Can aluminum extrusion and machining processes guarantee a smooth, scratch-free, and impurity-free surface on the aluminum profiles?

05-02-2026Introduction to Aluminum Extrusion and Machining Processes

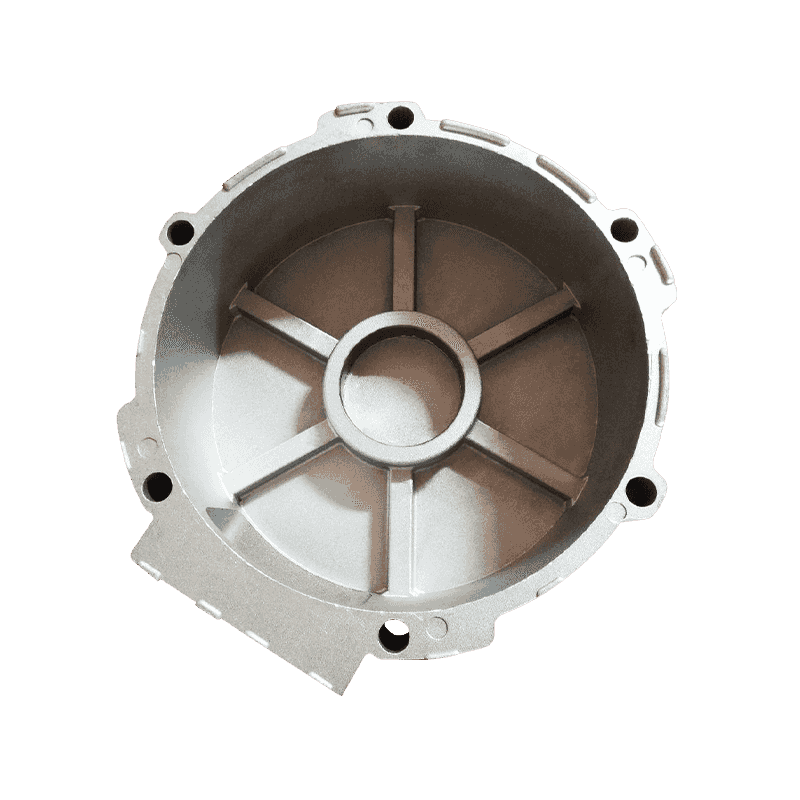

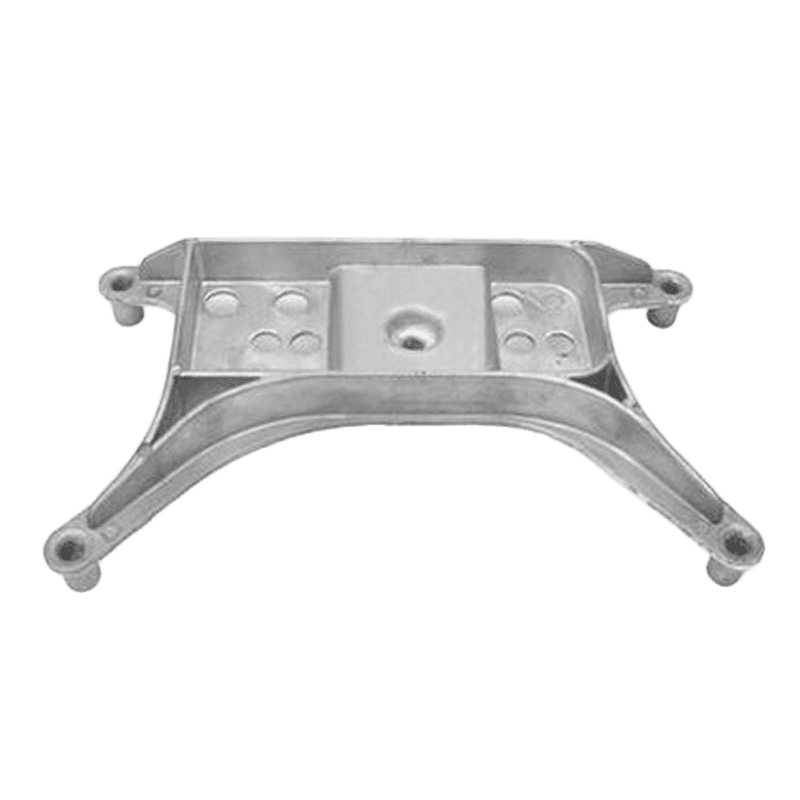

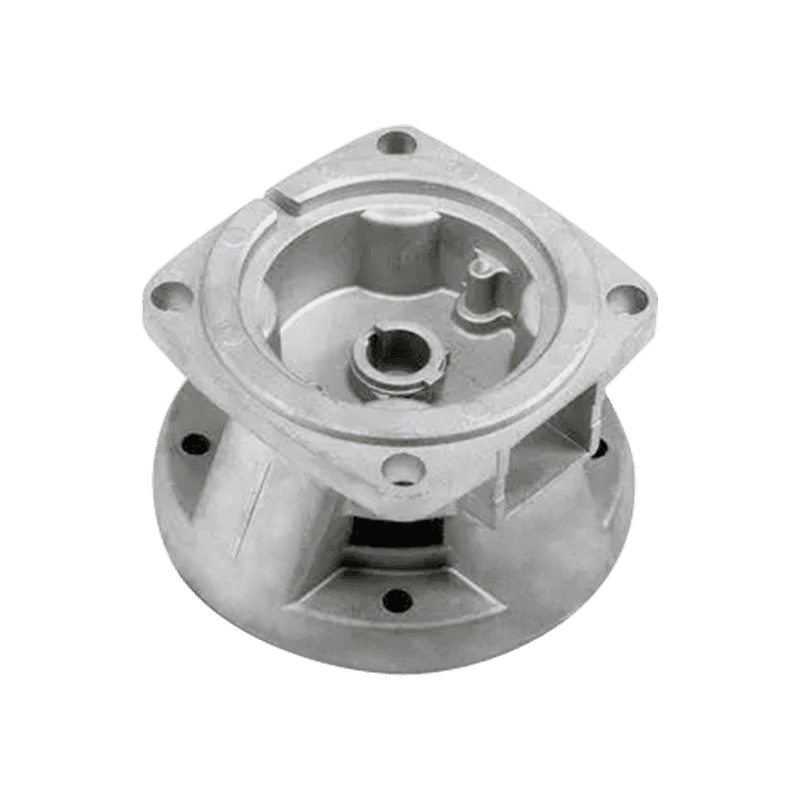

Aluminum extrusion and machining are widely used techniques in the manufacturing of aluminum profiles. These processes are essential for producing aluminum parts that are used in a variety of industries, including construction, automotive, aerospace, and electronics. Aluminum extrusion involves forcing heated aluminum through a die to create profiles with specific shapes, while machining involves the removal of material from the extruded aluminum to achieve the desired dimensions and surface quality. A common goal in these processes is to produce aluminum profiles that are smooth, scratch-free, and free from impurities, as these qualities are often crucial for both functional and aesthetic purposes. However, achieving these qualities requires careful consideration of several factors, and it is not always guaranteed that extrusion and machining processes will consistently produce flawless surfaces.

The Aluminum Extrusion Process and Its Impact on Surface Quality

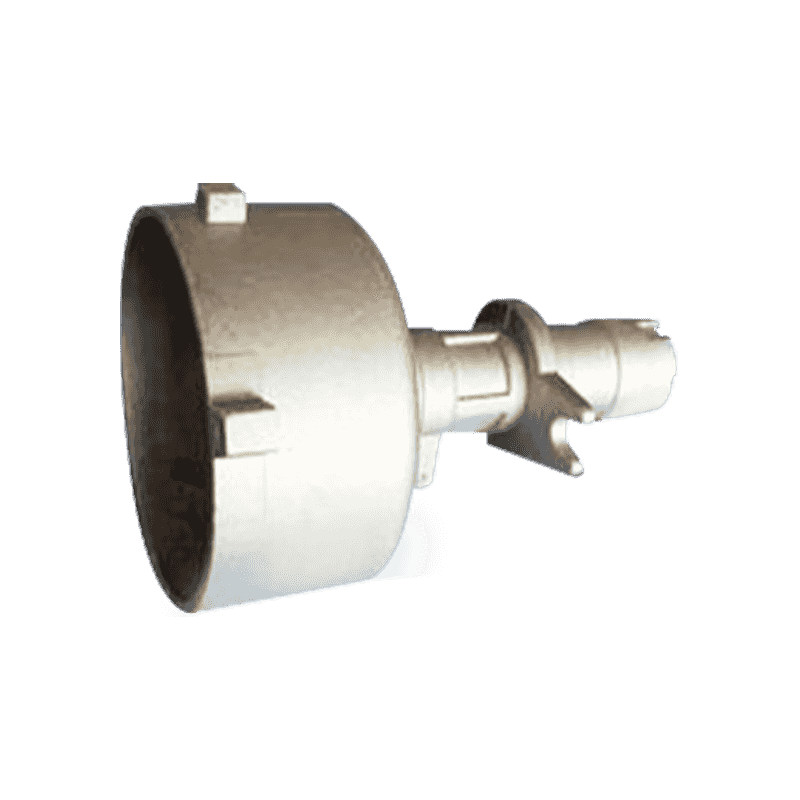

Aluminum extrusion involves pushing a billet of aluminum through a die, which shapes the aluminum into a desired profile. The process itself can have an impact on the surface quality of the final product. During extrusion, the aluminum is subjected to high temperatures and mechanical forces that cause it to flow through the die. The quality of the extrusion can vary depending on several factors, including the temperature of the billet, the pressure applied during extrusion, and the condition of the die itself.

One of the challenges in aluminum extrusion is the potential for surface imperfections, such as die marks, surface oxidation, or slight variations in thickness. The temperature and speed at which the extrusion is performed play a significant role in how smooth the surface will be. If the aluminum is too hot or the extrusion process is too rapid, it can lead to uneven flow, causing roughness or streaks on the surface. Additionally, oxidation can occur when the aluminum comes into contact with air at high temperatures, resulting in a dull or discolored finish. While these issues can be minimized through careful control of process parameters, it is difficult to guarantee a perfectly smooth, scratch-free surface in all cases without additional treatments.

Machining Processes and Their Role in Surface Finish

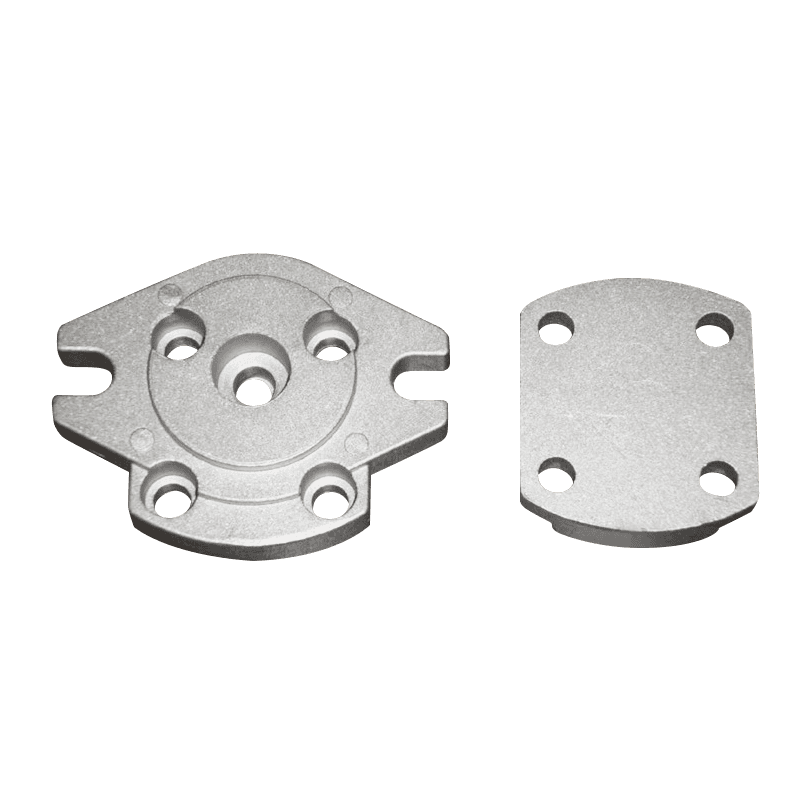

Machining processes, such as milling, turning, and grinding, are often employed after extrusion to refine the aluminum profiles and achieve precise dimensions and surface finishes. Machining is particularly important when tight tolerances or smooth surfaces are required. Depending on the specific requirements, machining can be used to remove excess material, smooth out rough edges, or improve the surface finish of the aluminum profile.

While machining can significantly improve the surface quality, it is not always a guarantee that the result will be perfectly smooth and scratch-free. The quality of the machining process depends on several factors, including the type of machining used, the condition of the cutting tools, the speed and feed rates, and the lubrication applied during the process. For example, high-speed machining can generate heat, which may affect the aluminum surface and cause slight distortion or marks. Similarly, dull or worn cutting tools can lead to surface defects, such as scratches or roughness, that are difficult to eliminate even after polishing.

Challenges in Achieving a Scratch-Free Surface

One of the most common concerns in both extrusion and machining processes is the potential for scratches on the aluminum surface. Scratches can be caused by various factors, including improper handling, tool wear, and contamination during the manufacturing process. During extrusion, the aluminum may come into contact with the die or other surfaces that can leave marks on the surface. Even after machining, if the aluminum is not handled carefully or if abrasive particles are present in the environment, scratches may occur.

Scratches are particularly problematic because they can affect both the aesthetic and functional qualities of the aluminum profile. In some cases, scratches may be cosmetic and may not affect the overall performance of the part. However, in applications where appearance is important, such as in architectural finishes or consumer products, scratches can be a significant issue. To prevent scratches, manufacturers often take extra precautions during handling, use protective coatings, or apply additional finishing processes like polishing or anodizing to improve surface integrity and minimize the risk of damage.

Impurity-Free Surface and Contamination Risks

Another important consideration when working with aluminum profiles is ensuring that the surface remains free of impurities. Impurities can come from various sources, including contamination from lubricants, dust, dirt, or even residual materials from previous processes. The presence of impurities on the surface of the aluminum can interfere with subsequent treatments, such as painting, coating, or anodizing, and can also negatively affect the performance of the aluminum in certain applications.

During the extrusion process, it is possible for the aluminum to pick up impurities from the die or from the environment, especially if the process is not properly controlled. The use of high-quality materials and maintaining a clean production environment are essential for minimizing the risk of contamination. Similarly, during machining, impurities can be introduced by the cutting tools, coolant, or the handling of the material. Regular cleaning and inspection of the machinery, as well as the use of appropriate lubricants and coolants, are necessary to avoid introducing contaminants that can affect the surface quality of the aluminum profiles.

Post-Processing Treatments for Improving Surface Quality

To address the challenges of achieving a smooth, scratch-free, and impurity-free surface on aluminum profiles, manufacturers often rely on various post-processing treatments. These treatments can help enhance the surface finish and correct any imperfections that may have occurred during extrusion or machining.

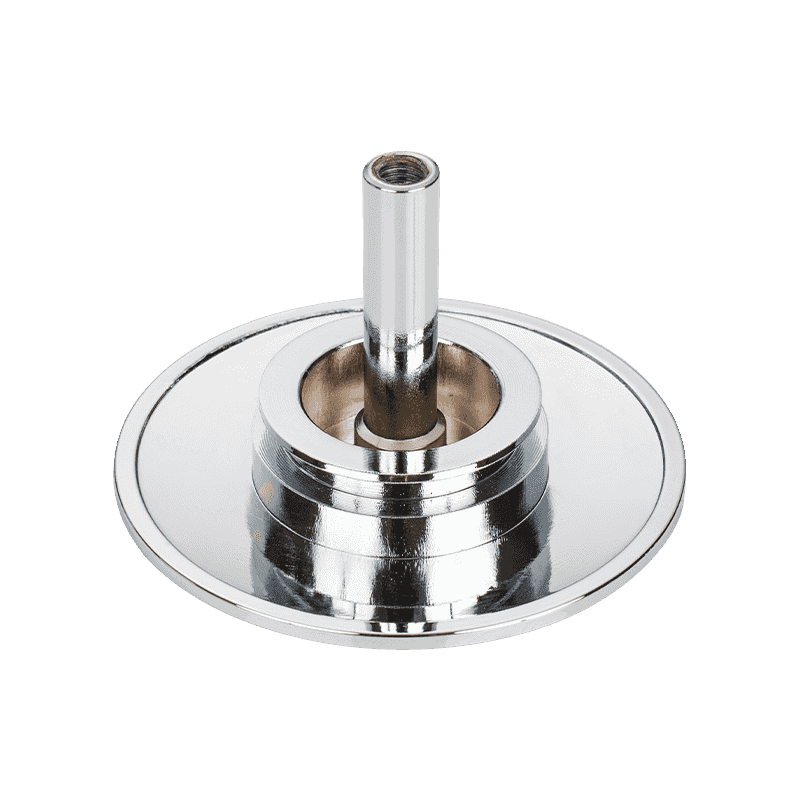

One common post-processing treatment is polishing, which can help smooth out minor surface roughness and remove any visible scratches. Polishing is typically done using abrasive materials or specialized machines that refine the surface to a high level of smoothness. However, polishing may not be able to eliminate deep scratches or imperfections, and it may not be suitable for all types of aluminum profiles.

Anodizing is another post-processing treatment that can improve both the appearance and durability of aluminum profiles. Anodizing involves the electrochemical conversion of the aluminum surface into a thick oxide layer, which provides a smooth, uniform finish that is resistant to scratches and corrosion. Anodizing can also help remove impurities from the surface by creating a clean, uniform layer. This process not only improves the surface quality but also adds additional protection against wear and tear.

Limitations in Guaranteeing a Flawless Surface

While extrusion, machining, and post-processing treatments can significantly improve the surface quality of aluminum profiles, it is important to understand that achieving a completely smooth, scratch-free, and impurity-free surface may not always be guaranteed. There are inherent limitations in the manufacturing process that can make it difficult to eliminate all imperfections. Factors such as material properties, environmental conditions, and the precision of the machinery all contribute to the final surface quality. Additionally, even with advanced technologies and treatments, it is possible for small imperfections to remain, especially in large-scale production where consistency across thousands of parts can be challenging.

Manufacturers typically set acceptable limits for surface quality, depending on the intended application of the aluminum profile. For example, parts that will be used in structural applications may have more lenient surface quality standards compared to those that will be visible to consumers. In high-precision industries, such as aerospace or electronics, the surface finish requirements may be much stricter, and additional steps may be taken to ensure that the profiles meet the necessary standards.

Quality Control and Monitoring in the Manufacturing Process

To ensure that aluminum profiles meet the desired surface quality standards, manufacturers often implement stringent quality control measures throughout the extrusion and machining processes. This includes regular inspection of the raw materials, monitoring of process parameters such as temperature and pressure, and in-process testing of surface roughness. Automated systems and sensors are sometimes used to detect surface defects in real-time, allowing for immediate corrective action.

In addition to in-process monitoring, final inspection and testing are essential to ensure that the finished aluminum profiles meet the required specifications. Surface quality can be evaluated using various methods, including visual inspection, surface profilometry, and ultrasonic testing. These techniques help identify any imperfections, such as scratches, pits, or contaminants, and ensure that the profiles meet the necessary standards for their intended applications.

Achieving Smooth and Imperfection-Free Aluminum Profiles

While aluminum extrusion and machining processes are effective in producing high-quality profiles, achieving a perfectly smooth, scratch-free, and impurity-free surface is not always guaranteed. Various factors, including material properties, process control, and handling, can impact the final surface quality. However, through careful design, quality control, and the use of post-processing treatments such as polishing and anodizing, manufacturers can significantly improve the surface finish of aluminum profiles. Ultimately, the success of these processes depends on the specific requirements of the application and the level of quality that can be achieved through various manufacturing and finishing techniques.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский