What are the advantages and disadvantages of using zinc alloy die-cast auto parts in automotive structural parts and decorative parts?

17-09-20251. Introduction to Zinc Alloy Die-Cast Auto Parts

Zinc alloy die-casting is a widely used method in the automotive industry, producing both structural parts and decorative parts with high dimensional accuracy. The process involves injecting molten zinc alloy into a mold under high pressure, resulting in components that are strong, detailed, and uniform. These auto parts are popular due to their adaptability for complex designs and their ability to integrate structural and decorative functions in vehicles. When considering their application in both structural and decorative parts, it is necessary to evaluate their advantages and disadvantages to understand their full impact on automotive manufacturing.

2. Material Characteristics of Zinc Alloys

Zinc alloys used in die-casting are typically blends of zinc with elements such as aluminum, magnesium, and copper. These combinations provide mechanical strength, resistance to wear, and enhanced casting properties. Zinc alloys are known for their fluidity, which allows them to create parts with intricate designs and thin walls. This property makes them suitable for decorative auto parts, while their strength and stability allow them to be used in certain structural applications. However, their physical properties also introduce limitations in comparison to other materials such as aluminum or steel.

3. Advantages in Automotive Structural Parts

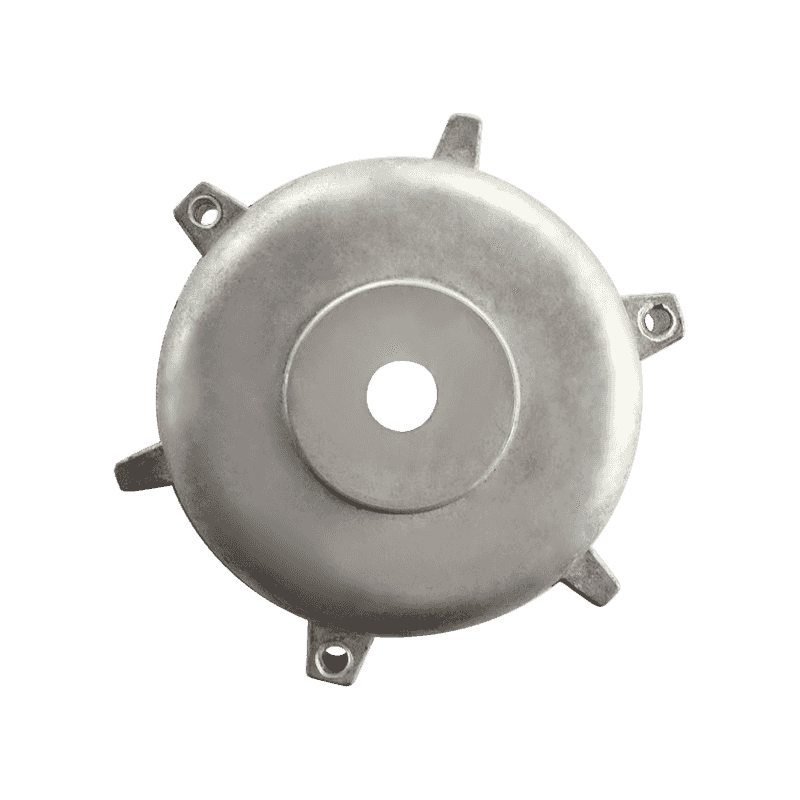

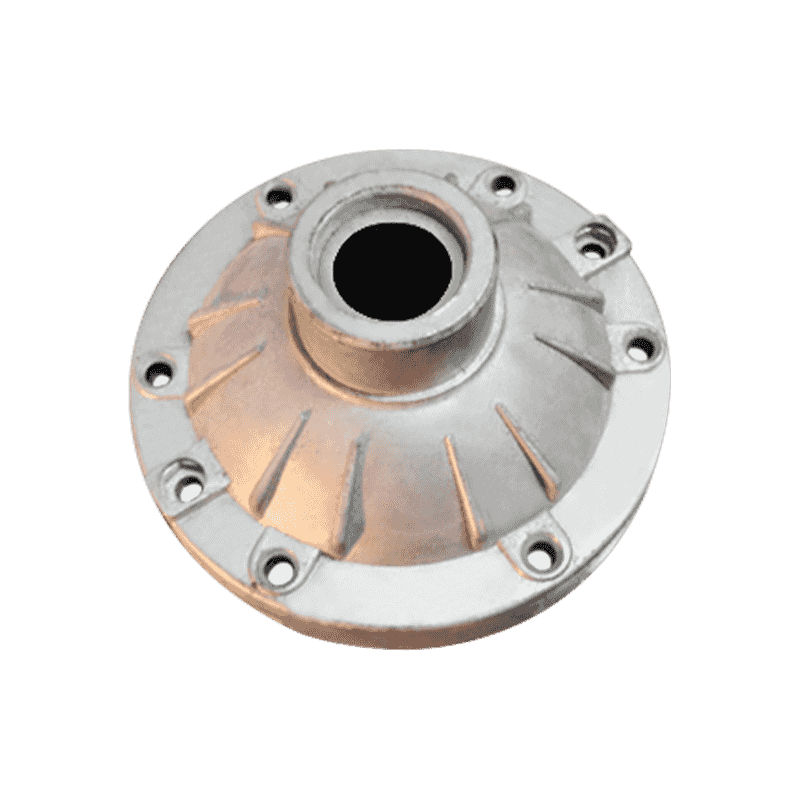

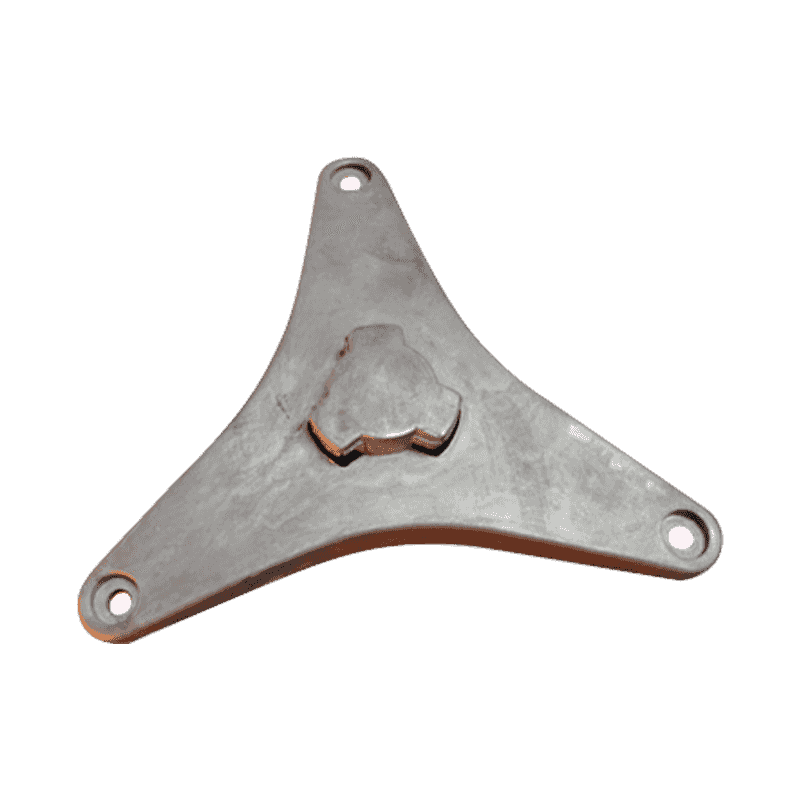

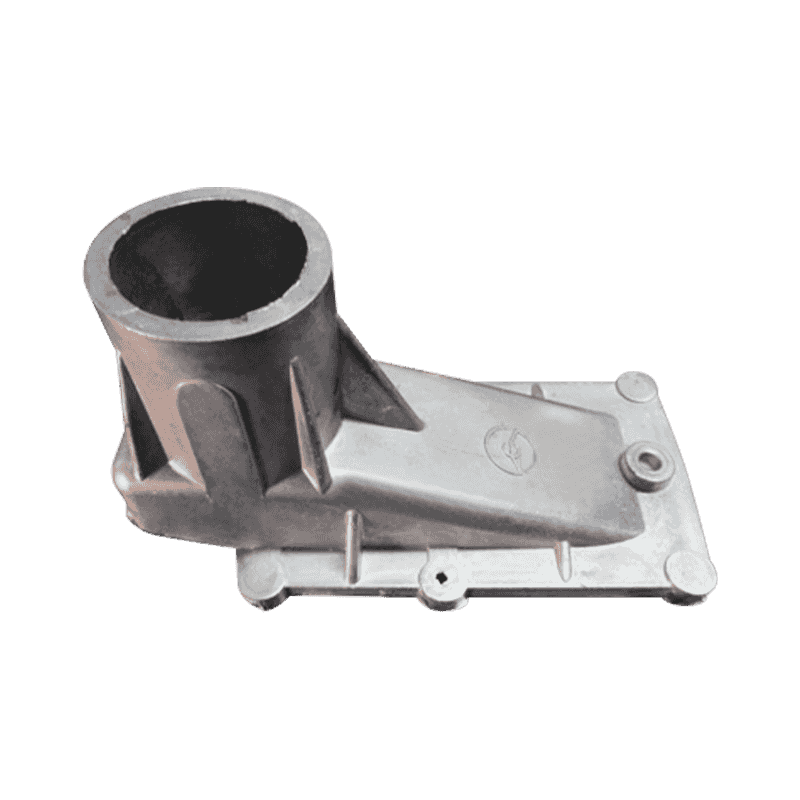

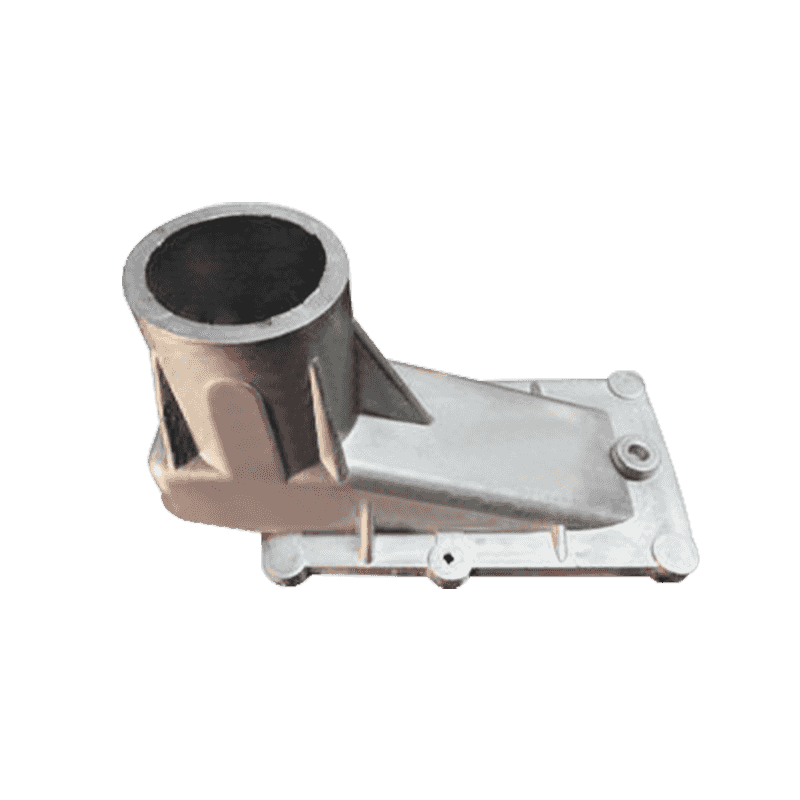

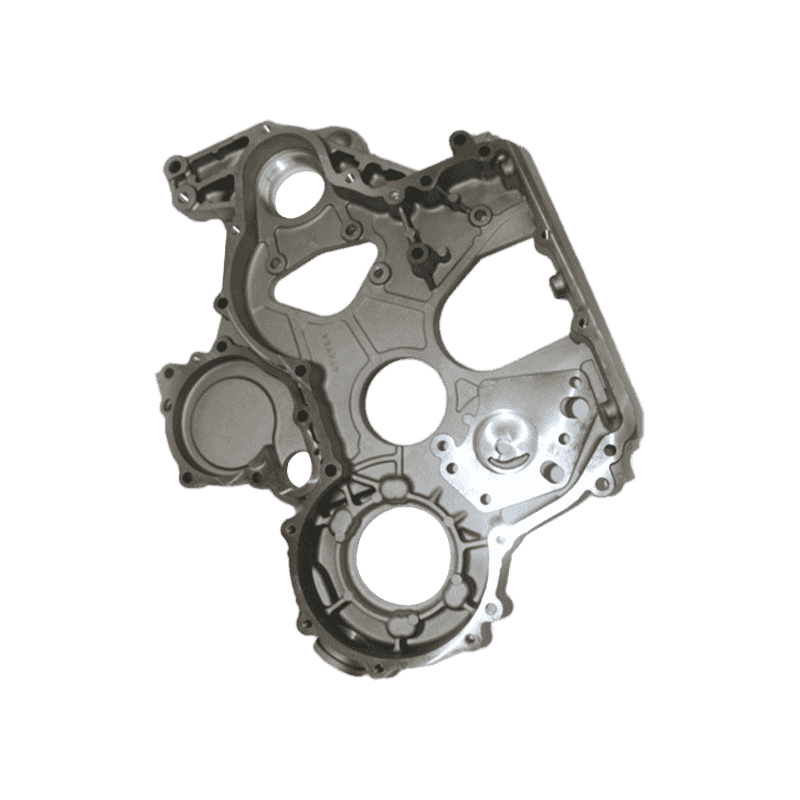

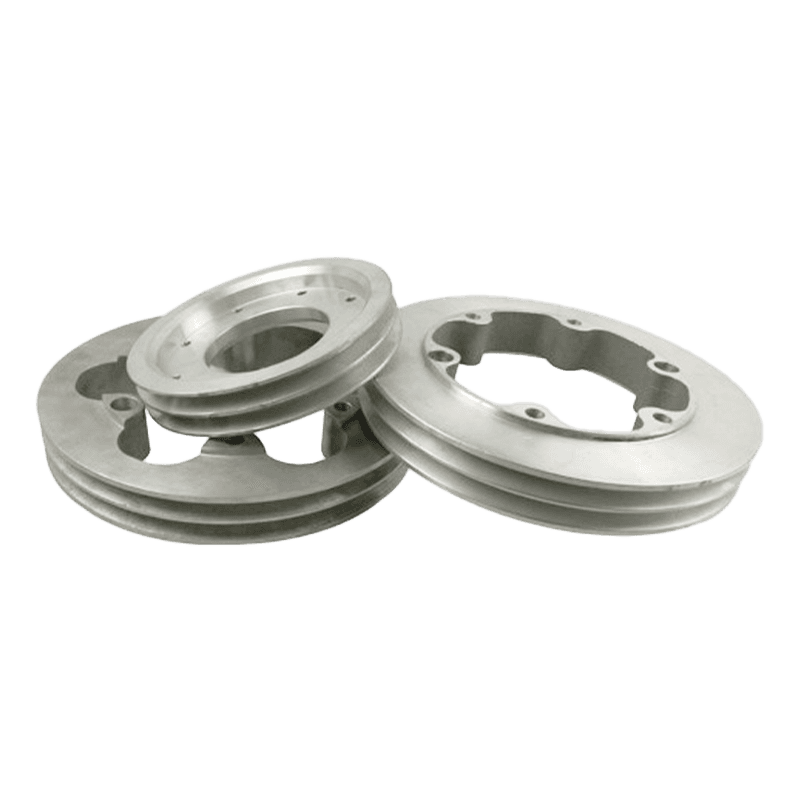

When used in structural parts, zinc alloy die-cast components provide several advantages. They allow for the production of complex shapes with uniform strength distribution, which is important in automotive frames, housings, and connectors. Their ability to maintain tight tolerances ensures compatibility and functionality. Additionally, zinc alloys have high impact resistance, providing safety and reliability in certain structural applications. Their recyclability also adds value in sustainable automotive manufacturing practices.

4. Disadvantages in Automotive Structural Parts

Despite these advantages, zinc alloys have limitations in structural applications. Their density is higher than that of aluminum, leading to heavier parts that may reduce overall vehicle efficiency. Zinc alloys also have lower melting points, which may limit their performance under high-temperature conditions within the vehicle. In certain load-bearing applications, steel or aluminum alloys may be preferred due to higher tensile strength. These limitations must be carefully considered when choosing zinc alloy die-cast components for structural purposes.

5. Advantages in Automotive Decorative Parts

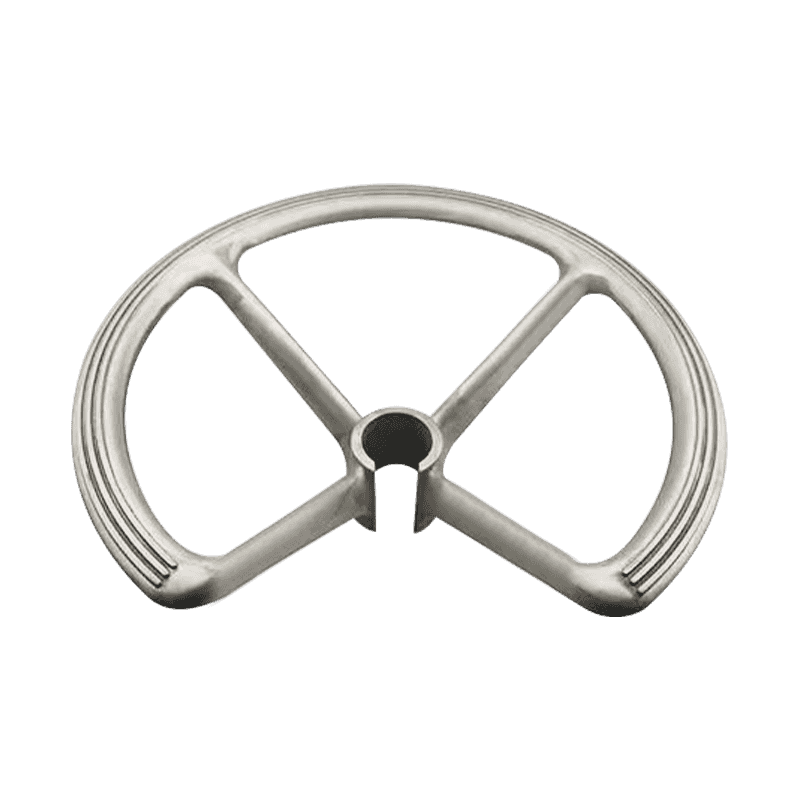

Zinc alloy die-cast parts are particularly valued in decorative automotive applications such as trims, emblems, handles, and interior components. Their excellent casting fluidity allows for detailed surface finishes and complex designs, enhancing the aesthetic appeal of vehicles. Zinc alloys can be easily plated, painted, or polished, offering a wide range of surface treatments. This flexibility makes them ideal for decorative applications where appearance and finishing are primary considerations. Their durability also ensures that decorative elements retain their look even after prolonged use.

6. Disadvantages in Automotive Decorative Parts

While zinc alloys perform well in decorative parts, there are challenges to consider. Exposure to moisture and corrosive environments can affect the longevity of surface finishes if protective coatings are not applied correctly. In addition, although zinc alloys offer good dimensional stability, decorative parts may still face issues with thermal expansion in high-temperature environments. For applications that demand ultra-lightweight materials, alternatives like plastics or aluminum may sometimes be more suitable.

7. Cost Considerations of Zinc Alloy Die-Cast Parts

The cost of using zinc alloy die-cast parts is influenced by both material and process efficiency. Zinc alloys are relatively affordable, and the die-casting process allows for mass production of identical parts with minimal post-processing. This reduces labor costs and manufacturing time. However, the higher density of zinc compared to aluminum can increase the material cost per unit volume. In decorative applications, additional expenses for plating or painting may also affect overall cost efficiency.

| Cost Factor | Zinc Alloy Die-Cast Parts | Alternative Materials |

|---|---|---|

| Material Cost | Moderate, with wide availability | Aluminum is lighter but more expensive; plastics are cheaper |

| Manufacturing Efficiency | High due to precision die-casting | Varies, often requiring more machining |

| Finishing Costs | Additional plating or painting may be required | Plastics often need less finishing; steel may need coatings |

8. Environmental and Sustainability Aspects

Sustainability is a growing concern in automotive manufacturing. Zinc alloys are fully recyclable, which aligns with environmental goals. The die-casting process also minimizes material waste due to high yield efficiency. Compared to plastics, zinc alloys provide longer-lasting parts, reducing replacement frequency and waste generation. However, energy consumption in the die-casting process and the requirement for coatings in decorative applications introduce additional environmental considerations that must be balanced.

9. Mechanical Performance Comparison

The mechanical properties of zinc alloy die-cast parts influence their suitability for different automotive applications. In structural components, properties such as tensile strength, hardness, and impact resistance are key, while in decorative parts, surface finish and dimensional stability are prioritized. The following table provides a comparison of mechanical performance aspects of zinc alloys against natural alternatives such as aluminum and steel.

| Property | Zinc Alloy Die-Cast Parts | Aluminum Parts | Steel Parts |

|---|---|---|---|

| Density | Higher, leading to heavier parts | Lower, lightweight advantage | High, significantly heavier |

| Tensile Strength | Moderate, suitable for light loads | Moderate to high depending on alloy | High, best for heavy loads |

| Impact Resistance | Good under normal conditions | Moderate | High |

| Corrosion Resistance | Good with coatings | Good, naturally protective oxide | Requires coatings to resist corrosion |

10. Applications in Modern Automotive Design

Modern automotive design integrates zinc alloy die-cast parts in both structural and decorative roles. Structural applications include housings, brackets, and connectors, while decorative applications cover trims, emblems, and handles. The choice to use zinc alloy often depends on balancing durability, aesthetics, and cost considerations. For example, zinc alloy handles and trims offer both strength and detailed finishes, while structural components benefit from their dimensional stability.

11. Advantages and Disadvantages Summary

The advantages and disadvantages of zinc alloy die-cast auto parts can be summarized in the table below, highlighting the differences between structural and decorative applications:

| Application | Advantages | Disadvantages |

|---|---|---|

| Structural Parts | High impact resistance, dimensional stability, recyclability | Heavier than aluminum, lower temperature tolerance, moderate tensile strength |

| Decorative Parts | Excellent surface finish, complex designs, easy plating and painting | Requires protective coatings, possible thermal expansion issues |

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский