Is zinc die casting suitable for producing parts with complex shapes?

22-01-2026Introduction to Zinc Die Casting

Zinc die casting is a widely used manufacturing process for producing parts that require high precision, complex shapes, and strength. It involves forcing molten zinc alloy into a mold under high pressure to create detailed and consistent parts. Zinc die casting is often chosen for applications in various industries, including automotive, electronics, and consumer goods, due to its combination of cost-effectiveness, ease of production, and the ability to produce components with intricate designs. However, the suitability of zinc die casting for producing parts with complex shapes is an important consideration that requires understanding the advantages and limitations of the process.

Understanding Zinc Die Casting Process

The zinc die casting process begins by melting zinc alloy in a furnace and then injecting it into a mold under high pressure. The mold, typically made from hardened steel, is carefully designed to allow the molten metal to flow smoothly into the cavities and fill every detail of the mold. Once the metal cools and solidifies, the mold is opened, and the cast part is removed. The process is highly efficient, offering fast production cycles and the ability to produce parts with excellent dimensional accuracy and surface finish.

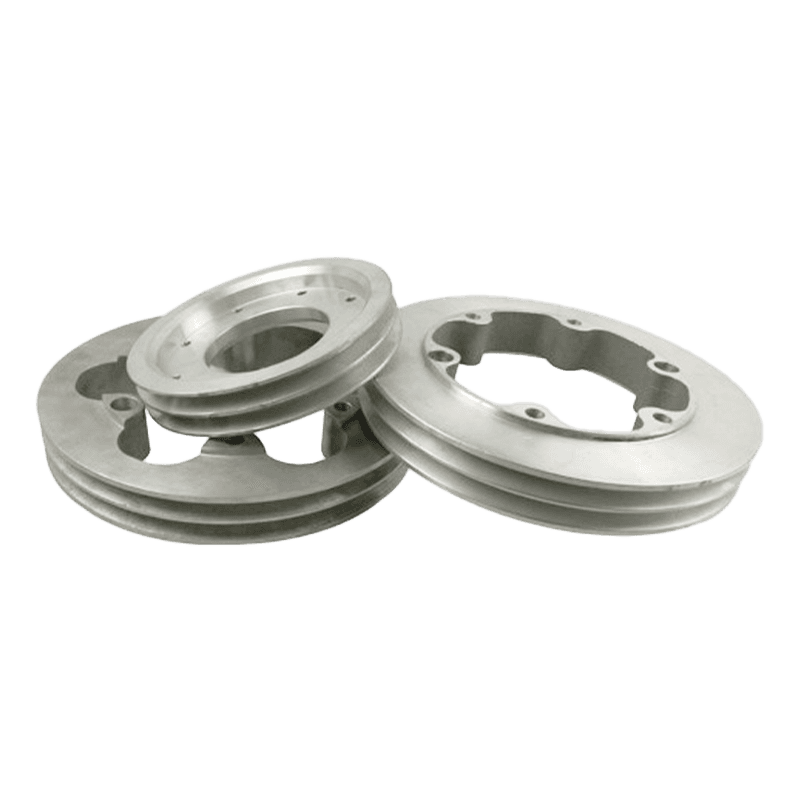

Zinc die casting is particularly advantageous when producing parts in large quantities because it allows for high-speed production with minimal material waste. The process can produce parts with thin walls, tight tolerances, and fine details, making it suitable for creating components with complex geometries. Additionally, zinc alloys used in die casting offer good mechanical properties, including strength, durability, and corrosion resistance, which contribute to the quality of the finished parts.

Capabilities of Zinc Die Casting for Complex Shapes

One of the key reasons why zinc die casting is considered suitable for producing complex shapes is its ability to replicate intricate designs with high precision. The high-pressure injection process ensures that the molten zinc fills every detail of the mold, even for parts with fine features such as undercuts, thin walls, and intricate patterns. This capability allows designers to create components that would otherwise be challenging to manufacture using traditional methods like machining or casting.

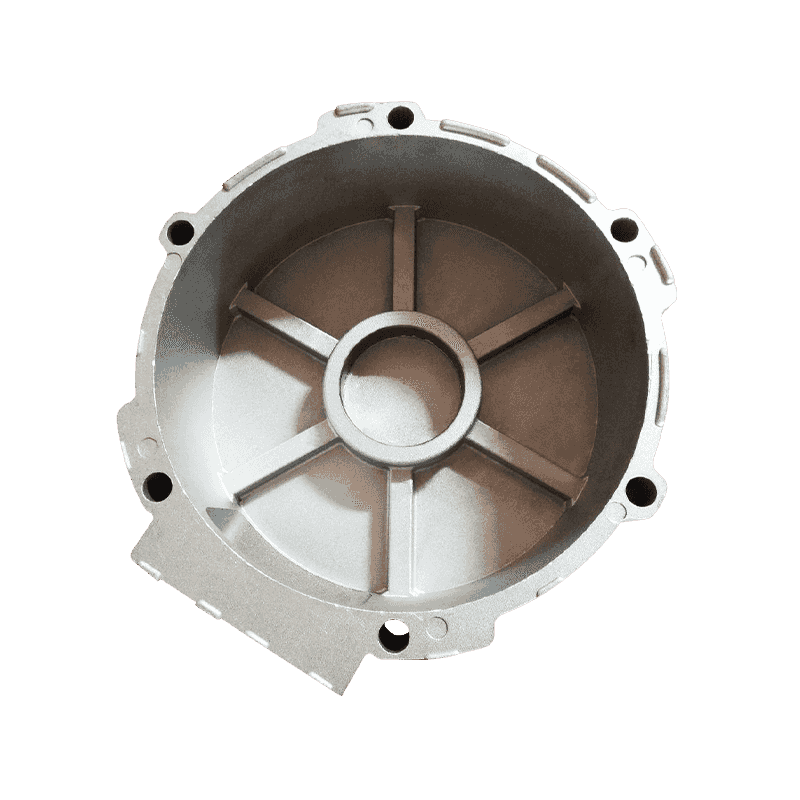

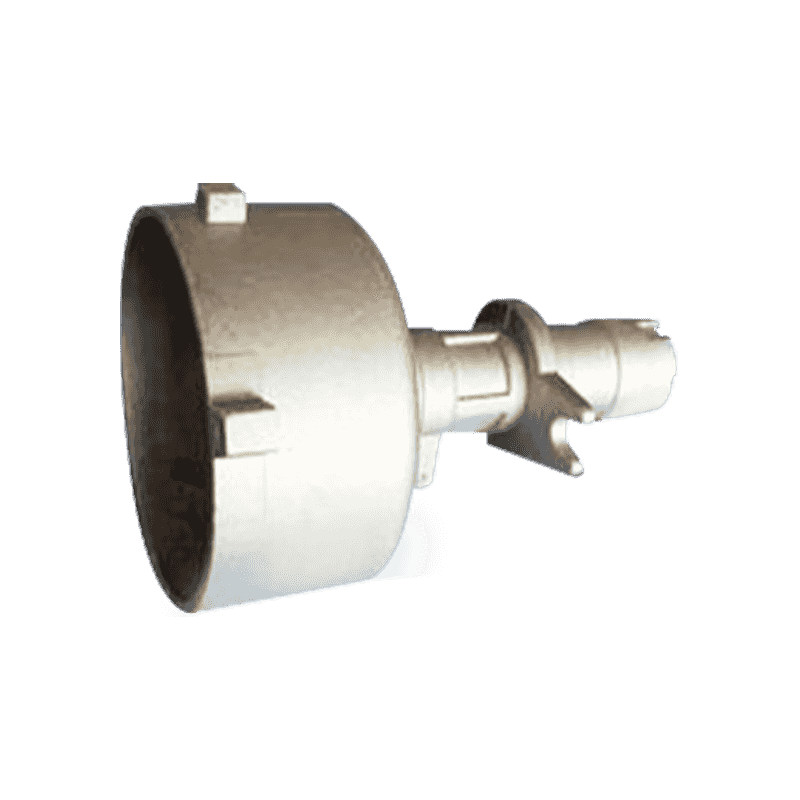

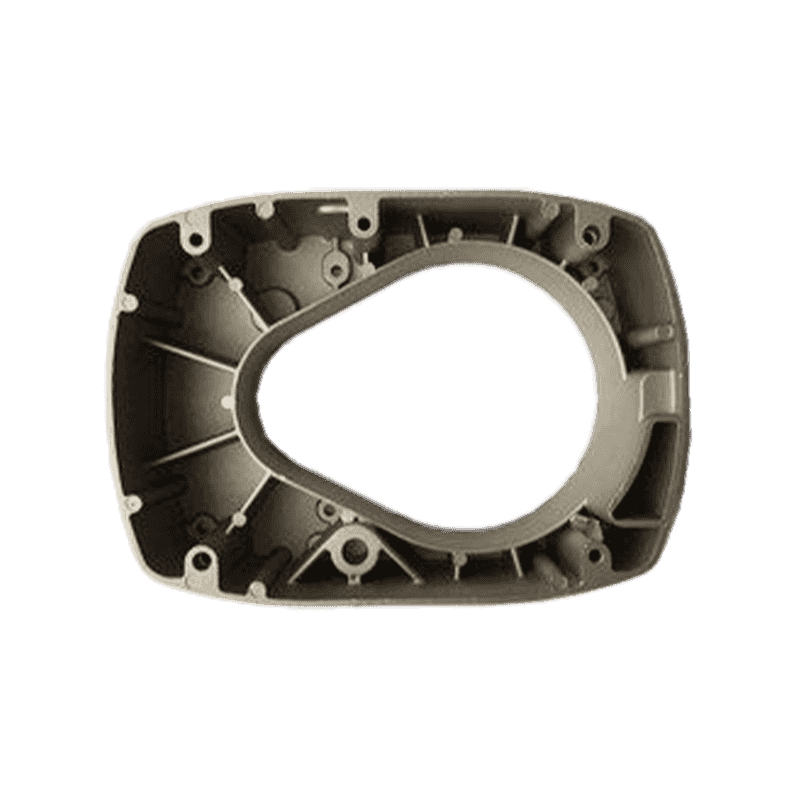

For example, zinc die casting can produce parts with complex internal features, such as channels or cavities, which are often required in automotive or electronic components. The ability to produce parts with undercuts, which are features that cannot be easily removed from a mold, is another significant advantage of the zinc die casting process. This is made possible by the design of the mold, which can include moving cores or slides that allow for the creation of undercuts without compromising the integrity of the mold.

Additionally, the ability to create thin-walled parts is one of the significant strengths of zinc die casting. Parts with thin walls can be produced with high precision, allowing for the production of lightweight and efficient components with complex geometries. This is especially important in industries like automotive manufacturing, where reducing the weight of parts without compromising strength is a priority.

Limitations in Producing Complex Shapes

While zinc die casting is well-suited for many complex shapes, there are certain limitations to consider when evaluating its suitability for producing intricate parts. The main limitation is the complexity of the mold design and the cost associated with it. The mold used in die casting is typically made from hardened steel, which can be expensive to manufacture, particularly for parts with intricate designs. The design of the mold needs to be carefully planned to ensure that the molten metal flows properly into all parts of the mold and that the part can be easily removed after cooling.

Another consideration is the need for precise mold design to accommodate features such as undercuts or holes. While moving cores and slides can help achieve these features, their inclusion can increase the complexity and cost of the mold. Additionally, the more complex the mold design, the more challenging it becomes to maintain tight tolerances and ensure the accuracy of the finished parts. In some cases, it may be necessary to add additional post-processing steps, such as machining or polishing, to achieve the desired surface finish or dimensional accuracy.

Furthermore, zinc die casting is generally not well-suited for parts with very deep or highly complex internal cavities. The flow of molten zinc can become difficult to control when filling intricate, deep sections of the mold, which may result in incomplete fills or voids within the part. In such cases, alternative manufacturing methods like injection molding or plastic casting might be more suitable, as they can better accommodate more complex internal geometries.

Material Considerations for Complex Parts

The material used in zinc die casting also plays a crucial role in determining whether it is suitable for producing complex shapes. Zinc alloys, such as Zamak, are commonly used in die casting due to their excellent castability, strength, and corrosion resistance. These alloys can be molded into intricate shapes with high precision, making them ideal for producing complex components for various applications.

However, the mechanical properties of zinc alloys are not as strong as those of other metals, such as aluminum or steel. While zinc die casting parts are durable and resistant to corrosion, they may not be suitable for applications that require high strength or resistance to extreme conditions, such as high temperatures or heavy mechanical loads. When designing complex parts, it is essential to consider the material properties to ensure that the finished part will meet the necessary performance requirements. In some cases, the use of zinc die casting may be limited by the need for higher strength materials, in which case other casting processes or materials may be more appropriate.

Design Flexibility in Zinc Die Casting

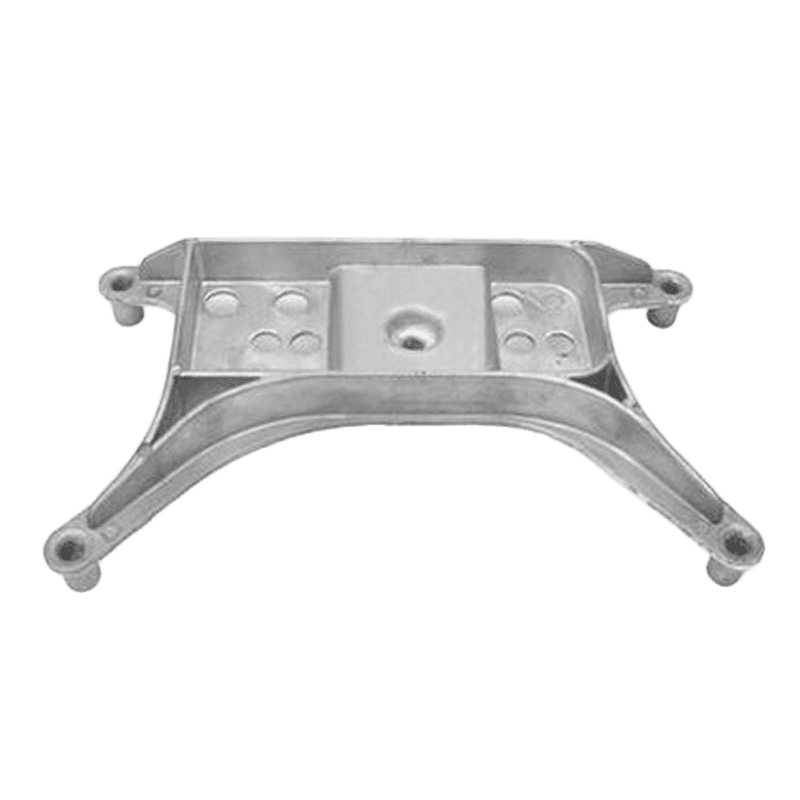

Zinc die casting offers significant design flexibility, which is another reason why it is suitable for producing parts with complex shapes. The process allows for a high degree of precision, making it possible to create parts with intricate surface details, textures, and features that would be difficult or time-consuming to achieve with other manufacturing methods. Designers can incorporate complex geometries, such as ribs, bosses, and holes, into their designs without worrying about significant increases in production time or costs.

The ability to produce parts with thin walls and tight tolerances also adds to the design flexibility of zinc die casting. Thin-walled parts can be produced without sacrificing strength or stability, making them ideal for lightweight applications where space and weight are a concern. This is particularly important in industries like automotive manufacturing, where reducing the weight of components can improve fuel efficiency and overall performance.

Additionally, zinc die casting allows for the integration of multiple features into a single part. In many cases, parts that would traditionally require multiple manufacturing steps or assembly processes can be created in one step, reducing overall production costs and lead times. This design flexibility is one of the reasons why zinc die casting is widely used for producing complex parts in industries such as automotive, electronics, and consumer goods.

Post-Processing and Finishing for Complex Parts

Once the zinc die casting process is completed, it is often necessary to perform post-processing and finishing operations to achieve the desired surface quality, accuracy, and performance of the part. Common post-processing techniques include machining, polishing, surface treatments, and coating applications. These processes are particularly important for parts with complex shapes, as they can help address any imperfections or variations in the casting that may have occurred during the manufacturing process.

Machining is commonly used to remove any excess material, such as flash or burrs, from the part and to achieve tighter tolerances. This is particularly important for parts with intricate features or fine details that require precise dimensions. Polishing and surface treatments, such as powder coating or plating, can also be applied to improve the appearance and corrosion resistance of the part. These finishing operations allow for greater design flexibility, as parts can be customized to meet aesthetic and functional requirements.

Applications of Zinc Die Casting for Complex Parts

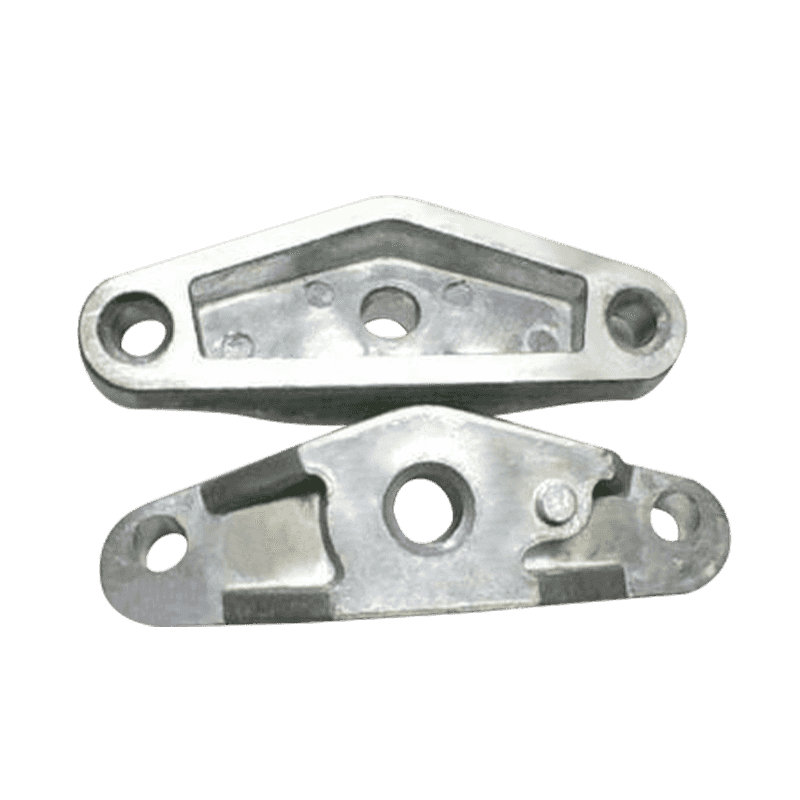

Despite its limitations, zinc die casting remains a popular choice for producing parts with complex shapes in various industries. The automotive industry, for example, makes extensive use of zinc die casting to produce components such as housing units, brackets, and connectors, which require both strength and intricate design features. Electronics manufacturers also rely on zinc die casting for creating parts like heat sinks, enclosures, and electrical connectors, which often require complex geometries and high precision.

In the consumer goods industry, zinc die casting is used to produce components such as door hardware, decorative items, and appliance parts. The ability to create complex shapes at a relatively low cost makes zinc die casting an ideal choice for these applications, where both aesthetics and functionality are important. Overall, zinc die casting's ability to produce high-quality parts with intricate shapes at a competitive price makes it suitable for a wide range of industries.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский