How to check the quality of aluminum die casting?

01-10-2025Visual Inspection Methods

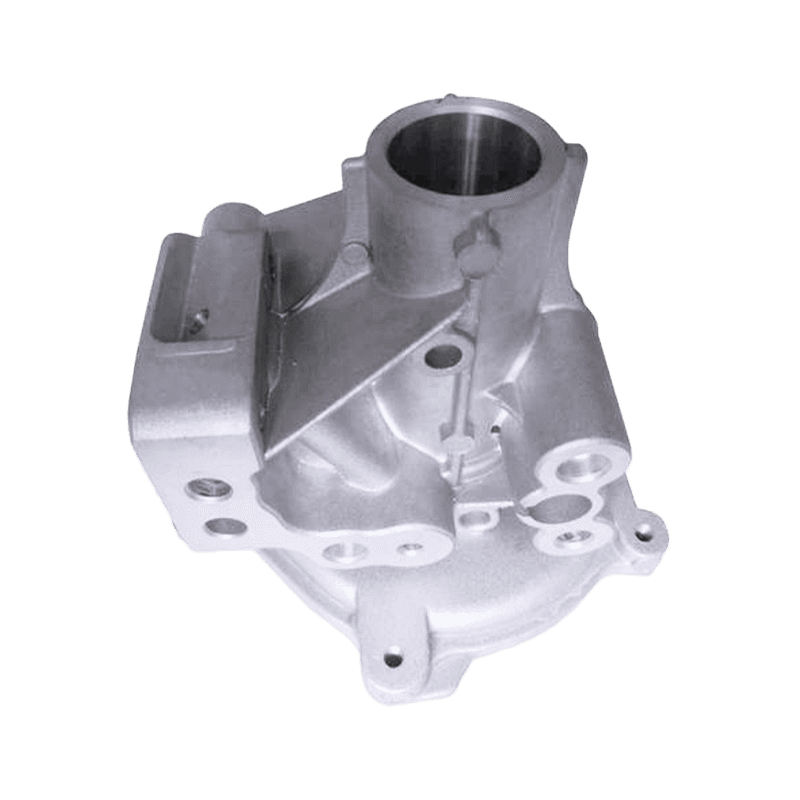

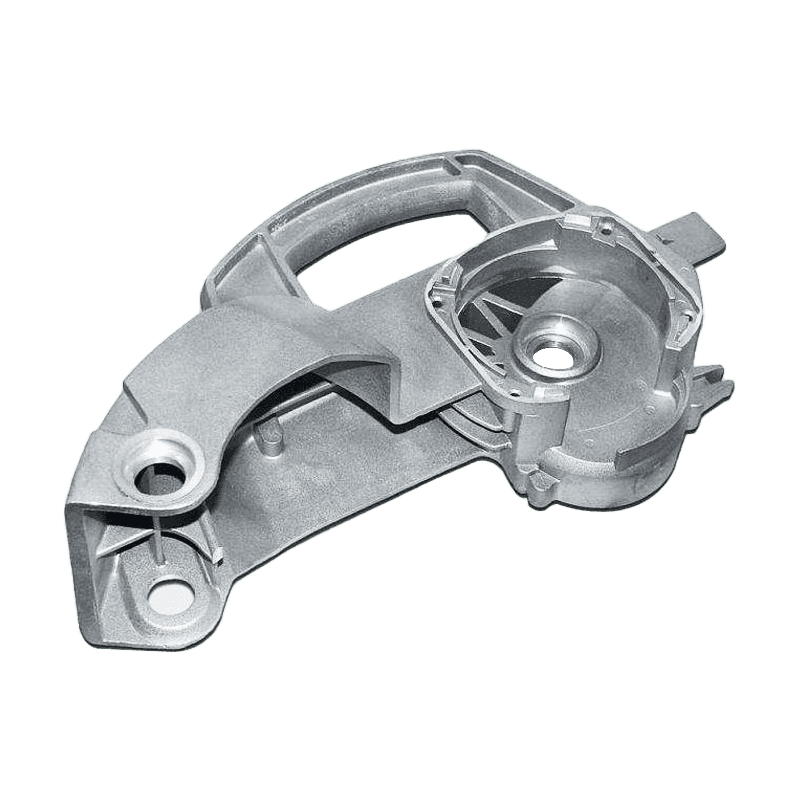

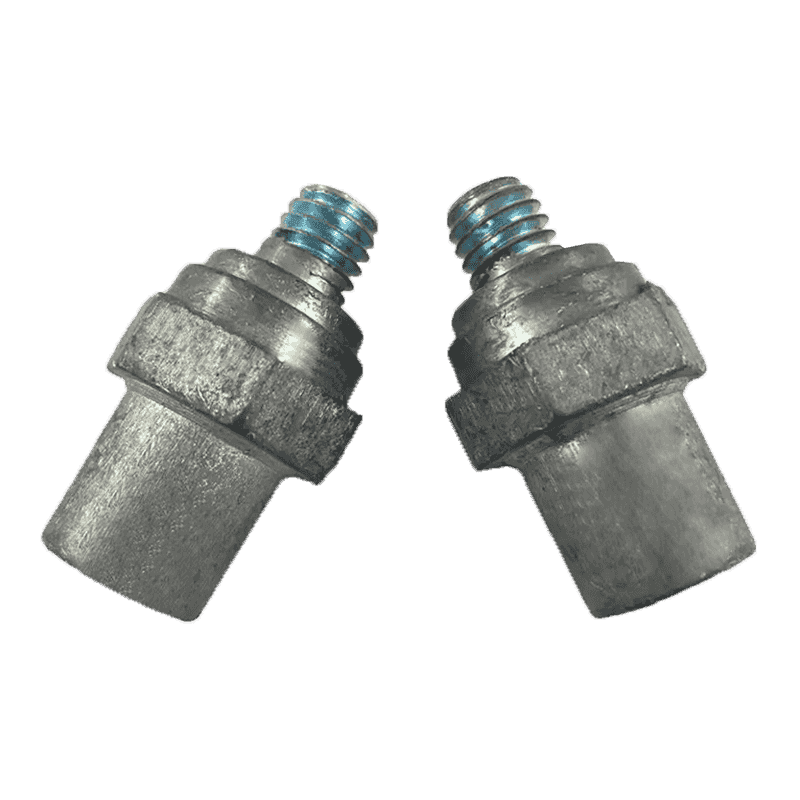

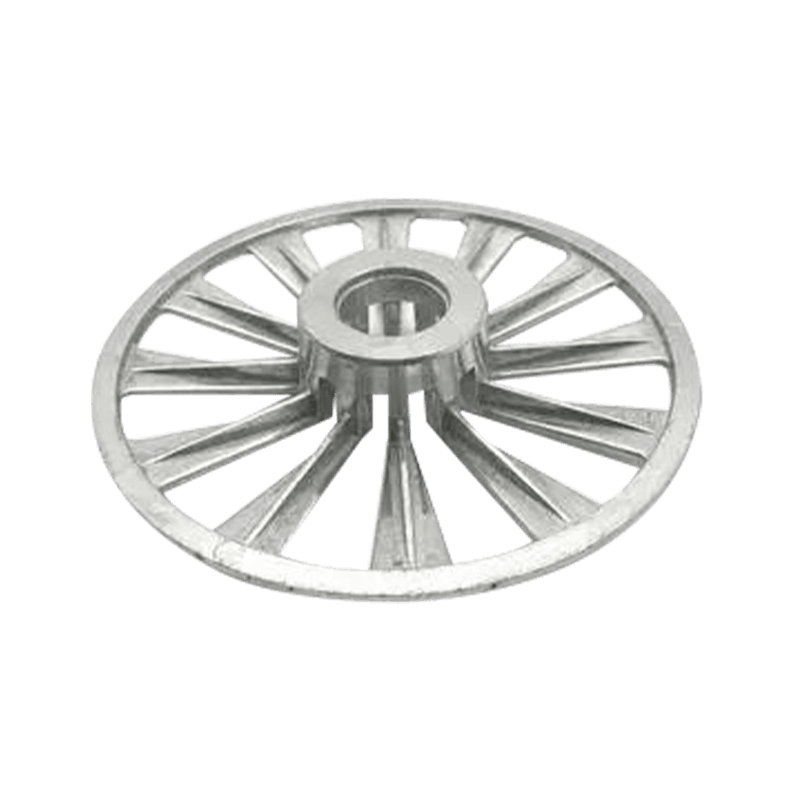

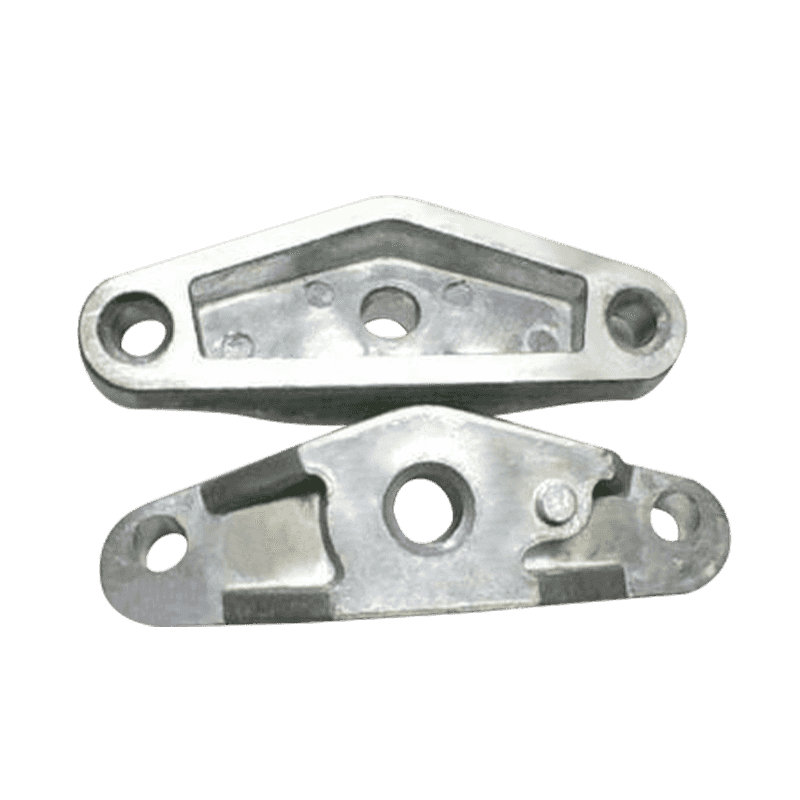

Visual examination serves as the first line of quality assessment for aluminum die castings. Inspectors look for surface defects such as cracks, porosity, cold shuts, or flow marks that may indicate production issues. Proper lighting conditions and magnification tools help identify subtle imperfections that could affect performance. The aluminum's silvery white appearance should be uniform without discoloration or unusual texture variations that might suggest contamination or improper cooling.

Dimensional Accuracy Verification

Precision measurement tools including calipers, micrometers, and coordinate measuring machines (CMM) verify that castings meet specified dimensional tolerances. Critical features like mating surfaces, bore diameters, and wall thicknesses require particular attention. Digital measurement systems can compare parts against CAD models to detect even minor deviations that might impact assembly or function.

X-Ray Computed Tomography Scanning

Advanced non-destructive testing methods like X-ray CT scanning reveal internal defects invisible to surface inspection. This technology clearly distinguishes between aluminum material and voids or inclusions, accurately measuring pore sizes and distributions. The technique reduces image deterioration from Compton scattering and beam hardening effects, providing clear visualization of internal structures without damaging the casting.

Pressure Testing for Porosity

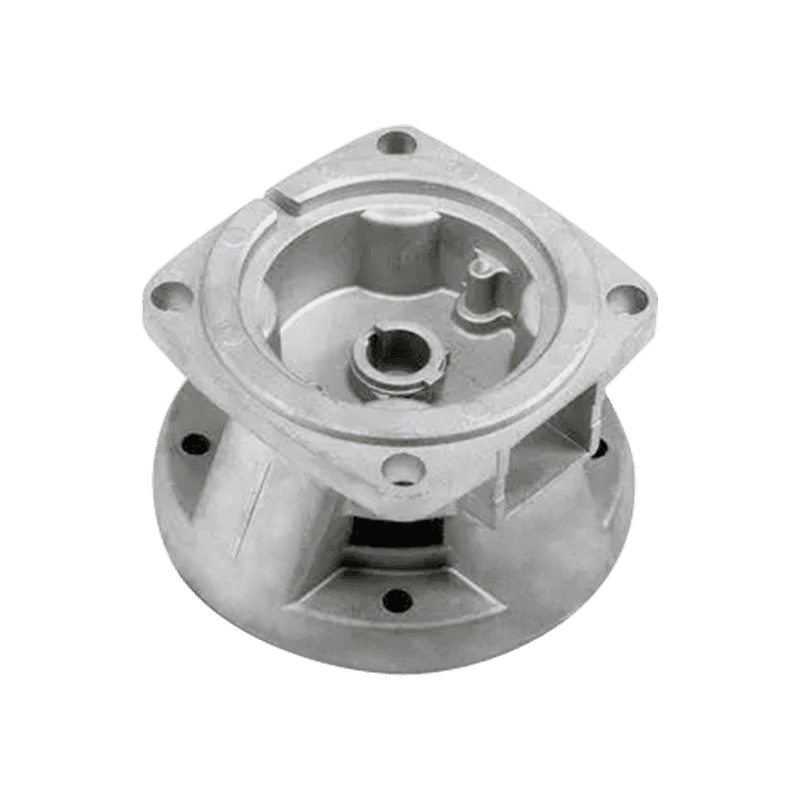

Air pressure tests evaluate casting integrity by measuring gas flow through potential microporosity. The pressure difference across the casting and resulting flow rate calculations can estimate average pore diameters. This method helps identify leak paths that might compromise pressure-tight applications, with results correlating well with actual void dimensions measured through other techniques.

Metallographic Examination

Microstructural analysis through sample preparation and microscopy reveals grain structure, phase distribution, and potential defects. Proper sectioning, mounting, grinding, and polishing create examination-ready surfaces. Etching highlights microstructural features that indicate casting quality, including dendrite arm spacing, porosity distribution, and the presence of intermetallic compounds that could affect mechanical properties.

Mechanical Property Testing

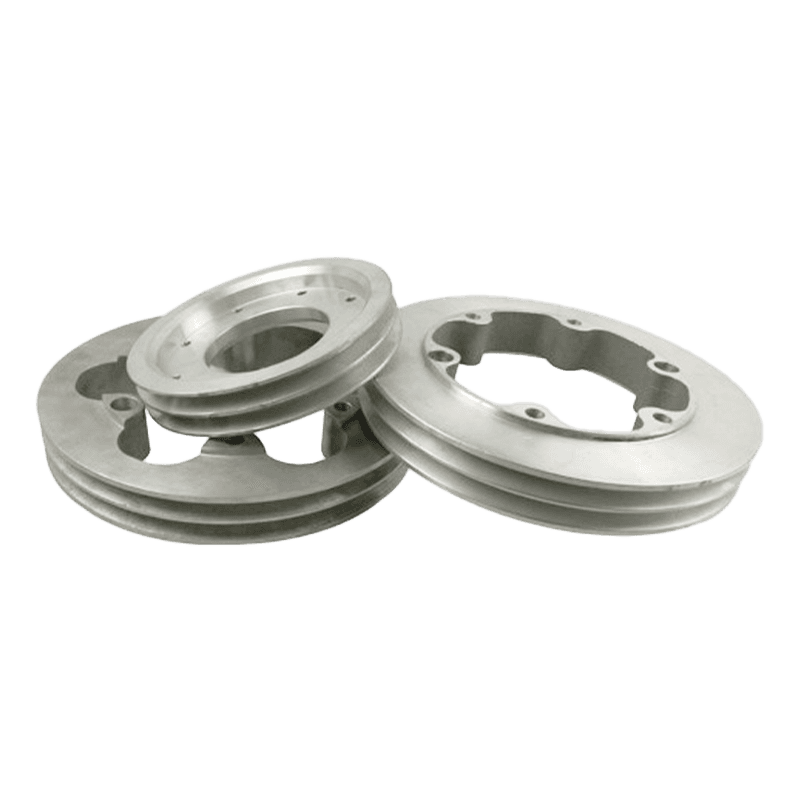

Tensile, hardness, and impact tests verify that castings achieve required strength characteristics. Test specimens either machined from castings or cast separately undergo controlled loading to measure yield strength, ultimate tensile strength, elongation, and hardness. Results must meet specifications for the particular aluminum alloy and intended application, whether for high-strength/low-weight uses or other performance requirements.

Chemical Composition Analysis

Spectroscopic methods confirm alloy composition matches specifications, as small amounts of alloying elements significantly influence aluminum's properties. Improper ratios of silicon, copper, magnesium, or other additives can lead to inadequate strength, poor corrosion resistance, or casting difficulties. Chemical analysis also detects unwanted impurities that might degrade performance.

Corrosion Resistance Evaluation

Testing evaluates the protective aluminum oxide layer's effectiveness through salt spray exposure or other accelerated corrosion methods. The passive film should renew itself spontaneously when damaged to maintain protection. Castings intended for harsh environments require thorough corrosion testing to ensure long-term durability despite surface imperfections or microstructural variations.

Dye Penetrant Inspection

This surface crack detection method uses colored or fluorescent dyes that seep into discontinuities. After cleaning and applying penetrant, inspectors remove excess dye and apply developer to draw out trapped penetrant, highlighting surface-breaking defects. The technique effectively finds fine cracks, porosity, or other surface flaws that might escape visual inspection alone.

Ultrasonic Testing

High-frequency sound waves detect internal flaws by analyzing reflected signals. Changes in material density or the presence of voids alter wave propagation, creating identifiable patterns. Ultrasonic methods can measure wall thickness and identify subsurface defects without damaging castings, though surface preparation and couplant use affect accuracy.

Leak Testing Procedures

For pressure-sensitive applications, various leak testing methods verify casting integrity. Techniques range from simple air-under-water bubble tests to sophisticated mass spectrometer helium leak detection. The appropriate method depends on required sensitivity, with quantitative measurements possible for critical components where even minor leaks could cause failure.

Machining Trial Evaluation

Sample machining operations test castings' workability and reveal potential issues before full production. Problems like excessive tool wear, poor surface finish, or unexpected chip formation may indicate microstructural abnormalities. Successful machining confirms the material's formability and helps establish optimal cutting parameters for production processing.

Statistical Process Control Monitoring

Ongoing quality tracking through SPC methods identifies trends in casting characteristics. Control charts for critical dimensions, porosity levels, or mechanical properties help detect process drift before it produces rejectable parts. Consistent data collection allows for early corrective actions and demonstrates long-term process capability.

Customer-Specific Validation Testing

Final quality confirmation often involves application-specific tests that simulate actual service conditions. These might include pressure cycling, thermal shock, vibration resistance, or other performance validations tailored to the casting's end use. Such testing provides the most direct assessment of whether castings will perform as required in their intended environment.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский