Is the corrosion resistance of die-cast aluminum alloy automotive parts sufficient in the automotive usage environment?

03-09-2025Introduction to Die-Cast Aluminum Alloy Automotive Parts

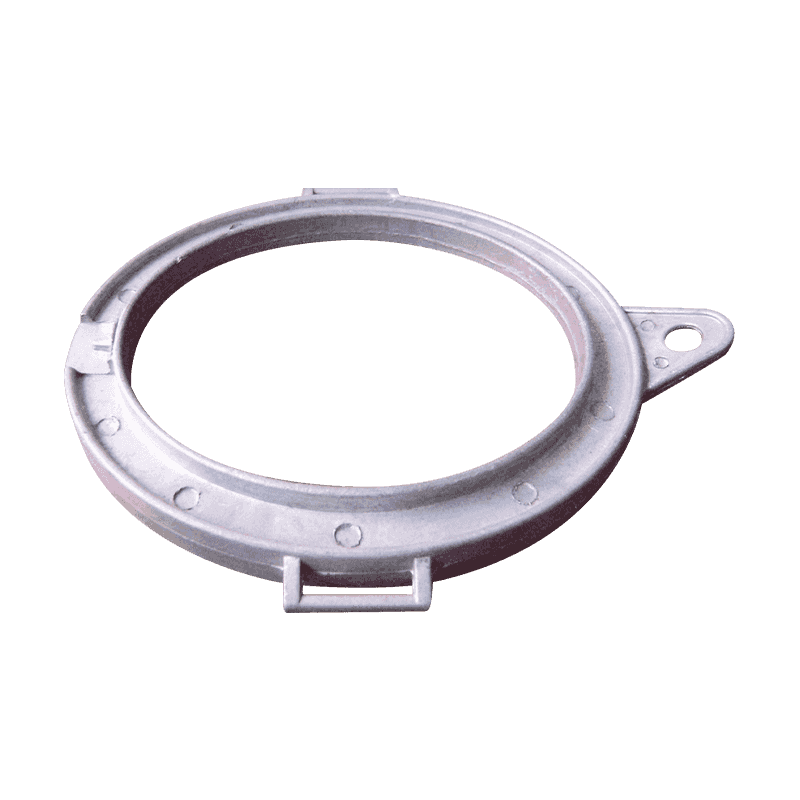

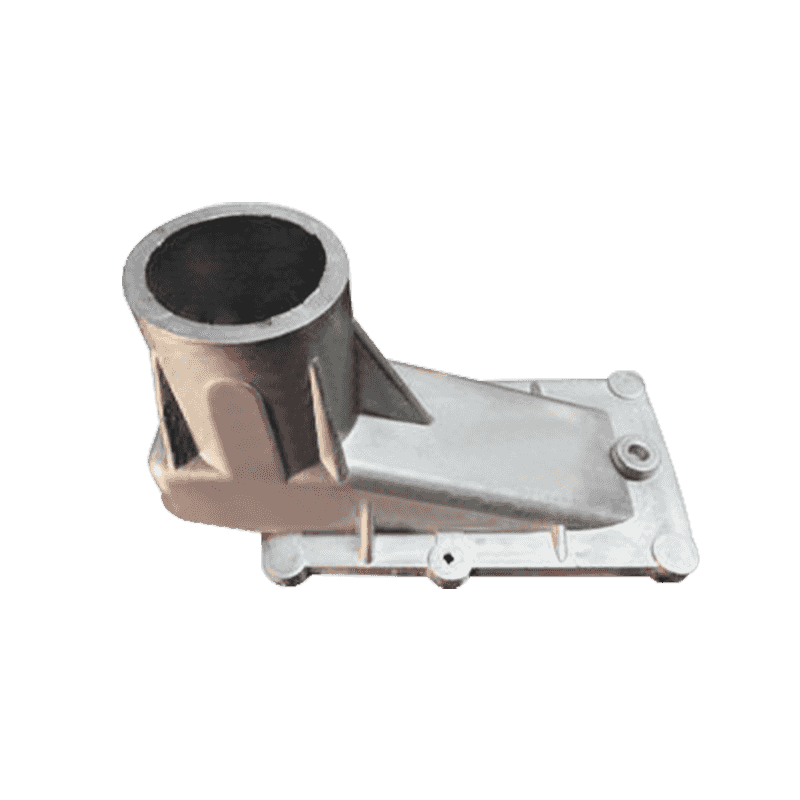

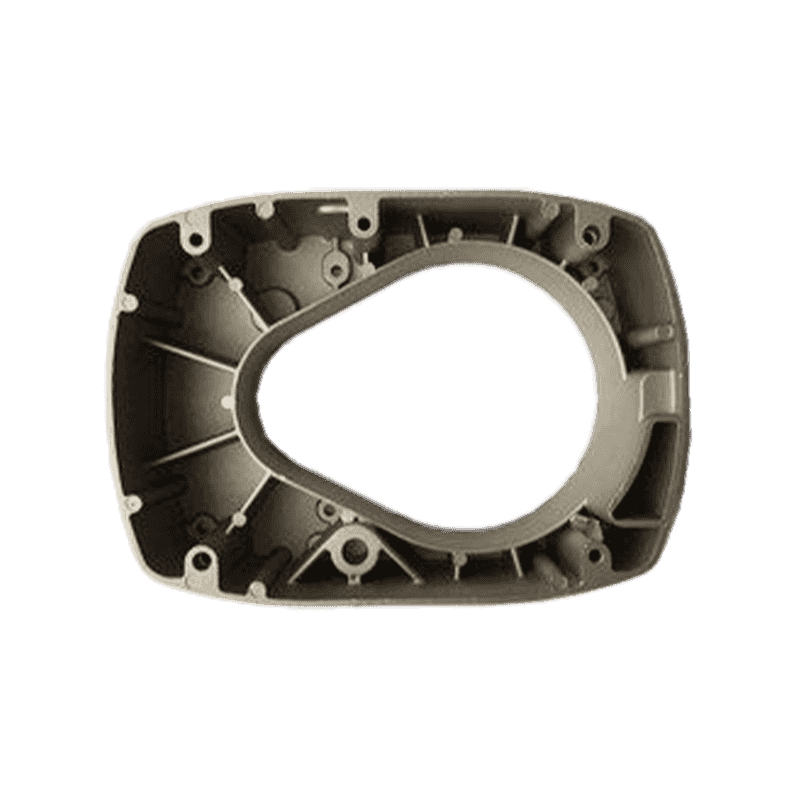

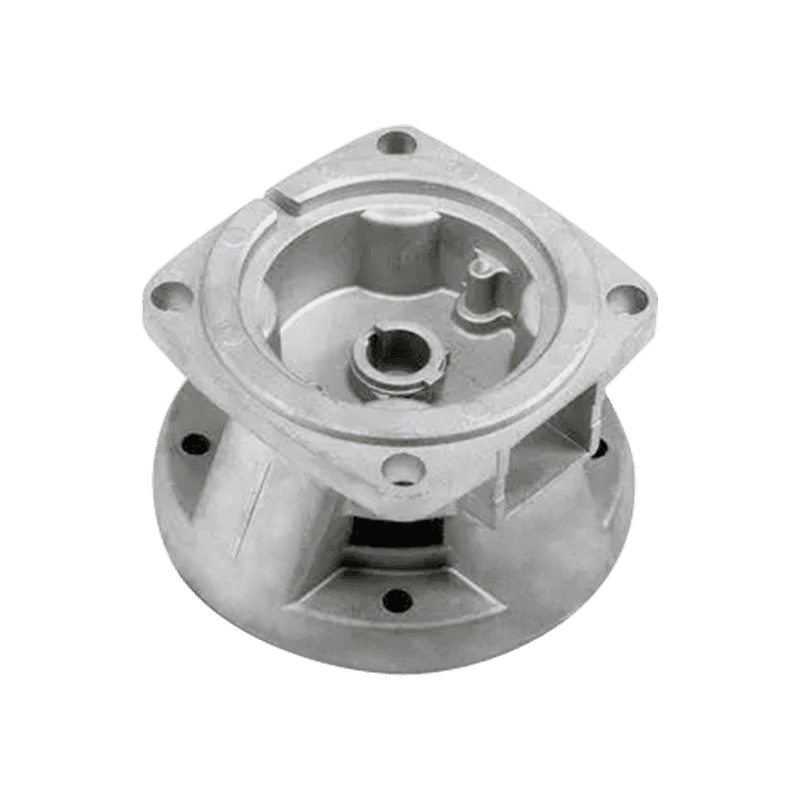

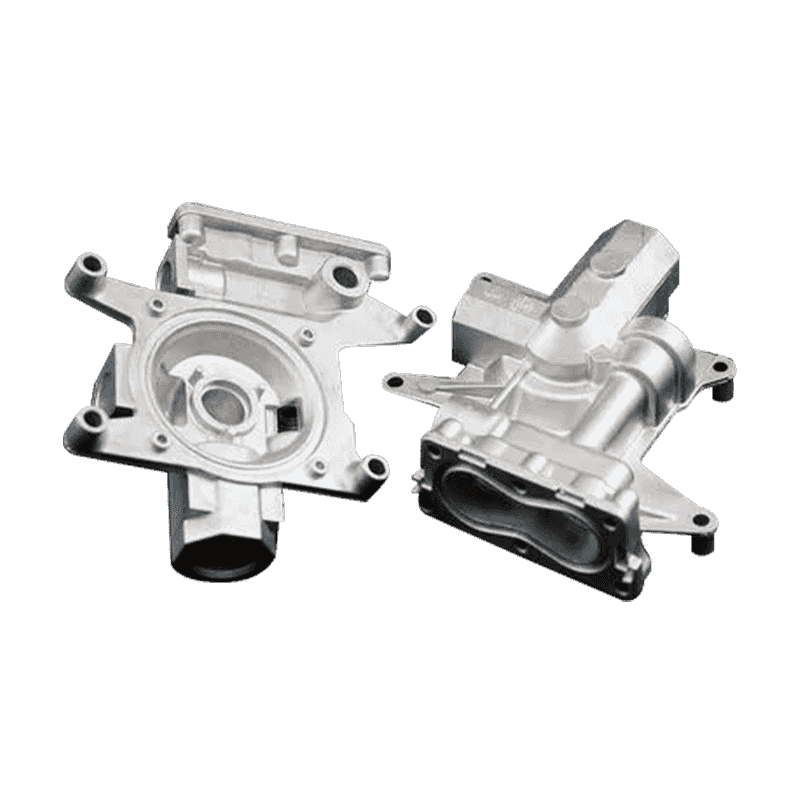

Die-cast aluminum alloy automotive parts are widely used in the automotive industry due to their light weight, design flexibility, and ability to form complex shapes. These parts are employed in engine components, transmission housings, chassis parts, and body structures. One critical property that affects their long-term performance is corrosion resistance, particularly since automotive parts are exposed to varying environmental conditions, including moisture, road salt, temperature changes, and chemical contaminants. Evaluating whether die-cast aluminum alloys provide sufficient corrosion resistance in automotive usage environments requires a detailed understanding of their material properties, manufacturing processes, and protective measures.

Material Composition and Corrosion Resistance

Aluminum alloys used in die casting typically include silicon, magnesium, copper, or other alloying elements to improve strength and castability. Silicon, in particular, enhances fluidity and reduces shrinkage during casting, but it also influences corrosion behavior. Magnesium can improve mechanical properties but may make the alloy more susceptible to certain forms of corrosion if not properly treated. Copper content can increase strength but may reduce corrosion resistance. The balance of these elements, combined with proper heat treatment, affects the ability of the aluminum alloy to resist oxidation and degradation in automotive conditions.

| Alloy Type | Typical Elements | Corrosion Behavior | Common Automotive Use |

|---|---|---|---|

| Al-Si | Aluminum, Silicon | Moderate resistance; may form protective oxide layer | Engine covers, housings |

| Al-Si-Mg | Aluminum, Silicon, Magnesium | Improved corrosion resistance after heat treatment | Chassis and suspension components |

| Al-Cu | Aluminum, Copper | Reduced corrosion resistance in moist environments | Structural components requiring high strength |

| Al-Si-Cu-Mg | Aluminum, Silicon, Copper, Magnesium | Balanced mechanical properties with controlled corrosion | Transmission housings, engine parts |

Factors Affecting Corrosion in Automotive Environments

Automotive environments present multiple challenges for materials, including exposure to road salts, moisture, and atmospheric pollutants. Salt from winter roads accelerates pitting corrosion, particularly in areas where water can accumulate. Temperature fluctuations cause expansion and contraction, which may initiate micro-cracks in the protective oxide layer. Additionally, chemical contaminants such as acids or cleaning agents may interact with the aluminum surface. The specific design and location of the die-cast component also influence corrosion risk; areas with crevices, thin walls, or joints are more prone to localized corrosion.

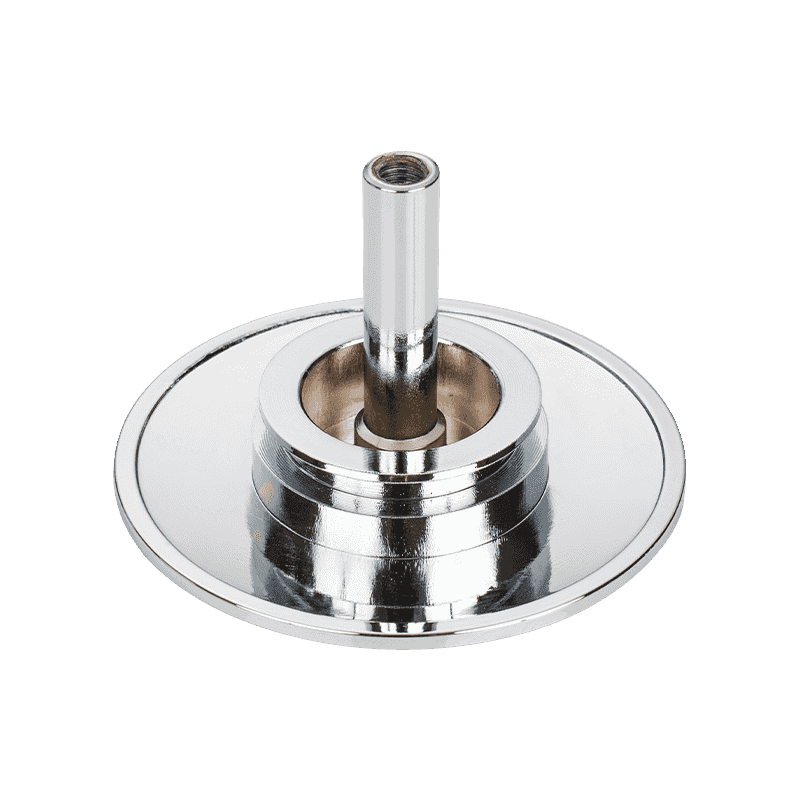

Protective Mechanisms of Die-Cast Aluminum

Die-cast aluminum alloys form a naturally occurring oxide layer on their surface when exposed to air. This layer can act as a barrier against further oxidation and corrosion. However, the effectiveness of this natural oxide layer depends on the alloy composition and environmental conditions. In automotive applications, additional protective measures are often employed, including anodizing, chemical conversion coatings, and powder coating. Anodizing thickens the oxide layer and can provide improved resistance to pitting, while chemical conversion coatings such as chromate treatments enhance adhesion of paint and additional coatings. These surface treatments are especially important in components exposed to direct contact with water and salt.

| Protection Type | Mechanism | Application Example | Effectiveness |

|---|---|---|---|

| Natural Oxide Layer | Forms spontaneously in air | All aluminum surfaces | Moderate in dry conditions |

| Anodizing | Electrochemical thickening of oxide | Engine covers, decorative trims | Reduces pitting, improves durability |

| Chemical Conversion Coating | Thin protective layer using chemical treatment | Chassis components | Enhances corrosion resistance and paint adhesion |

| Powder Coating | Paint-like finish cured onto surface | Exterior trims, housings | Protects against moisture and mechanical wear |

Influence of Die-Casting Process on Corrosion Resistance

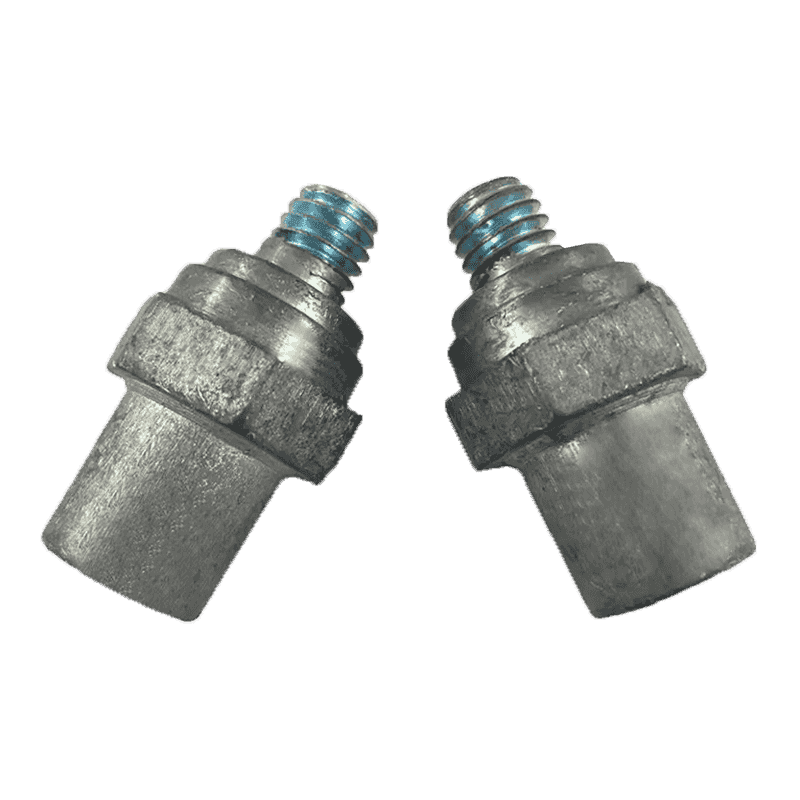

The die-casting process itself can influence corrosion resistance. Factors such as casting temperature, mold design, and cooling rate determine the microstructure of the alloy. Rapid cooling during die casting may result in fine microstructures that can improve mechanical strength but may also create regions with different electrochemical potential, increasing the risk of localized corrosion. Porosity, a common feature in die-cast components, can allow water or chemicals to penetrate the interior, initiating corrosion from inside the part. Therefore, careful control of the die-casting parameters, including mold filling speed and temperature control, is essential to minimize porosity and enhance corrosion resistance.

Environmental Testing and Standards

Automotive manufacturers perform extensive testing to evaluate the corrosion resistance of aluminum die-cast components. Common tests include salt spray (fog) testing, cyclic corrosion testing, and exposure to humidity and temperature cycles. Salt spray testing simulates road salt exposure and evaluates the onset of pitting or surface degradation. Cyclic corrosion testing replicates fluctuating humidity and temperature, closer to real-world conditions. Automotive standards, such as ASTM B117 for salt spray testing and ISO 9227, provide benchmarks for evaluating performance. Results from these tests help manufacturers identify potential weaknesses and determine the necessity of additional surface treatments.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский