity. At the same time, with the help of structural optimization design, parts can withstand greater forces without increasing the volume, thus meeting actual use needs.

Trade-off between cost and environmental factors

Although the raw material cost and processing cost of aluminum alloy materials may be slightly higher than that of steel, its energy-saving effect and recyclability in the life cycle of the vehicle bring better economic and environmental value. With the scale and automation of production processes, the cost difference is gradually narrowing, making it more popular.

Application prospects and development direction

The replacement of steel parts with aluminum alloy die-castings is a gradual process involving many factors such as material properties, process level, and design concept. At present, it has high feasibility in non-load-bearing parts. With the promotion of high-strength aluminum alloy materials and new die-casting technology in the future, its application scope is expected to be further expanded. The improvement of fuel efficiency and endurance brought about by vehicle weight reduction will also promote the continuous application of aluminum alloy materials in automobile manufacturing.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский