How to ensure the strength and stability of aluminum profile electronic fittings?

17-06-2025Material selection and alloy ratio

The strength and stability of aluminum profile electronic fittings are first related to the aluminum alloy material used. Different aluminum alloy materials have different mechanical properties. Usually, aluminum profile electronic fittings mostly use aluminum alloys 6063, 6061, 7075, etc. These alloys not only have good strength, but also have good corrosion resistance and processability.

Other elements added to the alloy, such as silicon, magnesium, copper, zinc, etc., can significantly improve the strength and hardness of aluminum profiles. For example, 6061 aluminum alloy contains more silicon and magnesium elements, which can obtain better strength and corrosion resistance after heat treatment, and is suitable for applications requiring high strength.

Heat treatment process

Heat treatment process is the key to improving the strength and stability of aluminum profiles. During the manufacturing process, aluminum alloys can be improved through different heat treatment processes to improve their internal organizational structure and thus improve their mechanical properties. Common heat treatment methods include dissolution treatment, artificial aging, etc.

Dissolution treatment: Through high-temperature heating, the alloying elements in the aluminum alloy are evenly distributed, thereby enhancing the strength of the aluminum profile.

Artificial aging: The aluminum profiles after dissolution treatment are aged at a specific temperature to further enhance their mechanical properties.

Through these heat treatment processes, aluminum profiles can obtain higher tensile strength and bending resistance, thereby enhancing their overall stability.

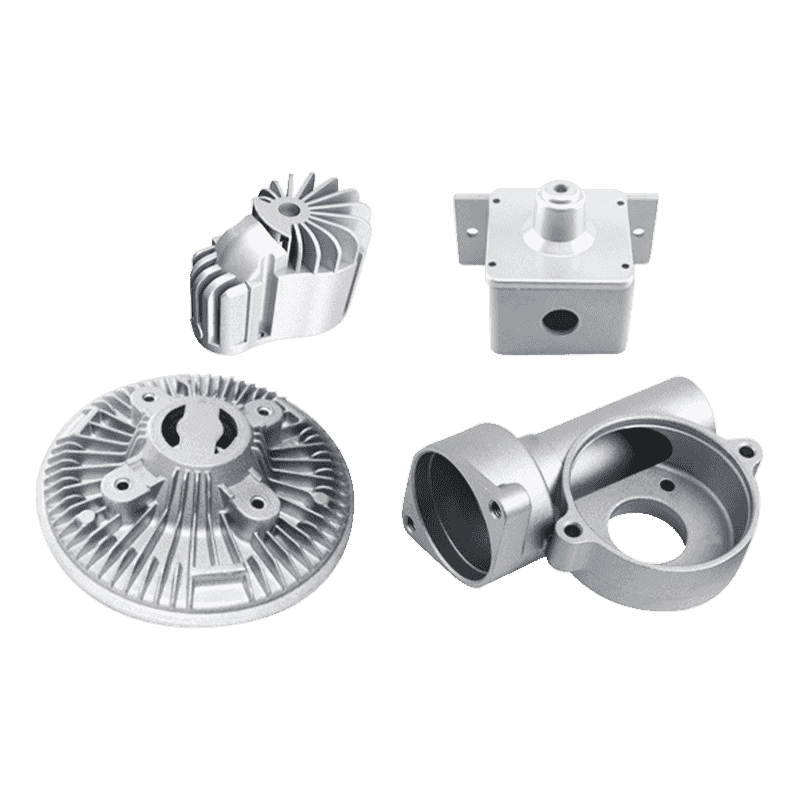

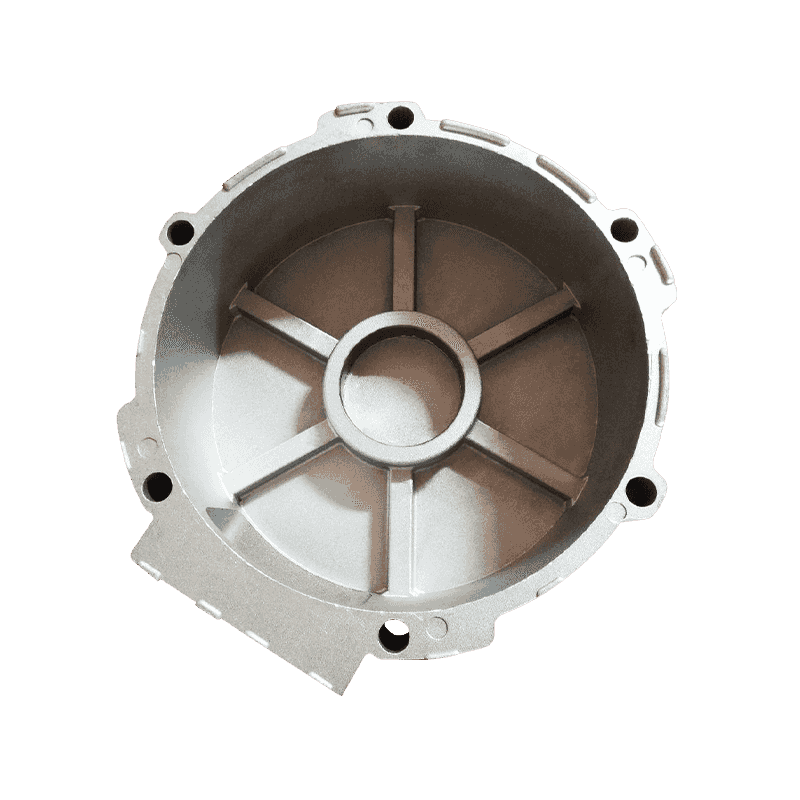

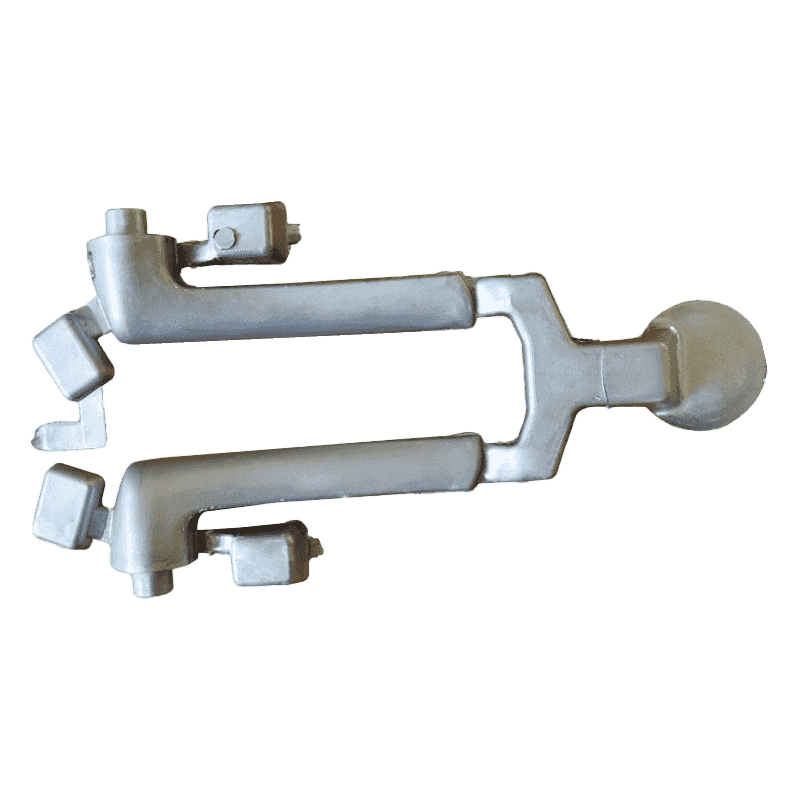

Structural design and wall thickness control

The design of aluminum profile electronic fittings is crucial to their strength and stability. During the design process, reasonable structural optimization can effectively improve the bearing capacity of fittings. For example, the wall thickness control of aluminum profile fittings should be selected according to the use requirements. Too thin wall thickness will cause the fittings to deform or break when subjected to greater force, while too thick wall thickness will increase production costs and weight.

Reasonable rib design, reinforcement rib setting, etc. can also effectively improve the strength of aluminum profiles, making them more stable when subjected to force. Especially in some high-load electronic equipment, reasonable structural design can maximize the stability of aluminum profiles.

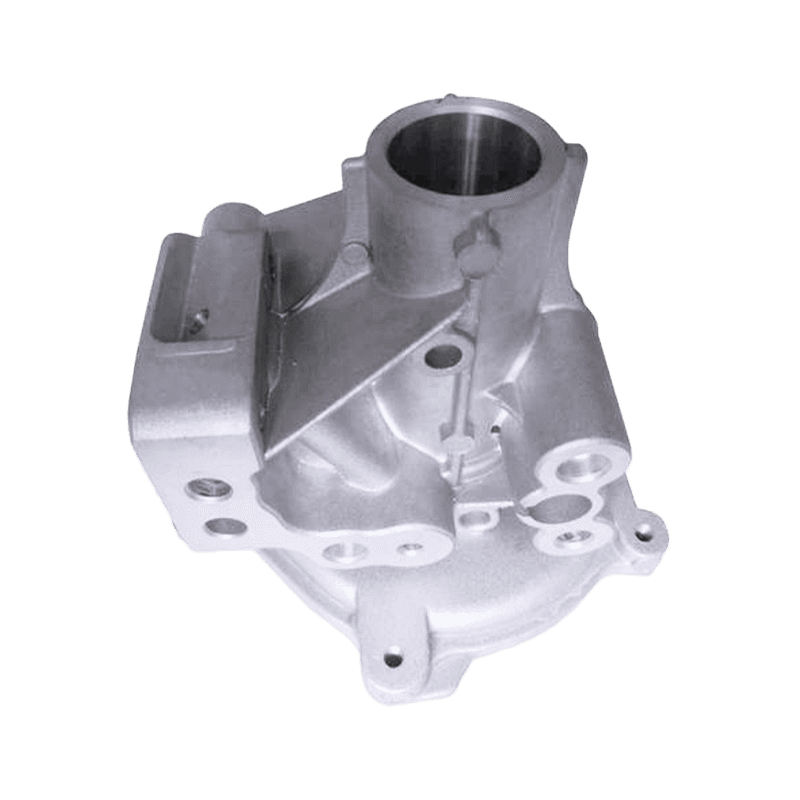

Precision machining and surface treatment

The machining accuracy of aluminum profile electronic fittings directly affects their strength and stability. During the production process, precision processing technologies such as CNC machining and laser cutting are used to ensure that the dimensional tolerance of aluminum profiles is controlled within a reasonable range, which can effectively avoid deformation or rupture of fittings caused by dimensional errors in actual use.

Surface treatment processes such as anodizing and electroplating can not only improve the corrosion resistance of aluminum profiles, but also improve their surface hardness and anti-friction ability. Aluminum profile fittings that have undergone these treatments can better resist the erosion of the external environment and extend their service life.

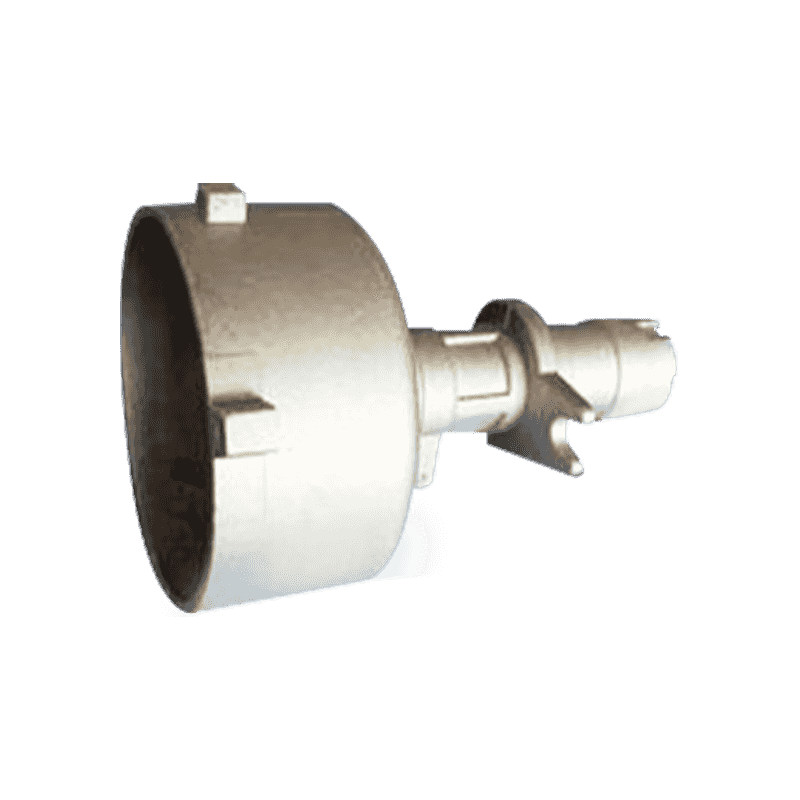

Strengthening connection methods

Aluminum profile electronic fittings usually involve connections with other components, such as bolt connections, welding, riveting, etc. Choosing a suitable connection method has an important impact on the strength and stability of fittings. For example, bolt connections can provide higher disassembly convenience, but their strength needs to be guaranteed by reasonable thread design and appropriate torque. Welding connections provide stronger tensile strength, but the welding process needs to be fine to avoid stress concentration at the weld.

In some applications, aluminum profile electronic fittings may be subjected to greater vibration or external force impact. Reasonable selection and optimization of connection methods can effectively improve the stability of the overall structure.

Adaptability to environmental factors

The stability of aluminum profile electronic fittings depends not only on its internal materials and structural design, but also on the external environment in which it is located. For example, environmental factors such as temperature changes, humidity, and salt spray will affect the performance of aluminum profiles. In high or low temperature environments, the strength and hardness of aluminum alloys may change, so it is necessary to consider the impact of environmental conditions on aluminum profiles and select appropriate alloy materials and heat treatment methods.

The corrosion resistance of aluminum profiles will also affect their stability in long-term use. In humid or highly corrosive environments, the surface of aluminum profiles needs additional protective treatment, such as anodizing, to improve its corrosion resistance and ensure the stability of fittings in long-term use.

Quality control and testing

Strict quality control is essential in the production process of aluminum profile electronic fittings. By implementing multiple testing methods during the production process, such as mechanical property testing, surface quality inspection, dimensional accuracy testing, etc., it can be ensured that each batch of aluminum profile fittings meets the design requirements and has sufficient strength and stability.

High-intensity fatigue tests and tensile tests on products before leaving the factory can effectively evaluate the performance of fittings under extreme conditions and ensure their reliability in actual use.

Regular inspection and maintenance during use

Although strength and stability have been taken into consideration in the design and production of aluminum profile electronic fittings, regular inspection and maintenance should not be ignored during use. Especially in equipment with high load or long-term use, fittings should be regularly checked for wear, deformation or looseness, and repaired or replaced in a timely manner. This can ensure the long-term and stable operation of aluminum profile electronic fittings and avoid major failures due to minor problems.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский