Do aluminum profile heat dissipation fittings have anti-corrosion and oxidation-resistant treatments?

04-12-2025Material Composition of Aluminium Profile Heat Dissipation Fittings

Aluminium profile heat dissipation fittings are typically made from high-quality aluminum alloys chosen for their thermal conductivity and mechanical strength. The alloy composition impacts not only the heat dissipation performance but also the susceptibility to corrosion and oxidation. Commonly used alloys contain elements such as silicon and magnesium, which enhance corrosion resistance and improve the structural integrity of the fittings. Proper selection of aluminum alloy is a fundamental step in ensuring that the aluminium profile heat dissipation fittings maintain long-term functionality in various environmental conditions.

Surface Treatment Methods

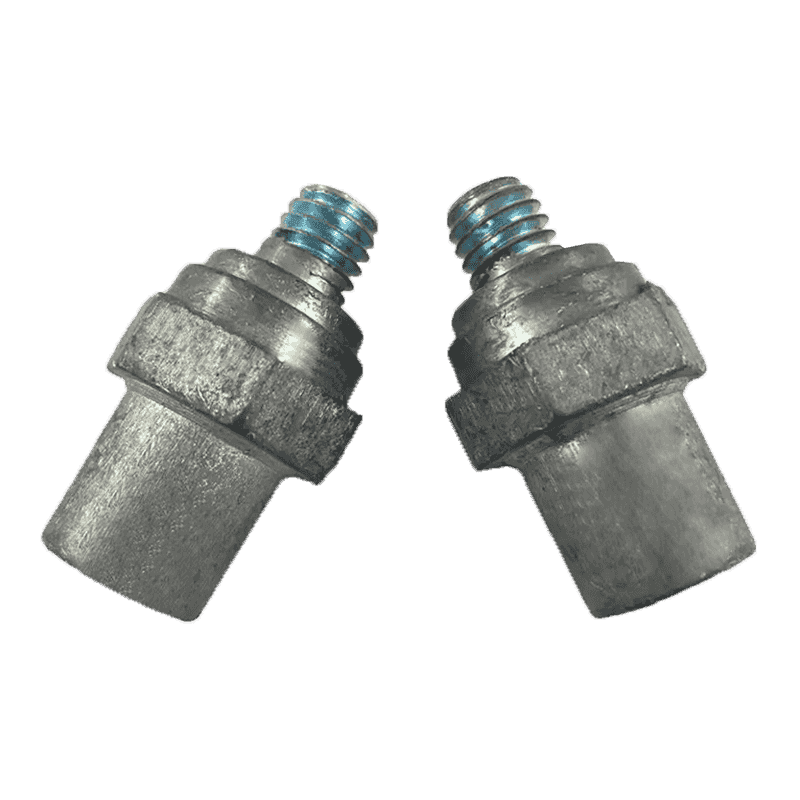

Surface treatment is crucial for protecting aluminium profile heat dissipation fittings from corrosion and oxidation. Treatments such as anodizing, powder coating, and chemical passivation create a protective layer on the aluminum surface. Anodizing produces a dense oxide layer that increases resistance to environmental factors, including moisture and chemical exposure. Powder coating provides a physical barrier that prevents direct contact with corrosive agents, while chemical passivation enhances the natural oxide layer on the aluminum surface. These treatments collectively improve the durability and lifespan of aluminium profile heat dissipation fittings in demanding applications.

Corrosion Resistance Mechanisms

The corrosion resistance of aluminium profile heat dissipation fittings is achieved through both intrinsic material properties and applied surface treatments. Aluminum naturally forms a thin oxide layer when exposed to air, which offers initial protection against corrosion. Surface treatments like anodizing reinforce this layer and prevent the formation of pits or localized corrosion sites. Additionally, high-quality coatings act as a barrier to prevent exposure to water, salts, and other corrosive elements. Together, these mechanisms help maintain the structural and thermal performance of the fittings over time, even in challenging environments.

Oxidation Resistance in Varied Environments

Aluminium profile heat dissipation fittings are often used in settings where they are exposed to fluctuating temperatures, humidity, and air pollutants. Oxidation resistance is essential to prevent the formation of unwanted oxide deposits that can compromise heat transfer efficiency. Treatments such as anodizing and chemical passivation slow down the oxidation process and maintain a uniform surface, ensuring consistent thermal conductivity. Properly treated fittings retain both their appearance and functional performance in both indoor and outdoor environments.

Durability and Maintenance

The durability of aluminium profile heat dissipation fittings is closely linked to their corrosion and oxidation resistance. Regular maintenance, including cleaning and visual inspection, helps identify any surface degradation early. Protective coatings can be repaired or reapplied if minor wear occurs, extending the service life of the fittings. By combining durable materials with appropriate treatments, aluminium profile heat dissipation fittings provide reliable heat management for electronic components and other applications that demand long-term stability.

Performance Comparison of Surface Treatments

Different surface treatments offer varying levels of protection against corrosion and oxidation. The table below summarizes common treatment methods for aluminium profile heat dissipation fittings and their expected performance characteristics.

| Surface Treatment | Method | Corrosion Resistance | Oxidation Resistance | Maintenance Requirements |

|---|---|---|---|---|

| Anodized | Electrochemical oxidation | High | High | Low |

| Powder Coated | Electrostatic application and curing | Moderate to High | Moderate | Moderate |

| Chemical Passivation | Acid or alkaline treatment | Moderate | High | Low |

| Untreated | None | Low | Low | High |

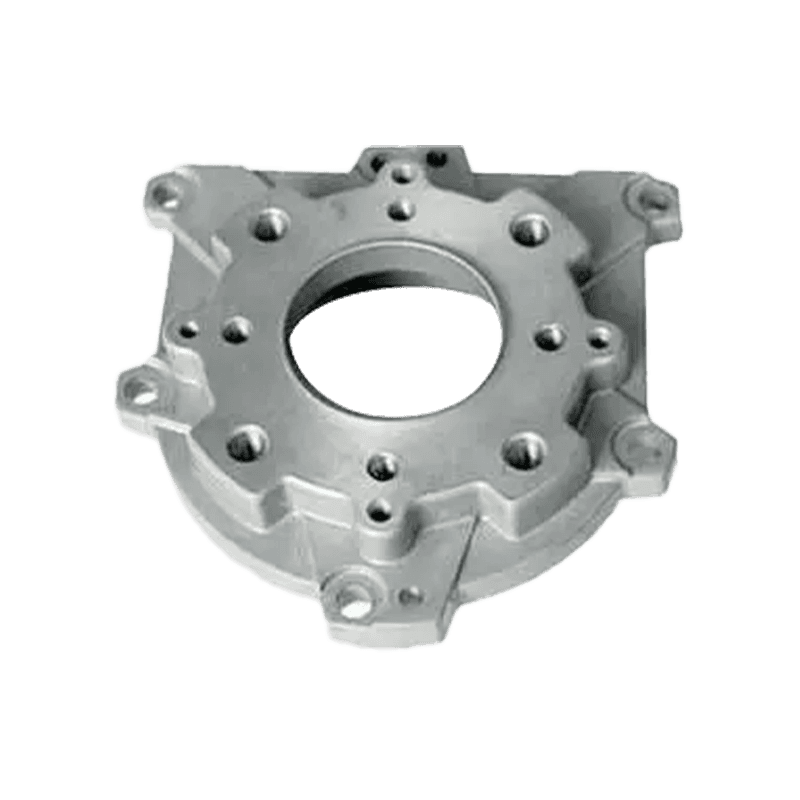

Applications and Environmental Considerations

Aluminium profile heat dissipation fittings are widely used in electronics, LED lighting, automotive, and industrial machinery. In these applications, exposure to moisture, salts, and temperature variations can accelerate corrosion and oxidation if proper treatments are not applied. Understanding the environmental conditions helps determine the most suitable surface treatment to ensure longevity. For example, outdoor LED fixtures benefit significantly from anodized or powder-coated fittings, while indoor electronic devices may require only light passivation for adequate protection.

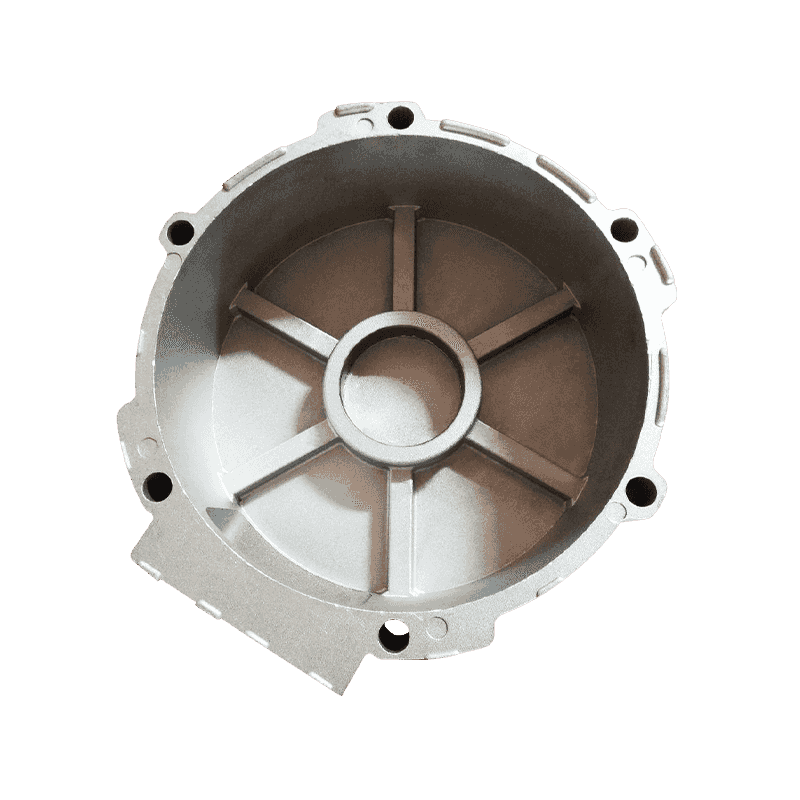

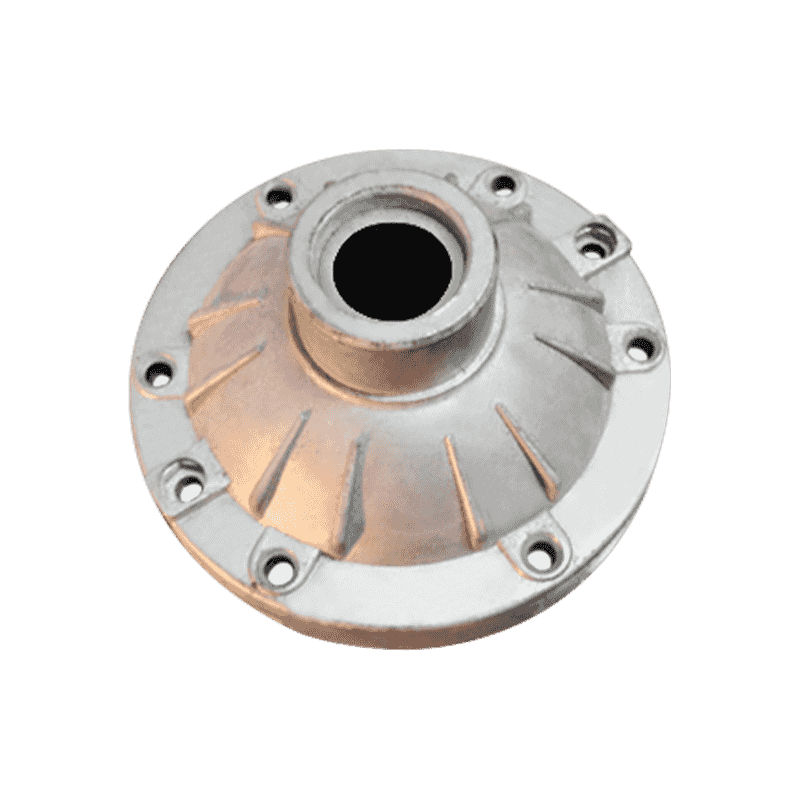

Design Considerations for Heat Dissipation and Protection

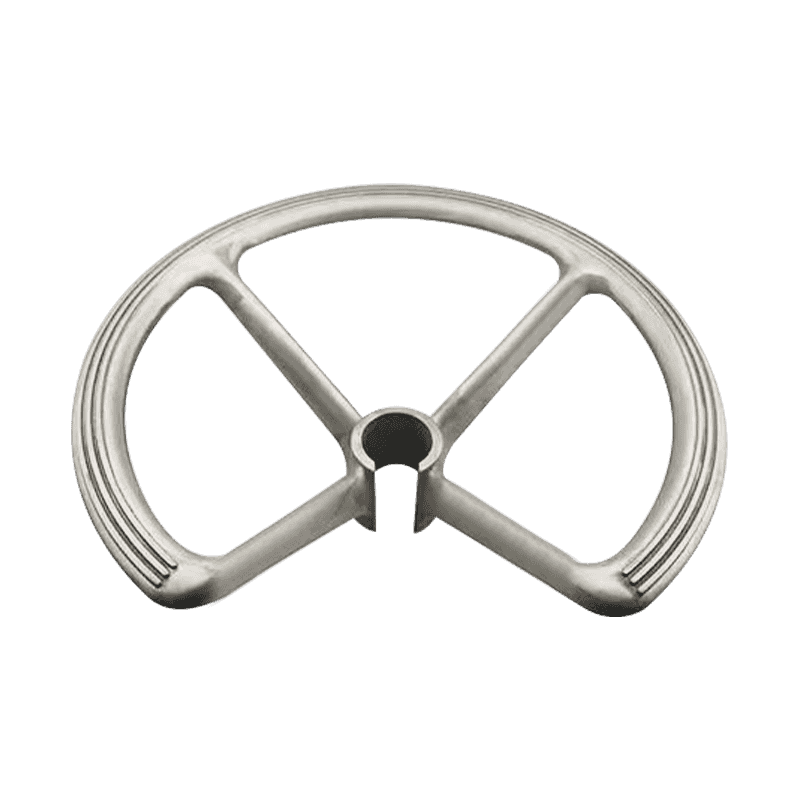

When designing aluminium profile heat dissipation fittings, engineers must balance thermal performance with corrosion and oxidation resistance. Features such as fins, grooves, and surface area optimizations improve heat transfer but may also create areas prone to moisture accumulation. Applying consistent and thorough surface treatments ensures that all exposed areas maintain protective barriers. This approach allows the aluminium profile heat dissipation fittings to function effectively while resisting environmental degradation.

Standards and Compliance

Aluminium profile heat dissipation fittings often need to meet industry standards regarding corrosion resistance, thermal conductivity, and mechanical strength. Compliance with these standards involves testing for exposure to moisture, chemical agents, and temperature cycling. Properly treated and tested fittings can provide reliable performance, ensuring that devices utilizing these components maintain operational efficiency and safety. Adhering to standards also provides confidence in the durability and long-term usability of aluminium profile heat dissipation fittings across various applications.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский