How are aluminium profile electronic fittings used in consumer electronics, industrial equipment and communications equipment?

24-09-2025Introduction to Aluminium Profile Electronic Fittings

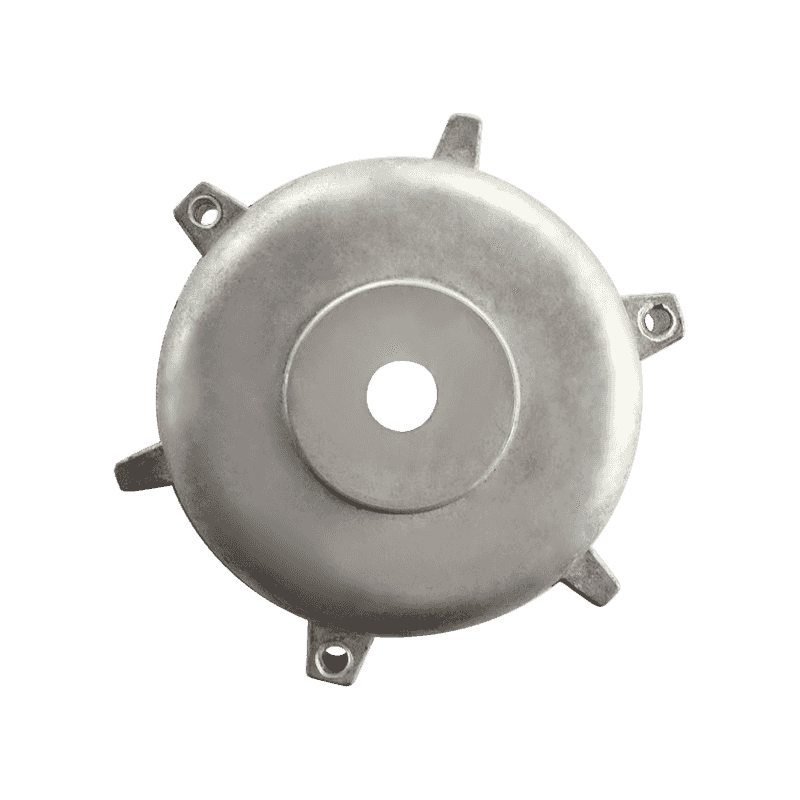

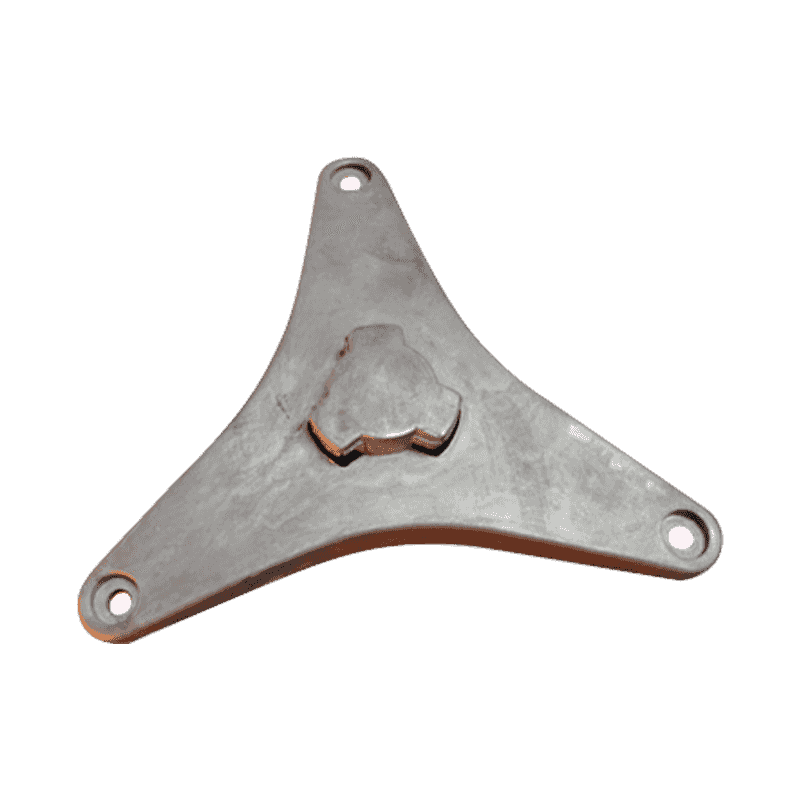

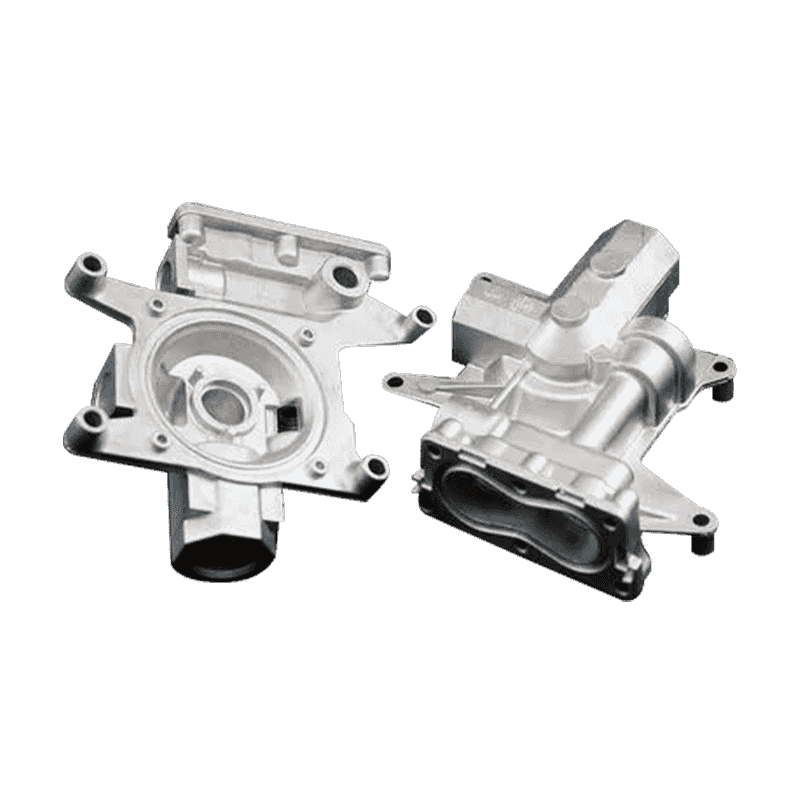

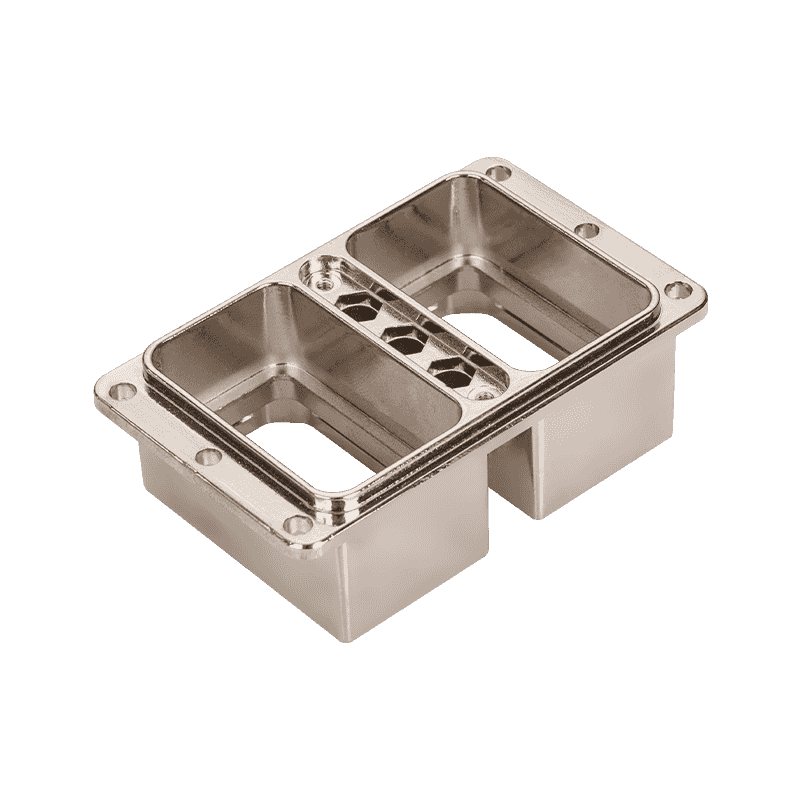

Aluminium profile electronic fittings are structural and functional components that integrate aluminium profiles into various electronic systems. These fittings are used for assembling, connecting, supporting, or protecting electronic devices across multiple fields. Due to their lightweight structure, corrosion resistance, thermal conductivity, and adaptability, aluminium profile fittings are applied in consumer electronics, industrial equipment, and communications equipment. Their role is not limited to providing physical support; they also help improve heat dissipation, enable modular designs, and maintain durability under different operating conditions. By understanding how aluminium profile electronic fittings are used in different industries, one can appreciate their value in modern engineering applications.

Use of Aluminium Profile Electronic Fittings in Consumer Electronics

In consumer electronics, aluminium profile fittings are employed to assemble and house devices such as laptops, tablets, televisions, audio equipment, and gaming consoles. Their lightweight nature allows manufacturers to create slim and portable products, while their ability to dissipate heat helps manage the thermal load generated by processors and circuits. Aluminium profile fittings also contribute to a sleek and modern appearance, enhancing the aesthetic value of consumer devices. Beyond aesthetics and structural roles, these fittings improve device reliability by protecting internal components from external stress, vibrations, and temperature fluctuations. With the trend toward compact and multifunctional devices, aluminium profiles provide the flexibility to integrate multiple features into a single assembly without compromising strength.

Use of Aluminium Profile Electronic Fittings in Industrial Equipment

Industrial equipment requires robust housing and reliable structural components to perform under heavy-duty conditions. Aluminium profile electronic fittings are widely used in machine control panels, automation systems, power supply enclosures, and test equipment. Their corrosion resistance ensures long service life even in challenging environments where humidity, dust, and temperature variations are present. The modular nature of aluminium profiles allows engineers to design enclosures that can be expanded, modified, or adapted for specific functions, making them ideal for rapidly evolving industrial systems. Additionally, their electrical conductivity and grounding capabilities add an extra layer of protection for sensitive electronics, ensuring that industrial equipment functions safely and consistently.

Use of Aluminium Profile Electronic Fittings in Communications Equipment

Communications equipment such as server racks, base stations, satellite systems, and network routers depend heavily on aluminium profile electronic fittings. These fittings are used to create enclosures, racks, and structural supports that can withstand constant operation and environmental challenges. The excellent thermal conductivity of aluminium assists in cooling sensitive communication circuits, which is essential to maintain signal stability and prevent overheating in high-capacity data systems. Furthermore, aluminium profiles allow for modular construction of large communication frameworks, making them adaptable to the rapid changes in network infrastructure. Lightweight yet durable, they reduce the overall weight of equipment, which is particularly valuable in mobile communication towers or satellite communication systems where weight optimization is critical.

Heat Dissipation Benefits of Aluminium Profiles

One of the defining advantages of aluminium profile electronic fittings across all sectors is their contribution to heat dissipation. Electronic components generate significant amounts of heat during operation, and improper thermal management can reduce lifespan and efficiency. Aluminium’s natural thermal conductivity allows these fittings to act as heat sinks, distributing heat away from sensitive components. In consumer electronics, this ensures compact devices remain comfortable to use. In industrial settings, it prevents overheating during continuous operation. In communication equipment, effective heat management maintains uninterrupted data transfer and stable network performance.

Structural and Design Flexibility

Aluminium profile electronic fittings provide structural and design flexibility that other materials often cannot match. They can be easily cut, drilled, bent, and joined, making them suitable for custom electronic assemblies. This adaptability allows manufacturers to create both standardized products and specialized enclosures for niche applications. The design flexibility is particularly useful in industrial and communication systems where scalability and modularity are critical. Consumer electronics also benefit from this flexibility by offering products that are slim, lightweight, and capable of integrating multiple functional components within limited space.

Durability and Environmental Resistance

Durability is an essential factor when selecting electronic fittings, and aluminium profiles provide resilience against mechanical stress, corrosion, and wear. In consumer electronics, this ensures that devices remain resistant to daily handling and exposure to environmental factors. In industrial equipment, aluminium profiles maintain their structural integrity under mechanical loads, vibrations, and temperature fluctuations. In communication systems, where equipment may be installed outdoors or in remote environments, aluminium’s resistance to corrosion from humidity and weathering becomes crucial. This durability supports long-term performance and reduces the frequency of maintenance or replacement.

Comparative Table of Applications

The following table outlines the primary uses of aluminium profile electronic fittings in consumer electronics, industrial equipment, and communications equipment.

| Application Area | Role of Aluminium Profile Fittings | Key Benefits |

|---|---|---|

| Consumer Electronics | Device housings, connectors, support structures | Lightweight design, heat dissipation, sleek appearance |

| Industrial Equipment | Control panel frames, machine enclosures, automation supports | Durability, modular design, grounding capability |

| Communications Equipment | Server racks, antenna housings, network enclosures | Thermal management, lightweight strength, scalability |

Electrical and Safety Considerations

Aluminium profile electronic fittings also play a role in ensuring electrical safety and system reliability. Their conductive properties allow them to act as grounding components, which protect sensitive circuits from electrical surges or interference. In consumer electronics, this prevents malfunction and improves user safety. In industrial equipment, grounding reduces the risk of electrical faults that could disrupt production processes. In communication systems, aluminium profiles help maintain signal clarity by minimizing electromagnetic interference. Incorporating these fittings into electrical safety designs ensures reliable operation across all sectors.

Sustainability and Recycling

Aluminium is highly recyclable, and the use of aluminium profile electronic fittings contributes positively to sustainability efforts in manufacturing. Recycling aluminium requires significantly less energy than producing new material, which reduces environmental impact. In consumer electronics, where short product life cycles are common, recyclability supports circular economy practices. Industrial equipment benefits from aluminium’s reusability in updated or modified systems. In communications equipment, recyclable aluminium reduces waste when systems are replaced or upgraded. Sustainability is increasingly important in modern engineering, and aluminium profiles align with these goals by supporting energy-efficient recycling practices.

Challenges in Using Aluminium Profile Electronic Fittings

Despite their advantages, aluminium profile fittings also present certain challenges. Aluminium is softer compared to steel, meaning it may deform under extreme mechanical loads if not reinforced properly. Additionally, while aluminium has natural corrosion resistance, it may still be susceptible to galvanic corrosion when in contact with other metals. In consumer electronics, these issues are less pronounced due to controlled environments, but in industrial and communication systems, careful design and protective coatings are necessary to ensure long-term reliability. These challenges can be addressed through engineering solutions such as anodizing, powder coating, and alloying, which enhance the mechanical and environmental properties of aluminium profiles.

Future Trends of Aluminium Profile Electronic Fittings

The demand for aluminium profile electronic fittings is expected to grow as electronics continue to evolve in complexity and function. In consumer electronics, the trend toward thinner and more powerful devices will increase reliance on aluminium for both structural support and thermal management. In industrial systems, the rise of automation and robotics will require modular and durable electronic housings. In communications, the expansion of 5G and satellite networks will demand lightweight and efficient enclosures capable of supporting high-performance equipment. Aluminium profiles, with their adaptability and sustainability, are likely to remain central to these future developments.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский