What are the advantages of zinc alloy power tool accessories die casting?

03-08-2025Material properties and structural adaptability

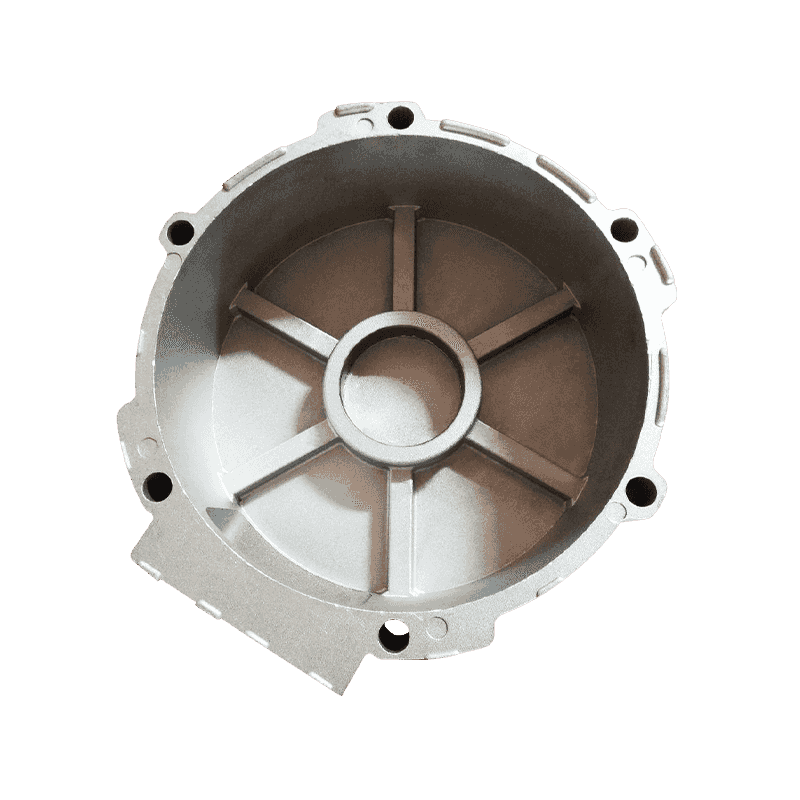

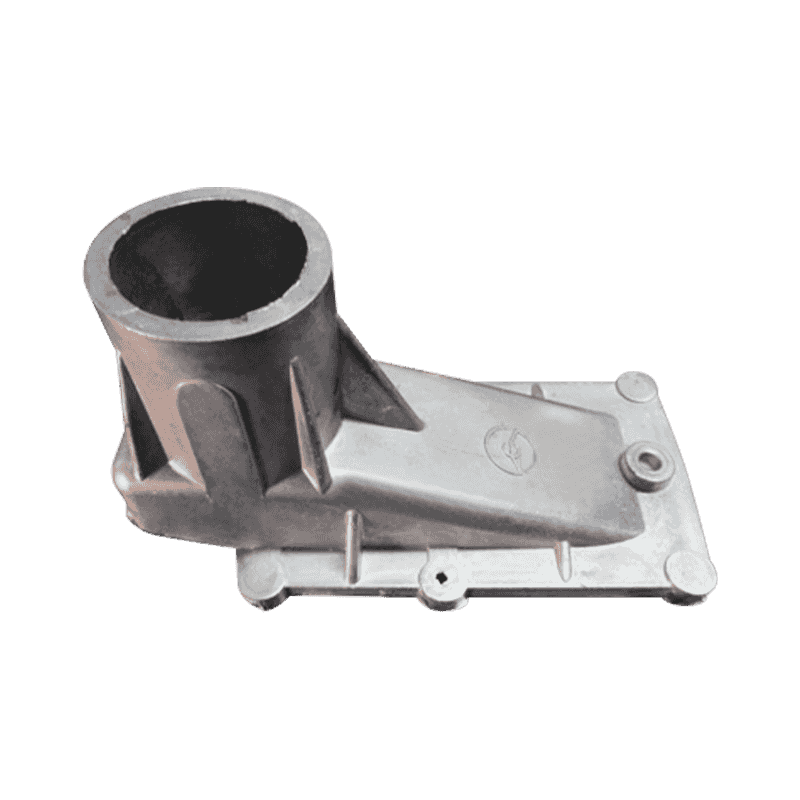

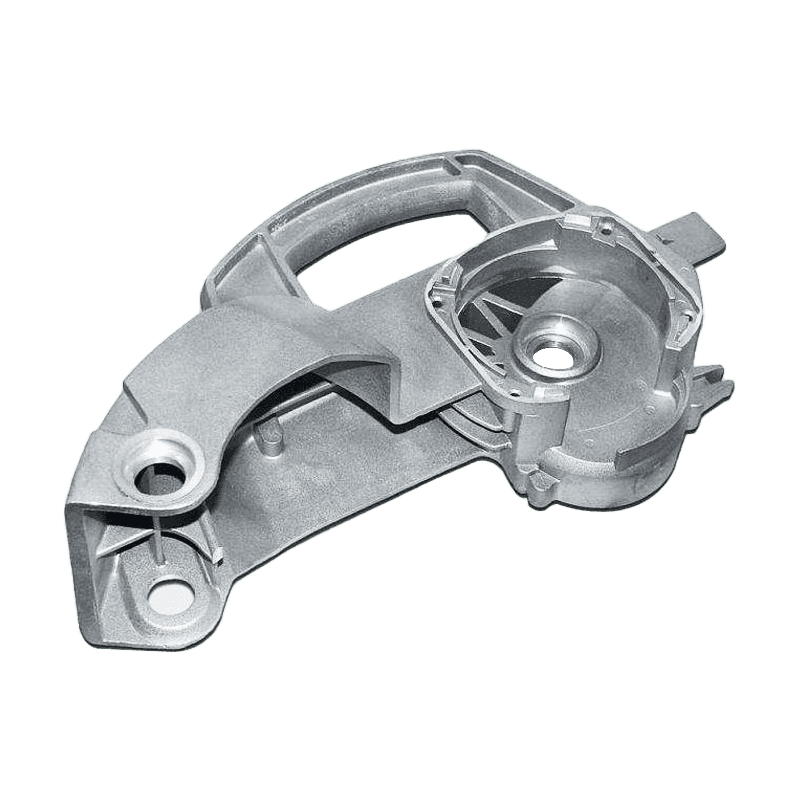

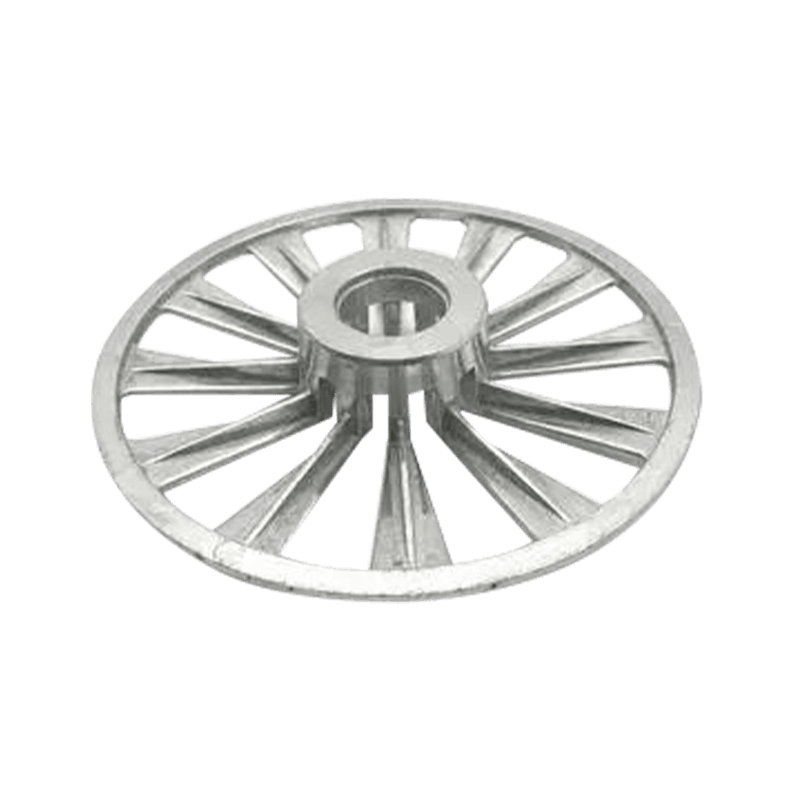

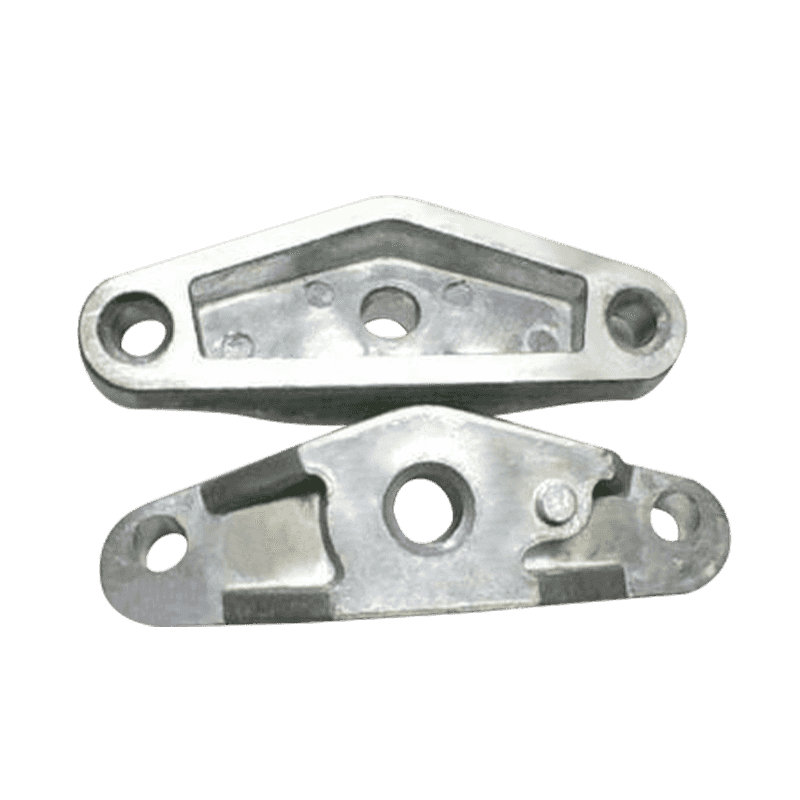

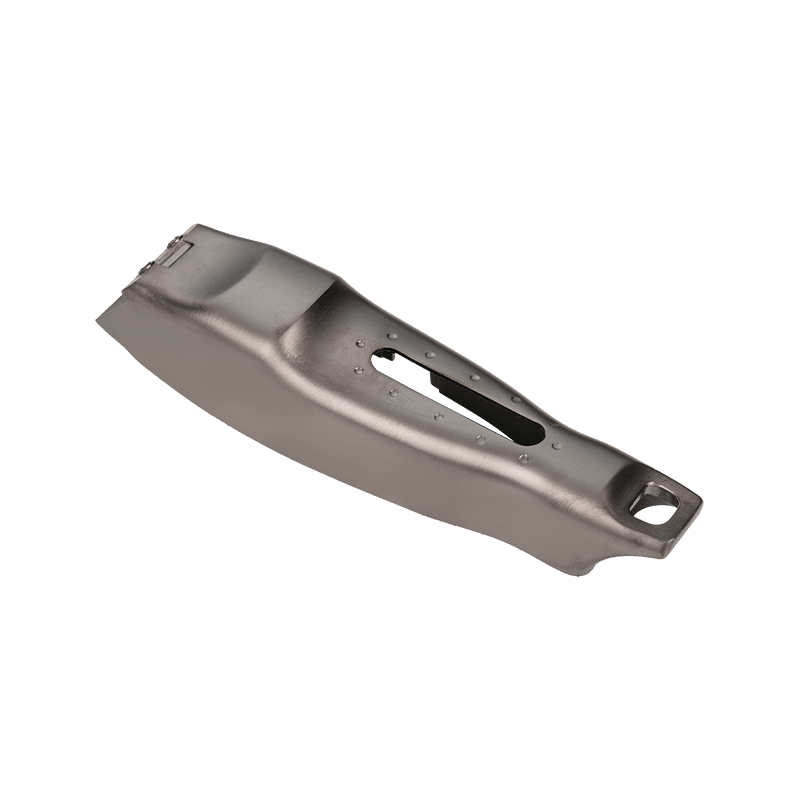

As an important material for die-casting of power tool fittings, zinc alloy has good fluidity and low melting point, which enables it to fill the fine structure of the mold well during the die-casting process and realize the molding of complex-shaped parts. This characteristic is very suitable for the manufacturing needs of power tool fittings, because the internal parts of the tool often require fine structures and complex geometric shapes. The toughness and ductility of zinc alloy also provide a certain impact resistance for the parts during use, making them stable in a variety of working environments. Combined with different tool types, the material properties can be optimized by adjusting the alloy composition to meet the requirements of different power tools for wear resistance, strength and surface quality during use.

Precision and stability of die-casting

Die-casting technology shows high dimensional accuracy and repeatability in the production of zinc alloy power tool fittings, which is crucial for the interchangeability and assembly accuracy of power tool parts. Through reasonable mold design and precise process control, die-casting parts can achieve a lower dimensional tolerance range, which helps to reduce the later machining links, thereby reducing the overall production cost. In long-term production, zinc alloy die-casting can also maintain a high consistency, ensuring that the shape and performance of the same batch of products remain stable, meeting the consistency requirements of mass production. In addition, the internal cooling system and pressure control technology can be used to reduce thermal stress during the die-casting process, thereby reducing part deformation and internal defects and improving the overall stability of the parts.

Cost control and production efficiency

Zinc alloy die-casting also has advantages in cost control. Its low melting point and good molding characteristics mean that die-casting equipment can operate at lower energy consumption, thereby reducing energy consumption in the production process. Compared with other metal materials, zinc alloys are also more controllable in raw material procurement and processing costs. The die-casting process has a high degree of automated production capacity, which can complete the molding of a large number of parts in a short period of time, meeting the market's large-scale demand for power tool fittings. This not only improves production efficiency, but also reduces labor costs. In addition, by optimizing the production process and reasonable mold design, the mold service life can be further extended, thereby reducing the additional expenses caused by mold replacement.

Surface quality and post-processing adaptability

Zinc alloy die-castings have a high surface finish, which provides a good basic condition for subsequent surface treatment. For power tool fittings, surface treatment is not only related to aesthetics, but also involves functional requirements such as corrosion resistance, wear resistance and insulation. Zinc alloy parts can easily achieve a variety of surface treatment methods, such as electroplating, spraying, anodizing and chemical plating, to meet the performance requirements in different use environments. In the power tool industry, parts are often exposed to moisture, dust and oily environments. After proper surface treatment, zinc alloy fittings can better resist corrosion and wear and extend their service life.

Balance between lightweight structure and strength

In modern power tool design, the balance between lightweight and structural strength is one of the core goals. Zinc alloy has a high density but allows thinner wall thickness molding, which makes it possible to achieve lightweight design of parts while meeting strength requirements. By optimizing the structural design and wall thickness distribution, the material consumption can be reduced and the overall weight can be reduced, thereby improving the portability and operating comfort of the tool. For users, this combination of lightness and durability can improve the tool's use experience, especially for long-term operations or occasions with high portability requirements.

Defect control and process improvement

In the die-casting process of zinc alloy power tool fittings, pores, cold shuts and surface defects are common quality problems. In order to reduce the impact of these defects on the performance of parts, improvements can be made through vacuum die casting, slow filling, optimized gate and exhaust system and other process means. With the help of advanced mold flow analysis technology, potential defects can be predicted and reduced in the mold design stage, and the stability of the production process can be improved. At the same time, by adding mold cooling channels and improving the pouring system, the temperature balance during the molding process can be improved, thereby improving the quality of the finished product. The comprehensive application of these improvement measures provides a guarantee for the overall quality control of die castings.

Adapt to the diverse needs of power tools

Different types of power tools, such as drilling machines, cutting machines, grinders, etc., have different requirements for fittings in terms of structural strength, wear resistance, heat dissipation performance, etc. The design flexibility of zinc alloy die castings can adapt to the diverse requirements of part structures, especially in complex curved surfaces or internal reinforcement ribs. It has good formability. Through reasonable mold design and process adjustment, the production of personalized parts can be achieved without adding additional processes to meet the special needs of different power tools. This feature is of practical value to power tool manufacturers that produce multiple series and multiple models of products.

Comparison of zinc alloy with other materials

Compared with common die-casting materials such as aluminum alloy and magnesium alloy, zinc alloy has certain advantages in dimensional accuracy, mold life and process stability. Although aluminum alloy has a lower density and is more suitable for extremely lightweight parts, its die-casting mold wears faster and has higher long-term costs. Magnesium alloy performs well in terms of weight, but the material cost and process control are more difficult. In contrast, zinc alloy is more balanced in terms of comprehensive cost, production efficiency and finished product accuracy, making it a common choice for many power tool accessory manufacturers.

Comparison of performance of zinc alloy with other die-casting materials

| Material | Dimensional Accuracy | Mold Life | Forming Complexity | Raw Material Cost | Density |

|---|---|---|---|---|---|

| Zinc Alloy | High | Long | High | Medium | High |

| Aluminum Alloy | Medium | Medium | Medium | Medium | Medium |

| Magnesium Alloy | Medium | Short | Medium | High | Low |

Sustainability and recycling

Under the current trend of green manufacturing, the recyclability of materials has become an important indicator of concern for enterprises. Zinc alloy has a high recycling rate, and the performance after regeneration remains stable, which is suitable for secondary die-casting production. By establishing an effective recycling system, manufacturers can reduce material waste, reduce environmental burden, and reduce production costs. In addition, scraps and unqualified products generated during the die-casting process can also be re-melted and reused to further improve resource utilization efficiency. This recycling feature enables zinc alloy to meet environmental protection requirements while also enhancing the competitiveness of enterprises.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский