Can aluminum alloy die-cast auto parts replace traditional steel components to reduce weight?

08-01-2026Introduction to Aluminum Alloy Die-Casting in Automotive Applications

Aluminum alloy die-casting has become a widely used manufacturing process in the automotive industry due to its ability to produce complex shapes with high dimensional accuracy. The automotive sector is increasingly focused on reducing vehicle weight to improve fuel efficiency, reduce emissions, and enhance overall performance. Replacing traditional steel components with aluminum alloy die-cast parts is seen as a viable strategy to achieve these objectives, given aluminum's lower density and adequate mechanical properties for many applications.

Material Properties of Aluminum Alloys

Aluminum alloys offer a combination of light weight, corrosion resistance, and reasonable mechanical strength, making them suitable for a variety of automotive components. The density of aluminum alloys is roughly one-third that of steel, which can significantly reduce component weight when used in place of steel. Aluminum also exhibits good thermal and electrical conductivity, which can be advantageous for engine components, heat exchangers, and electronic housings. The choice of alloy, such as Al-Si-Cu or Al-Mg-Si variants, impacts tensile strength, elongation, and fatigue resistance, and these properties determine which steel components can be effectively replaced.

Die-Casting Process and Its Influence on Component Performance

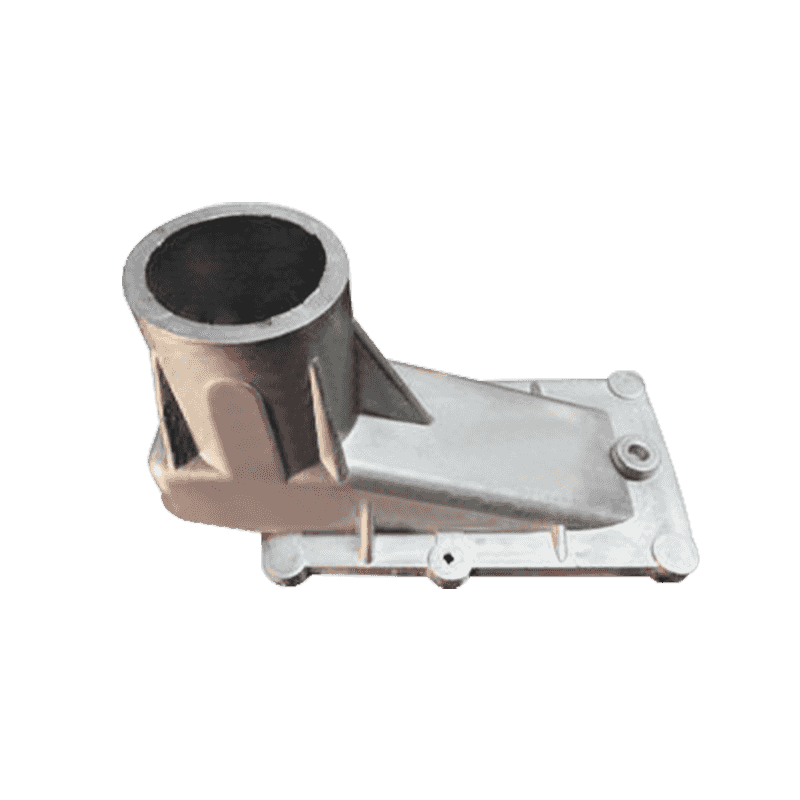

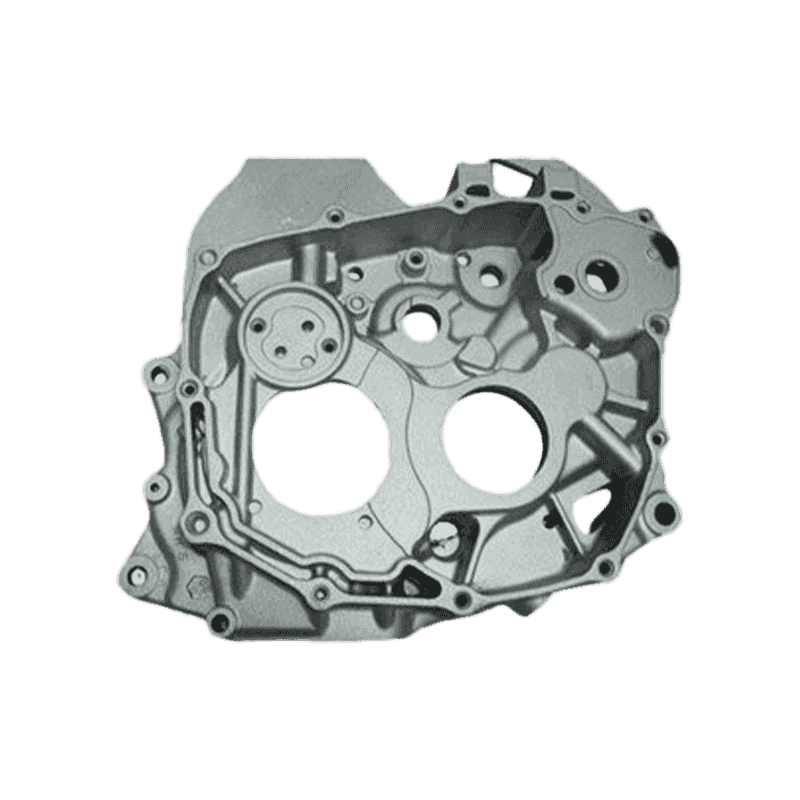

The die-casting process involves injecting molten aluminum alloy into a steel mold under high pressure. This process allows for the creation of intricate geometries that are often difficult or costly to achieve with steel stamping or machining. Die-casting can also integrate multiple functional features into a single component, such as mounting points, ribs, and internal channels. The rapid solidification of the aluminum alloy during die-casting results in a fine microstructure that contributes to mechanical strength, while careful process control reduces porosity and enhances dimensional stability.

Weight Reduction Potential

Replacing steel parts with aluminum alloy die-cast components offers substantial weight reduction opportunities. A typical steel component can be replaced with an aluminum counterpart weighing approximately 40–60% less, depending on design requirements and loading conditions. This reduction in weight improves fuel economy and electric vehicle range while reducing overall vehicle mass. Additionally, lighter components can decrease suspension and braking loads, contributing to improved handling and performance.

Comparison of Mechanical Strength with Steel

While aluminum alloys have a lower density than steel, their mechanical strength can be sufficient for many automotive applications. Tensile strength of die-cast aluminum alloys can range from 200 to 400 MPa, which is lower than most structural steels but adequate for non-critical load-bearing parts such as engine housings, transmission cases, brackets, and housings. Design adjustments, such as increased wall thickness or reinforced ribs, can compensate for differences in strength. In critical applications, hybrid structures combining aluminum with steel or other reinforcements can achieve required performance while maintaining weight savings.

| Property | Aluminum Alloy Die-Cast | Steel |

|---|---|---|

| Density (g/cm³) | 2.7 | 7.8 |

| Tensile Strength (MPa) | 200–400 | 400–600 |

| Corrosion Resistance | High | Moderate, requires coating |

| Manufacturing Flexibility | Complex geometries, integrated features | Limited by stamping or machining |

Corrosion Resistance Advantages

Aluminum alloys form a natural oxide layer that provides resistance to corrosion, whereas steel components often require coatings, paints, or galvanization to achieve comparable protection. This characteristic is particularly beneficial in areas exposed to moisture, road salts, or chemical agents. Reduced corrosion risk contributes to longer service life and lower maintenance requirements for aluminum die-cast components.

Thermal Conductivity and Heat Management

Aluminum alloys possess higher thermal conductivity than steel, which can be advantageous for engine and transmission components, heat exchangers, and battery housings in electric vehicles. Improved heat dissipation helps maintain stable operating temperatures, enhances component performance, and may allow for more compact designs. Thermal properties must be considered in the design phase to balance strength and heat management requirements.

Manufacturing Efficiency and Cost Considerations

Die-casting of aluminum alloys enables high-volume production with consistent quality. Molds can be reused for thousands of cycles, and the integration of multiple features reduces the need for assembly and welding. Although the initial tooling cost is higher than traditional steel stamping, long-term production efficiency and material savings can offset these expenses. Additionally, reduced weight contributes indirectly to lower fuel consumption and operational costs.

Design Adaptations for Aluminum Replacement

Switching from steel to aluminum die-cast parts often requires redesigning the component to account for differences in strength, stiffness, and fatigue behavior. Engineers may increase cross-sectional areas, add reinforcing ribs, or adjust joint locations to maintain structural integrity. Finite element analysis and computational modeling are commonly used to predict mechanical behavior and ensure that aluminum components meet safety and performance standards.

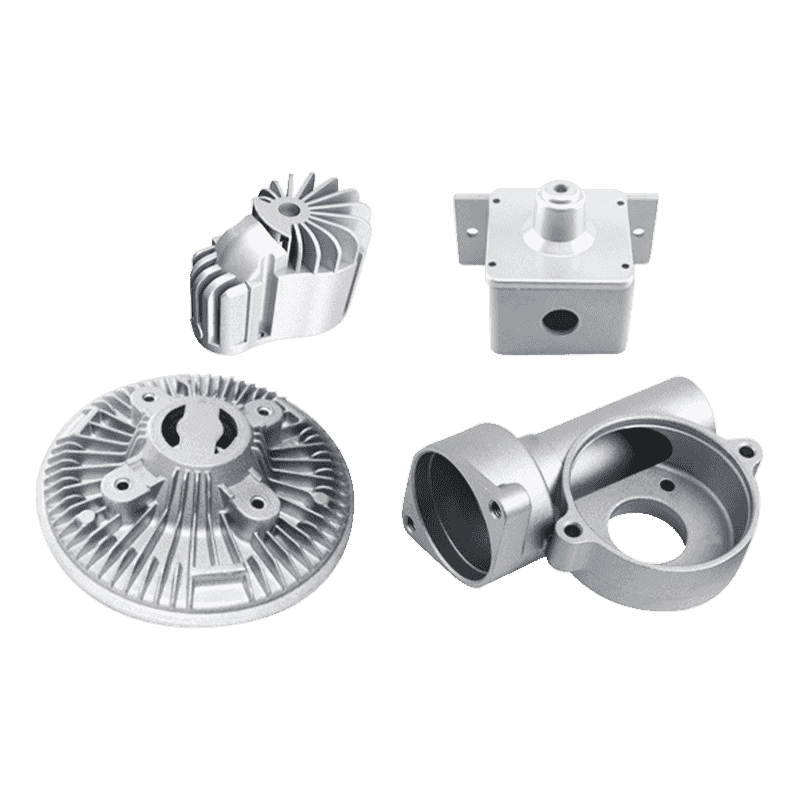

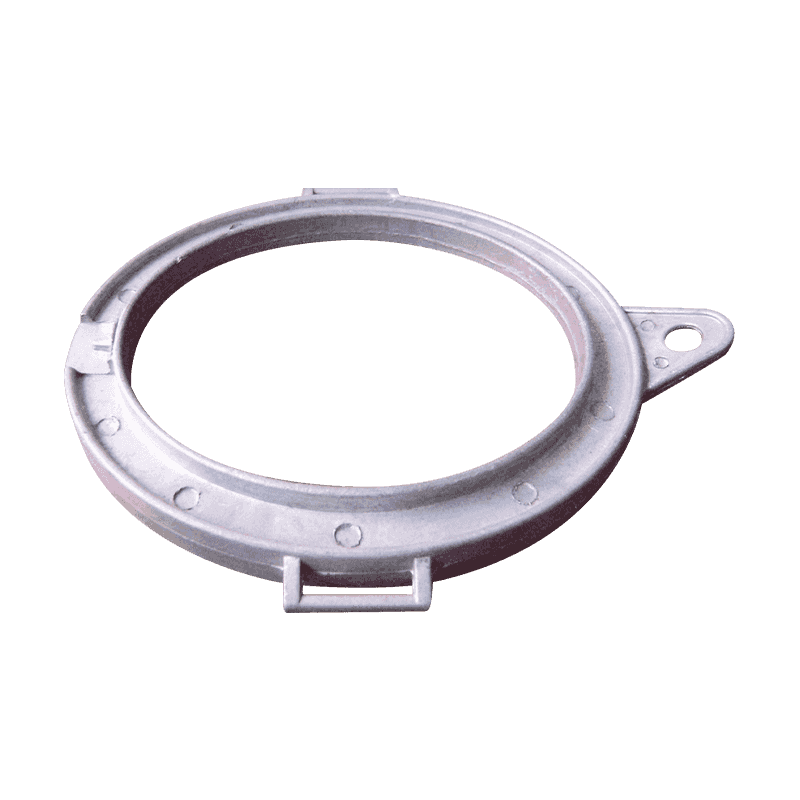

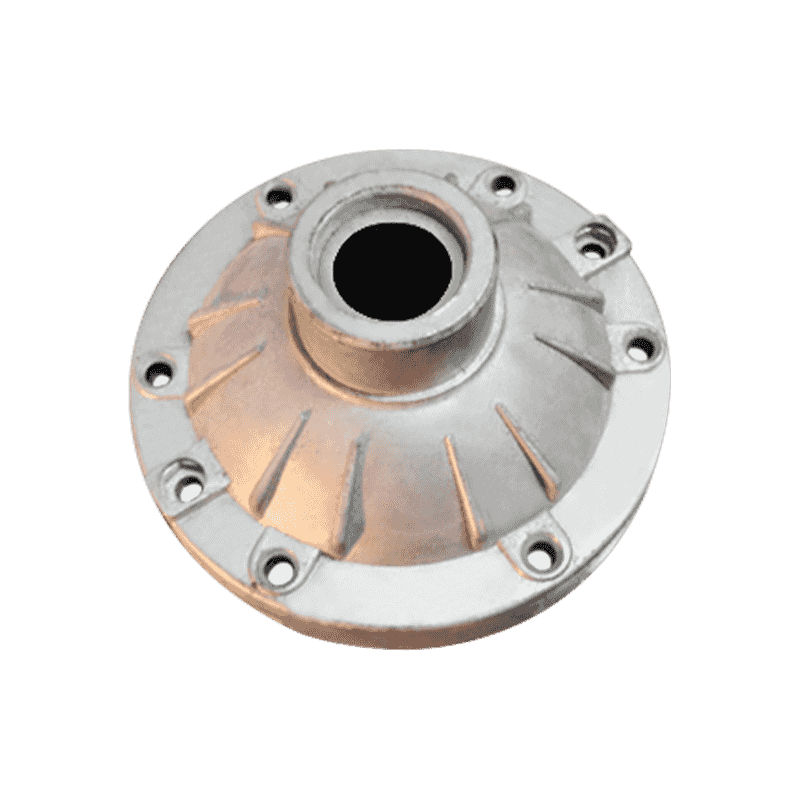

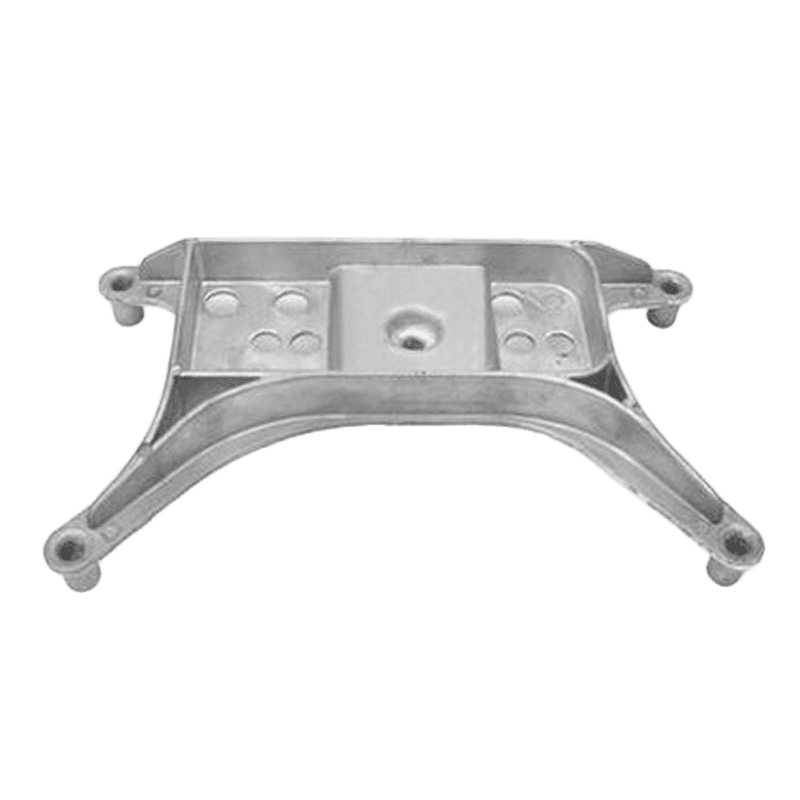

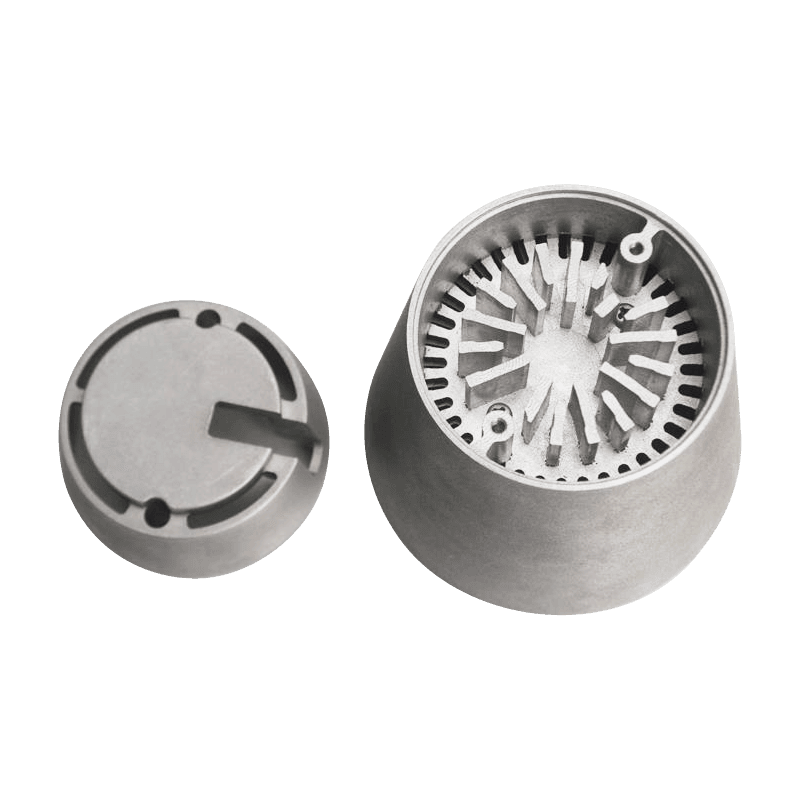

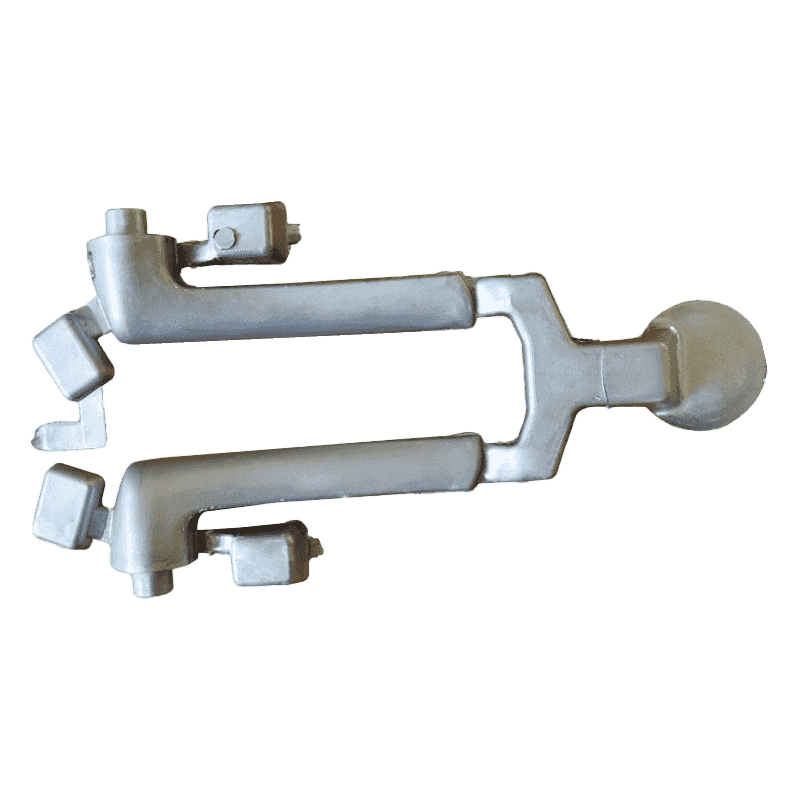

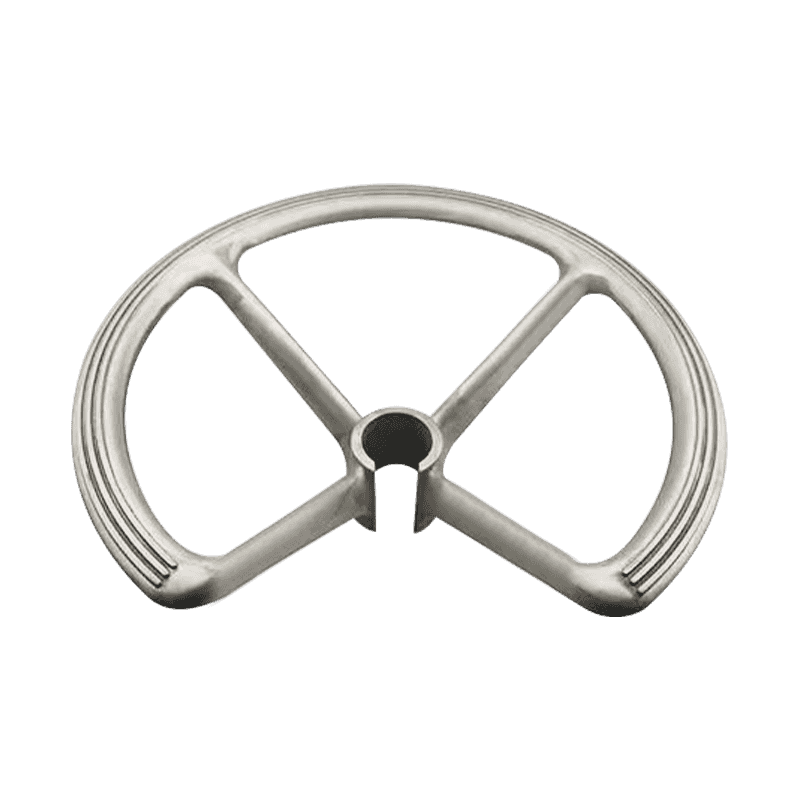

Applications in Automotive Components

Aluminum die-cast parts are widely used in various areas of modern vehicles. Engine blocks, transmission housings, suspension brackets, steering knuckles, and battery enclosures are common examples. Replacing steel components in these applications can achieve significant weight reduction without compromising functionality. Some vehicles also employ mixed-material designs, combining aluminum die-cast parts with steel reinforcements where higher strength is needed.

Environmental and Energy Considerations

Reducing vehicle weight with aluminum die-cast components contributes to lower fuel consumption in internal combustion vehicles and extended range in electric vehicles. Additionally, aluminum can be recycled effectively, which aligns with sustainability goals. The environmental impact of production is mitigated when recycled aluminum is used, and reduced vehicle weight decreases emissions over the vehicle's operational life.

Limitations and Challenges

While aluminum alloy die-cast parts offer weight savings, limitations exist in high-stress applications where steel's higher strength may be necessary. Fatigue resistance and impact performance may be lower for aluminum, requiring careful design and material selection. Joining methods, such as welding or bolting, must also account for differences in thermal expansion and galvanic corrosion when combined with steel components. Proper design and engineering strategies are critical to overcoming these challenges.

Future Trends in Aluminum Die-Cast Automotive Parts

Advancements in die-casting technology, including high-pressure die casting and large-scale or integrated castings, continue to expand the potential applications of aluminum alloys. Improved alloys, enhanced mold technologies, and computer-aided design methods allow for more structural parts to be replaced with aluminum while maintaining safety and performance standards. The automotive industry is expected to increasingly adopt aluminum die-cast components as part of broader lightweighting strategies, particularly for electric and hybrid vehicles.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский