How can zinc die casting ensure consistency in mass production?

19-02-2026Understanding Consistency in Zinc Die Casting Production

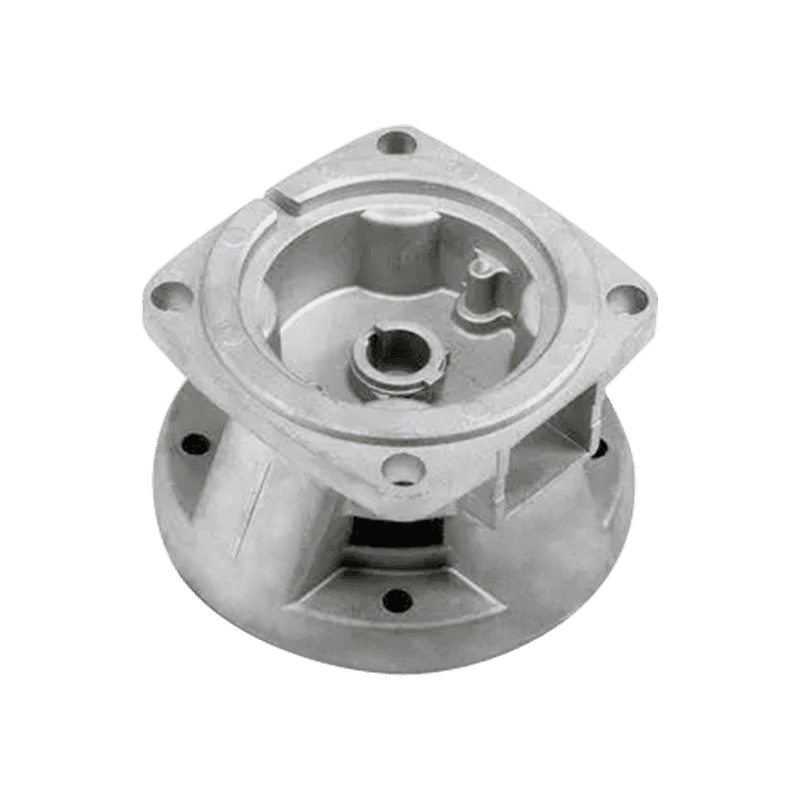

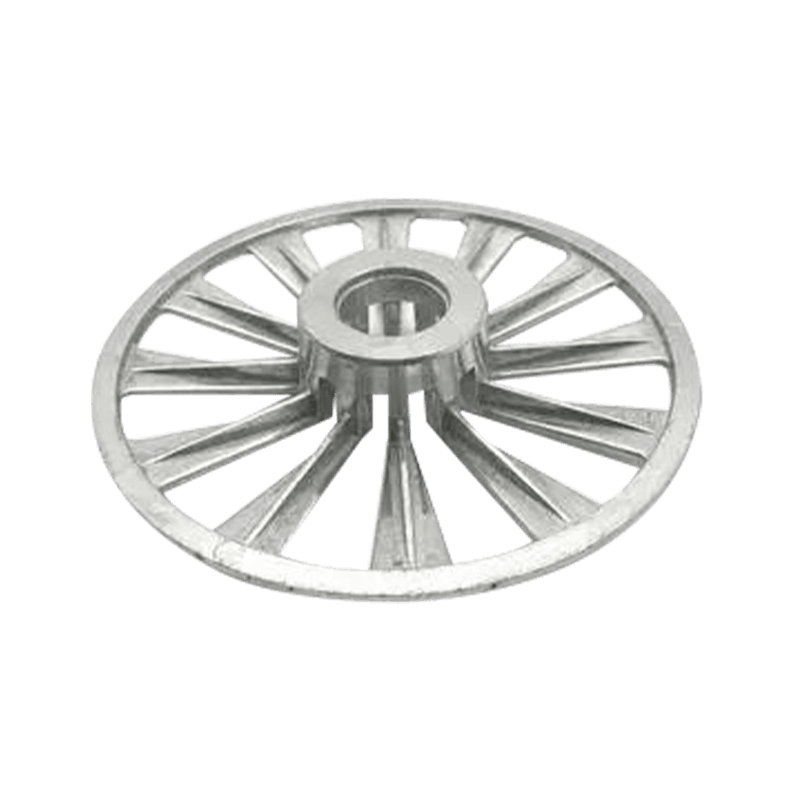

Consistency in mass production refers to the ability to manufacture large quantities of components that maintain uniform dimensions, material properties, appearance, and performance. Zinc die casting is widely used for high-volume manufacturing because its process characteristics support repeatable outcomes. Through controlled tooling, stable material behavior, and automated production systems, zinc die casting creates conditions where consistency can be maintained across extended production cycles.

Role of Zinc Alloy Characteristics in Process Stability

Zinc alloys used in die casting have predictable melting behavior, low viscosity in the molten state, and stable solidification characteristics. These properties allow molten zinc to fill complex mold cavities in a consistent manner during each injection cycle. Because zinc alloys solidify with limited shrinkage compared to some other metals, dimensional variation between parts can be kept within controlled tolerances, which directly supports consistency in mass production.

Precision Tooling and Mold Design

Mold design is a core factor in achieving consistent zinc die cast parts. Steel molds used in zinc die casting are manufactured with high precision, allowing cavities to maintain their shape over many production cycles. Proper gate placement, venting, and cooling channel design ensure that molten zinc flows evenly and solidifies uniformly. A well-designed mold minimizes internal stresses and reduces dimensional variation, supporting repeatable results throughout large production runs.

Mold Longevity and Wear Control

Zinc die casting operates at lower temperatures than aluminum or magnesium die casting, which reduces thermal stress on molds. This contributes to slower mold wear and more stable cavity dimensions over time. With appropriate maintenance and periodic inspection, molds can produce a high number of parts while maintaining consistent geometry. Reduced mold degradation directly supports uniformity across batches produced weeks or months apart.

Automated Injection and Cycle Control

Automation plays a major role in maintaining consistency during mass production. Modern zinc die casting machines control injection speed, pressure, and cycle time with high accuracy. Once optimal parameters are established, these settings can be repeated for every cycle, reducing variability caused by manual operation. Automated systems also help maintain consistent cooling times, which affects part density and surface quality.

Temperature Management During Production

Stable temperature control is essential for consistent zinc die casting. The molten zinc temperature, mold temperature, and ambient production environment are all monitored and regulated. Consistent thermal conditions ensure that the molten metal flows and solidifies in a predictable way. Fluctuations in temperature can lead to differences in surface finish or internal structure, so controlled heating and cooling systems are a key part of consistent mass production.

Process Parameter Standardization

Standardized process parameters are established during initial production trials and validated through testing. These parameters include injection pressure, shot speed, fill time, and cooling duration. Once validated, they are documented and maintained as part of standard operating procedures. This approach ensures that each production shift and each machine follows the same guidelines, reducing variation between parts produced at different times.

Quality Control Integration

Quality control measures are integrated throughout the zinc die casting process rather than applied only at the end. In-process inspections, such as dimensional checks and visual surface evaluations, help identify deviations early. Statistical process control techniques are often used to monitor key dimensions and detect trends that could indicate process drift. Early detection allows corrective actions before inconsistencies affect large quantities of parts.

Material Consistency and Alloy Control

Maintaining consistent alloy composition is essential for uniform mechanical and physical properties. Zinc die casting operations typically source alloy ingots that meet standardized chemical composition requirements. Incoming material is verified, and melt composition is monitored during production. Consistent alloy chemistry helps ensure stable flow behavior, solidification patterns, and mechanical characteristics across all produced parts.

Controlled Feeding and Melting Systems

Modern zinc die casting facilities use controlled melting and feeding systems to maintain uniform metal quality. Automated furnaces regulate melt temperature and reduce contamination. By maintaining a steady supply of molten zinc with consistent properties, variations caused by oxidation, inclusions, or temperature differences can be minimized, supporting stable production output.

Operator Training and Process Discipline

Even in automated environments, trained operators play a vital role in maintaining consistency. Operators are responsible for monitoring machine performance, identifying abnormal conditions, and performing routine checks. Consistent training programs ensure that personnel follow established procedures and respond appropriately to deviations, reducing the risk of variation caused by human factors.

Post-Processing Consistency

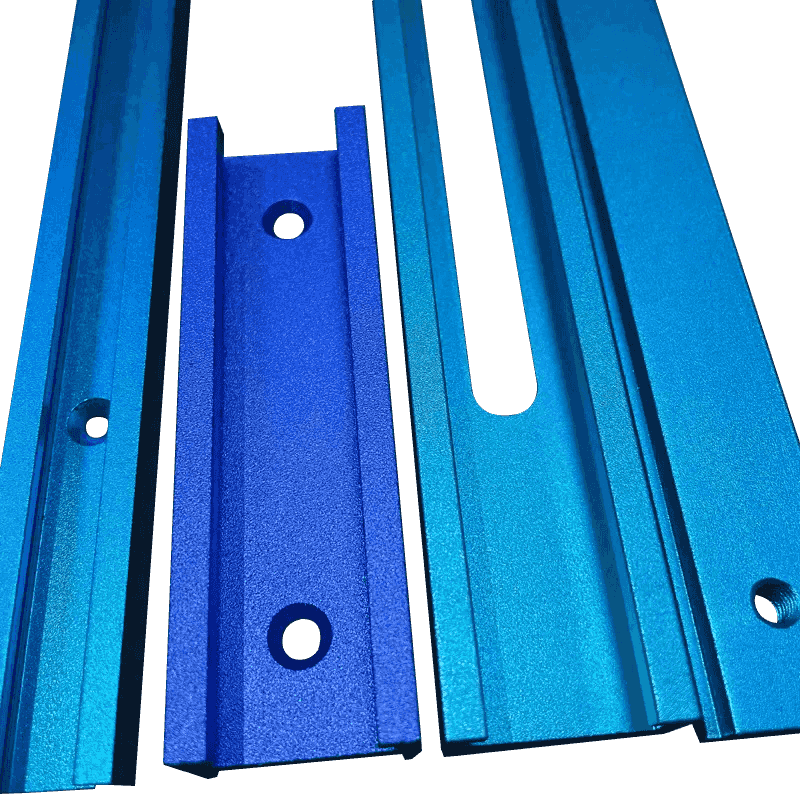

After casting, zinc components may undergo trimming, machining, or surface finishing. Consistency in these post-processing steps is essential to maintain uniform final dimensions and appearance. Automated trimming tools, standardized machining programs, and controlled surface treatment processes help ensure that each part meets the same specifications regardless of production volume.

Dimensional Accuracy and Repeatability

Zinc die casting is known for its ability to produce parts with close dimensional tolerances. This repeatability is achieved through stable molds, controlled injection parameters, and predictable material behavior. Dimensional accuracy reduces the need for secondary machining and supports interchangeability of parts in assembly processes, which is a key requirement in mass production environments.

Surface Finish Uniformity

Surface appearance is often a visible indicator of production consistency. Zinc die casting can produce smooth surfaces directly from the mold when parameters are controlled. Consistent mold surface condition, controlled fill speed, and stable temperature all contribute to uniform surface finish across large production batches. This is especially important for components used in consumer products or visible assemblies.

Process Documentation and Traceability

Documenting process parameters, material batches, and inspection results supports long-term consistency. Traceability allows manufacturers to link finished parts to specific production conditions. When variations occur, historical data helps identify root causes and implement corrective measures, preventing repeated inconsistencies in future production runs.

Comparison of Factors Influencing Consistency

| Factor | Contribution to Consistency | Control Method |

| Mold Design | Stable geometry and repeatable filling | Precision machining and maintenance |

| Alloy Composition | Uniform mechanical and flow properties | Standardized material sourcing |

| Injection Parameters | Repeatable part formation | Automated machine control |

| Quality Monitoring | Early detection of variation | In-process inspection systems |

Scalability of Zinc Die Casting Operations

Zinc die casting is well suited for scaling production from initial batches to very high volumes. Once molds and parameters are established, increasing output typically involves extending machine runtime or adding identical production cells. This scalability allows manufacturers to maintain consistent part quality while meeting growing demand without redesigning the process.

Integration with Lean Manufacturing Practices

Lean manufacturing principles align well with zinc die casting processes. Reduced scrap rates, stable cycle times, and predictable output support efficient production planning. Consistency in part quality reduces rework and inspection burdens, contributing to smoother material flow and more reliable delivery schedules in mass production environments.

Long-Term Production Stability

Over extended production periods, maintaining consistency requires ongoing monitoring and adjustment. Regular mold inspections, calibration of machines, and review of quality data help ensure that the process remains within defined limits. Zinc die casting’s inherent process stability makes it suitable for long-term mass production when supported by disciplined process management.

Practical Outcomes of Consistent Zinc Die Casting

Consistent zinc die casting enables manufacturers to supply interchangeable parts, reduce assembly issues, and meet customer specifications reliably. The combination of material properties, precise tooling, automation, and quality control creates a manufacturing environment where uniformity can be maintained across large production volumes. This reliability is a key reason zinc die casting is widely adopted for components used in automotive, electronics, hardware, and consumer goods industries.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский