Aluminium Alloy Die Casting Auto Parts: The Quiet Revolution in Car Manufacturing?

22-01-2026In the auto world, not everything that moves is loud. Sometimes the biggest changes come from something you barely notice, like the parts inside the engine bay or the frame sections that hold everything together. Recently, aluminium alloy die casting auto parts have been making a real impact, and the industry is starting to talk about them like they’re the next big thing.

What is aluminium alloy die casting for auto parts?

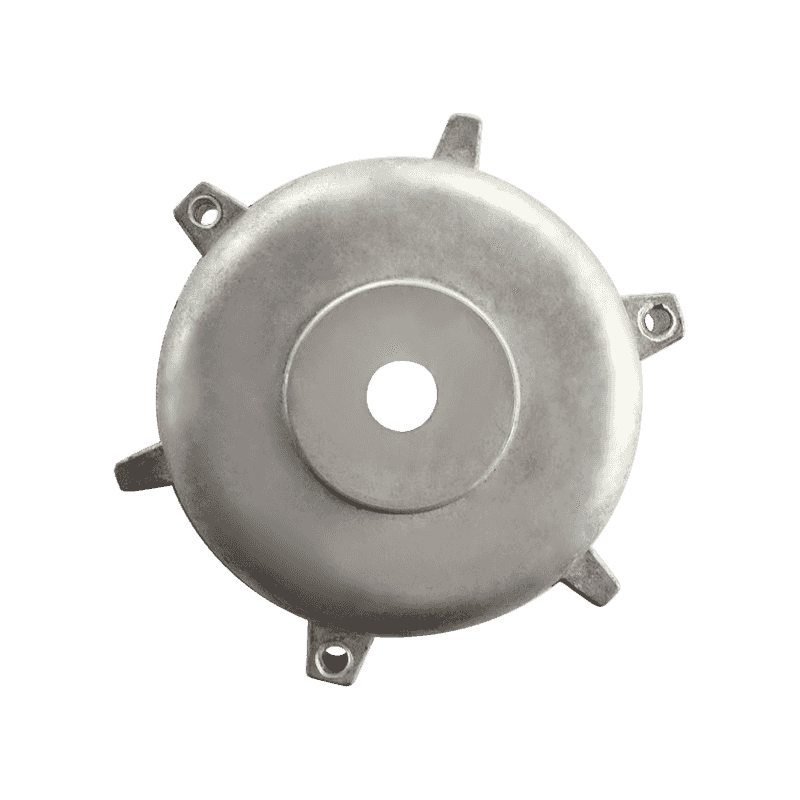

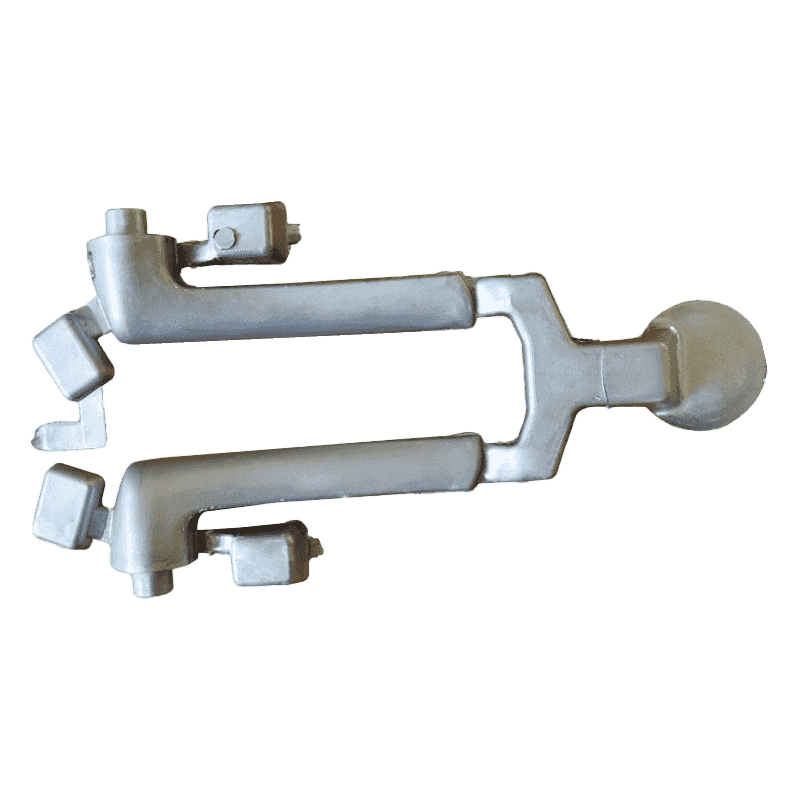

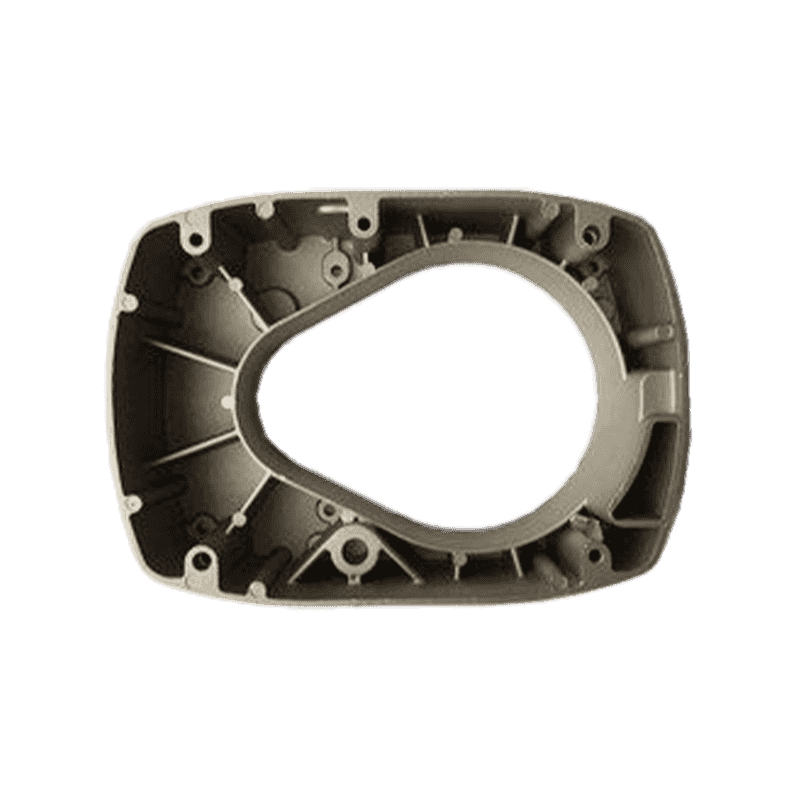

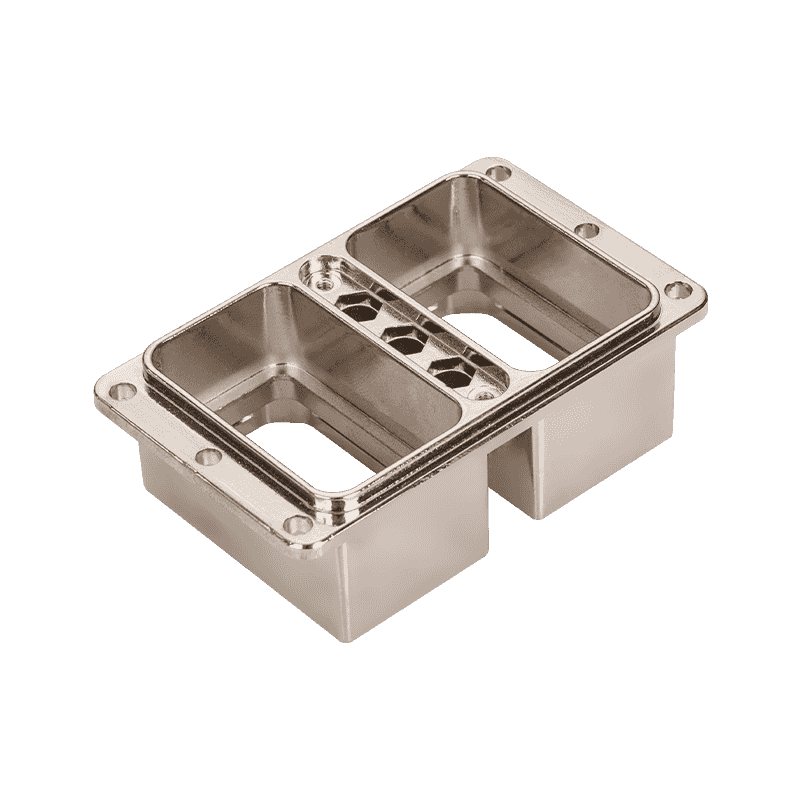

At its core, aluminium alloy die casting is a manufacturing method where molten aluminium is injected into a steel mold (called a die) under high pressure. Once cooled, the shape comes out almost ready to use. For auto parts, this means components like engine brackets, transmission housings, suspension parts, and structural frames can be produced with high precision and consistency.

Why is this so important now?

Because carmakers are under pressure from all sides. Fuel efficiency rules, emissions standards, and the push for electric vehicles mean that every gram counts. Aluminium is lighter than steel, so swapping steel parts for aluminium die castings can reduce vehicle weight and improve energy efficiency. And since the process is highly repeatable, manufacturers can produce large volumes without sacrificing quality.

When is aluminium die casting used in automotive production?

It’s most commonly used in areas where strength and precision matter, but weight savings are also a major concern. You’ll often see aluminium die cast parts in:

- - Engine blocks and cylinder heads

- - Transmission cases

- - Structural supports and brackets

- - Electric vehicle housings and battery frames

Basically, any place where the part needs to be strong, accurate, and lightweight.

How does it work, and why does it fit auto manufacturing so well?

The process is straightforward but powerful. Aluminium is melted, injected into the die, cooled, then ejected. The real magic is in the die design and the process control. With high pressure, the molten metal fills even complex shapes quickly, producing parts with smooth surfaces and tight tolerances. For automakers, that means less machining, fewer defects, and faster production cycles.

Also, the die casting process is scalable. Once the mold is made, you can run it continuously, making it perfect for large production runs typical in the auto industry.

What are the pros and cons?

Let’s be honest: there are tradeoffs.

Pros

First, aluminium is lighter, which helps with fuel efficiency and range (especially for EVs). Second, die casting produces highly consistent parts, which is essential for safety-critical auto components. Third, the surface finish is usually better than other methods, meaning less secondary processing.

Cons

However, die casting requires a big upfront investment. The die itself can be expensive, and designing it correctly is a challenge. Also, aluminium can be more brittle than steel in some cases, so parts must be engineered carefully to avoid cracking or fatigue under stress.

What should manufacturers pay attention to?

If you’re producing aluminium die cast auto parts, there are a few key things to watch:

Material selection and alloy choice

Different aluminium alloys behave differently. The wrong choice can lead to weak spots, poor corrosion resistance, or issues during casting.

Die design and cooling

Good die design ensures the metal fills properly and cools evenly. Uneven cooling can cause warping, internal stresses, or surface defects.

Quality control

Automotive parts need to meet strict standards. Manufacturers must monitor porosity, strength, and surface quality. Using automated inspection systems can help catch issues early.

Supply chain and production stability

Since die casting is a high-volume process, stability matters. Any interruption in material supply, tooling, or equipment can cause big delays.

How manufacturers can stay competitive

Today’s auto market is moving fast. The companies that win are the ones that combine technical strength with flexible production. For aluminium die casting, that means investing in modern machines, skilled die designers, and strict quality systems. It also means staying close to customers to understand what parts they need and how to make them better.

Final thoughts

Aluminium alloy die casting auto parts are not just a manufacturing trend—they’re a real solution to the challenges automakers face today. The shift toward lighter, more efficient vehicles is accelerating, and die casting is one of the most practical ways to meet those demands. For manufacturers, the key is to balance cost, quality, and engineering capability. Get that right, and the future looks pretty bright.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский