Does lead die casting require special cooling or exhaust design?

12-11-2025Importance of Cooling and Exhaust Systems in Lead Die Casting

Cooling and exhaust systems in lead die casting play key roles in stabilizing the casting cycle, managing heat distribution, and supporting consistent mold performance. Although lead melts at a relatively low temperature compared with many other metals, the casting process still generates localized heat that must be managed to prevent thermal deformation or uneven filling. Proper exhaust design is also necessary because molten lead releases fumes and gases that must be directed away from both the mold cavity and the working environment. In industrial practice, the design of cooling paths and exhaust channels directly influences production efficiency and the structural stability of finished castings. Without appropriate management, issues such as incomplete filling, porosity, thermal fatigue, and surface defects may occur. These considerations highlight how cooling and exhaust arrangements form an integral part of lead die casting engineering and support stable, repeatable production conditions.

Heat Characteristics of Lead and Their Impact on Mold Behavior

Lead’s low melting point and high density give it unique thermal characteristics during casting. While the relatively low temperature requirement reduces energy consumption, the metal still carries significant heat when entering the mold cavity. The mold absorbs this heat quickly, which may cause dimensional expansion or stress accumulation if cooling pathways are insufficient. Additionally, lead solidifies at a slower rate compared with some other alloys, making uniform heat extraction important for preventing shrinkage voids. Consistent mold temperature also supports the predictable flow of molten lead and reduces the likelihood of cold shuts or incomplete transitions between sections. Therefore, even though lead is easier to melt, mold temperature fluctuations must be stabilized through carefully arranged cooling systems.

Typical Cooling System Designs in Lead Die Casting

Cooling systems in lead die casting usually incorporate internal channels within the mold structure. These channels allow water or oil to circulate and remove heat from the mold during each cycle. Designers evaluate mold thickness, cavity geometry, and metal flow paths to determine the placement of these cooling channels. If the cooling is uneven, different sections of the mold may expand at different rates, leading to dimensional inconsistencies. Cooling also affects cycle time because solidified lead must reach a stable temperature before the mold can be opened. Longer cooling times reduce production speed, while insufficient cooling may generate casting defects. Therefore, cooling design is a balance between managing thermal behavior and maintaining efficiency.

Comparison of Common Cooling Media

Cooling systems for lead casting may use different media depending on factory conditions. The table below compares the characteristics of common cooling media. These factors help engineers select appropriate methods based on equipment layout, safety requirements, and production expectations.

| Cooling Medium | Thermal Conductivity | Operating Stability | Typical Application |

|---|---|---|---|

| Water | High | Stable for continuous circulation | General cooling channels in standard molds |

| Oil | Moderate | Useful for temperature-sensitive molds | Slow, controlled cooling requirements |

| Air Cooling | Low | Simple but less efficient | Secondary cooling or low-speed operations |

Exhaust Requirements for Lead Die Casting

Exhaust systems serve two major functions during lead die casting. First, they remove gases trapped in the mold cavity, which prevents porosity and surface marks. When molten lead flows rapidly into the cavity, air must escape to allow smooth filling. Exhaust vents create pathways for this displacement. Second, exhaust systems help direct fumes generated from molten lead away from the working environment. Lead fumes can accumulate during repeated cycles, making proper ventilation essential. A well-designed exhaust structure considers cavity geometry, gating arrangement, and expected metal flow patterns to maintain consistent casting behavior.

Exhaust Vent Placement and Mold Performance

The positioning of vents influences mold filling and the internal structure of the finished product. If vents are placed too far from key filling regions, trapped gases may create internal voids. If vents are too large, metal may leak into the vent channel, causing surface irregularities. The vent size must therefore balance gas release while preventing metal escape. Vents are often incorporated at the parting line or at the ends of long cavity sections where air naturally accumulates. Adjusting vent distribution allows engineers to fine-tune mold behavior, especially for castings with narrow passages or curved geometries. Proper venting supports stable flow during each casting cycle.

Cooling and Exhaust Coordination in Mold Design

Cooling and exhaust systems operate together as part of the mold’s thermal and flow management structure. When cooling channels extract heat effectively, the metal solidifies uniformly, reducing internal stress and helping trapped gases reach vent channels before solidification blocks them. If cooling is uneven, some regions may freeze prematurely, trapping gases and limiting vent function. Similarly, if exhaust systems are not positioned correctly, overheating in certain areas may worsen gas accumulation. Coordinating these systems ensures both temperature stability and airflow balance. Mold designers typically run thermal simulations to assess how cooling paths and vents interact and adjust the layout for consistent casting performance.

Challenges in Cooling Lead Die Casting Molds

Cooling molds for lead casting presents several challenges because excessive cooling may create thermal shock, while insufficient cooling leads to slow cycle times. Lead’s thermal behavior also means that small variations in mold temperature may influence surface finish and structural stability. Molds with complex curves, thin walls, or deep cavities may require segmented cooling channels to maintain uniform temperature distribution. Designers must also consider coolant flow speed, pressure drop, and channel diameter to avoid blockages. The materials used in mold construction influence cooling performance, as some alloys conduct heat more effectively than others. These factors combine to shape the final cooling strategy.

Considerations for Exhaust Design in Lead Casting

Exhaust design must account for lead’s flow characteristics and cavity configuration. Since molten lead flows smoothly but with considerable weight, gas displacement must be efficient to avoid turbulence. Improper exhaust design may cause air pockets or uneven surface texture. Mold surfaces must be maintained to keep vent paths unobstructed, and vent angles must allow air release while minimizing the risk of metal leakage. Engineers often adjust vent depth and width depending on part geometry. Modern die casting equipment may include automated vacuum assist systems, which remove air before injection and reduce the reliance on conventional venting alone.

Table of Common Defects Associated with Poor Cooling or Exhaust Design

The table below summarizes defects linked to inadequate cooling or exhaust systems. Understanding these associations helps guide mold improvements and casting adjustments.

| Defect Type | Likely Cause | Impact on Casting |

|---|---|---|

| Cold Shuts | Uneven heat extraction causing premature solidification | Visible lines on the surface, reduced structural consistency |

| Porosity | Insufficient venting of trapped gases | Internal voids affecting stability |

| Surface Roughness | Inadequate cooling or metal entering vent channels | Textured surface requiring additional finishing |

| Shrinkage Defects | Slow cooling or non-uniform solidification | Localized depressions |

Influence of Cooling Rate on Dimensional Stability

Cooling rate affects how lead contracts as it solidifies. Rapid cooling may cause internal stresses, while slow cooling increases cycle time without improving dimensional control. Consistent cooling supports predictable shrinkage, allowing designers to compensate through mold dimensions. Inaccurate shrinkage prediction may result in parts requiring additional machining. Engineers select cooling channel configuration and flow rate based on the shrinkage characteristics of lead to preserve dimensional stability.

Role of Mold Materials in Cooling Efficiency

Mold materials with high thermal conductivity promote stable cooling patterns. Steel alloys used for lead die casting molds vary in their thermal properties, and surface treatments may also influence heat transfer. When mold materials absorb and dissipate heat uniformly, temperature gradients remain controlled. Material selection thus plays a direct role in cooling strategy. Some molds incorporate inserts made from materials with different thermal properties, allowing targeted temperature management in areas with heavier metal flow or thicker cross-sections.

Environmental and Operational Considerations for Exhaust Systems

Exhaust design cannot focus solely on mold behavior; workplace safety and environmental conditions must also be considered. Lead fumes can accumulate in enclosed spaces, making extraction and ventilation essential. Exhaust channels connected to external filtration or environmental control units help reduce exposure. Mold design must therefore integrate both internal air release pathways and external ventilation infrastructure. Operators must also maintain vents regularly to prevent blockages caused by lead residue.

Integration of Cooling and Exhaust Into Automated Die Casting Cells

As die casting lines become increasingly automated, cooling and exhaust controls are integrated into centralized systems. Sensors may monitor mold temperature and adjust coolant flow automatically. Similarly, automated vacuum or exhaust systems synchronize with injection timing. Integrated control supports consistent casting quality across long production runs. Automated systems also allow predictive maintenance by identifying irregular temperature profiles or vent performance changes before defects occur. This integration demonstrates how cooling and exhaust management extends beyond basic mold design and functions as part of a comprehensive production system.

Considerations for Thick and Thin Wall Lead Castings

Thick wall castings retain heat longer, requiring more intensive cooling pathways to manage solidification. Thin wall castings cool faster but are at greater risk of premature freezing, which may trap gases or limit metal flow. The exhaust and cooling strategies must therefore adjust according to wall thickness. Thick-wall molds may use multiple cooling loops, while thin-wall molds may rely on precision-controlled cooling to avoid thermal gradients. Venting must also adjust to the time available for gas release before solidification occurs.

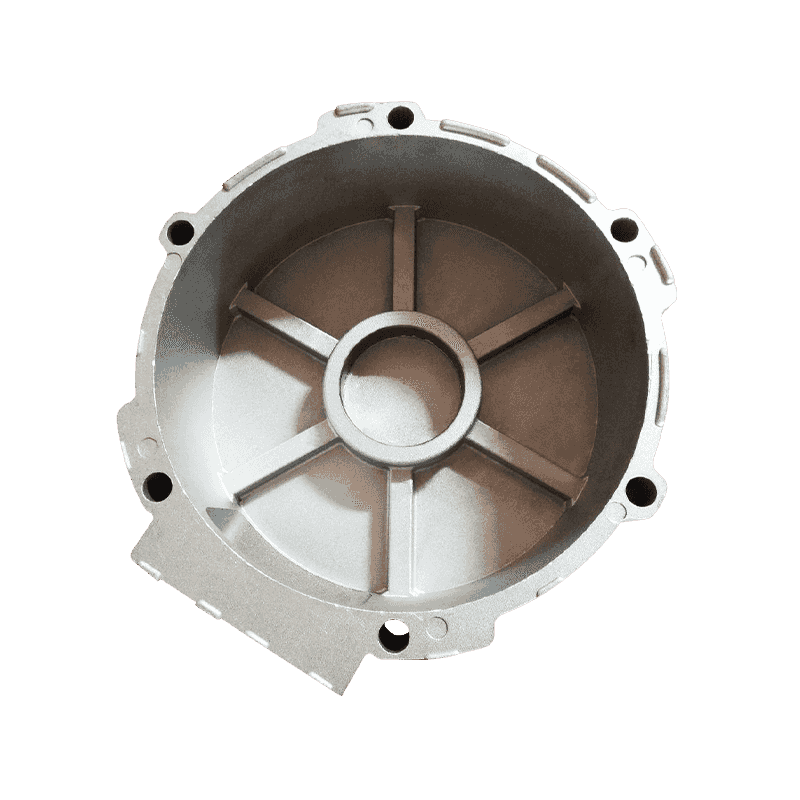

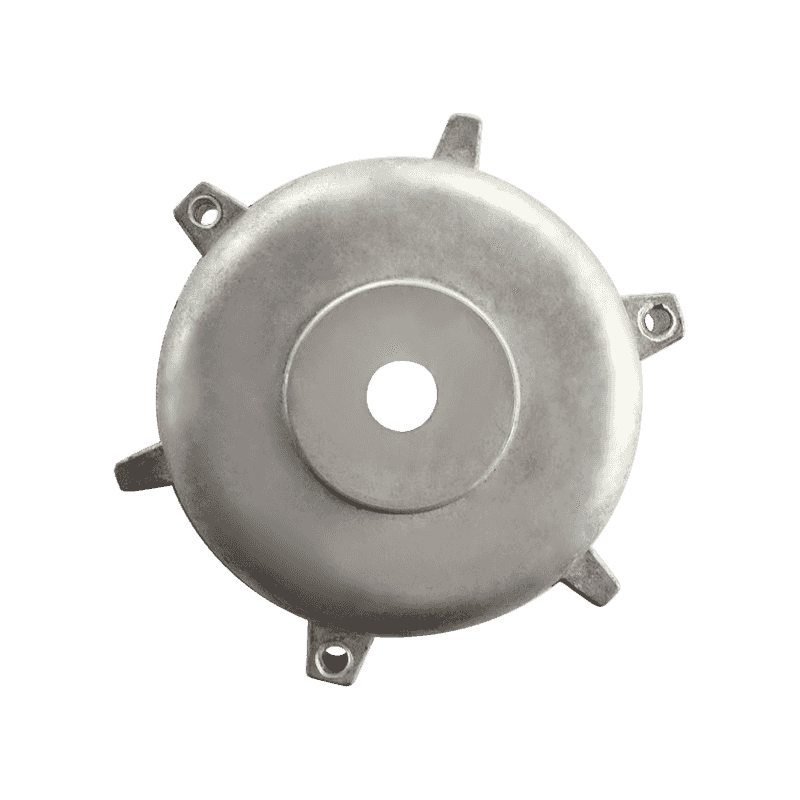

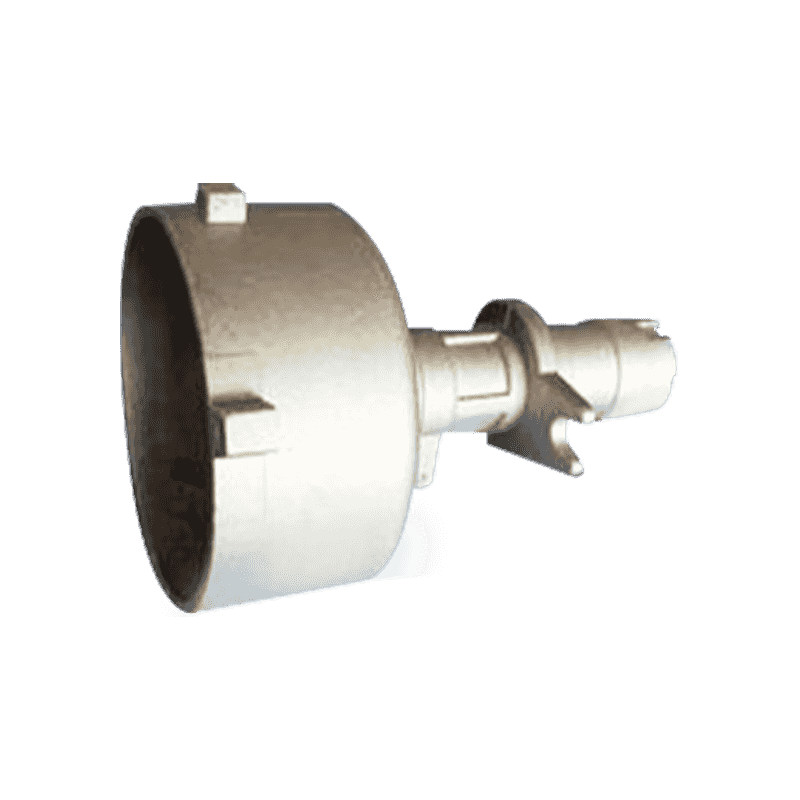

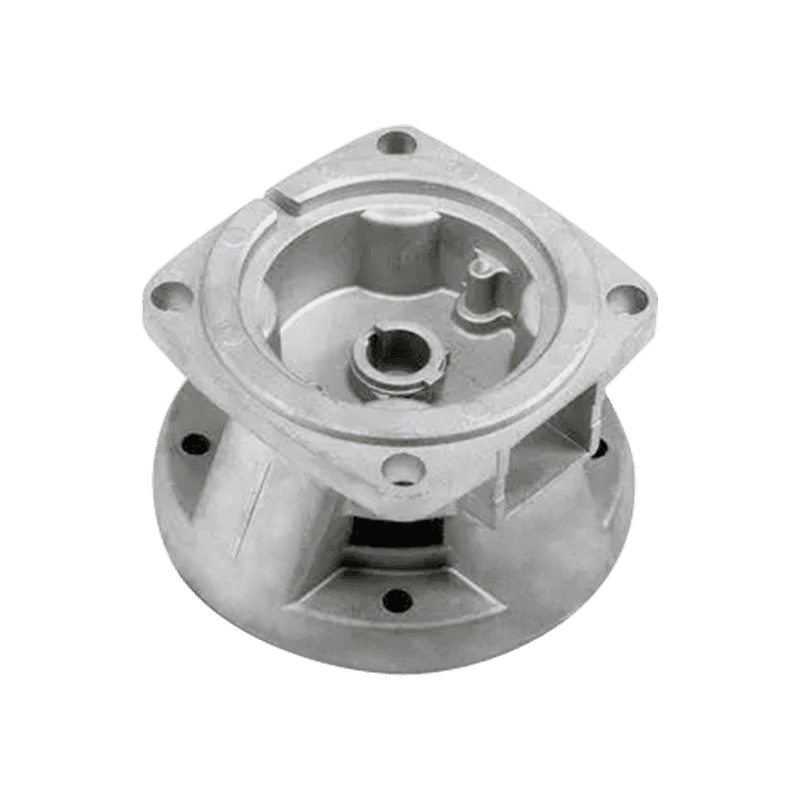

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский