How to ensure the dimensional stability of aluminum extrusion products?

24-07-2025Basic Concept of Dimensional Stability

The dimensional stability of aluminum extrusion products refers to the ability of aluminum profiles to maintain their dimensions within their design tolerances during forming, cooling, transportation, storage and use. This feature is critical for industrial applications that require high-precision connections, assembly or sealing. Dimensional deviations may lead to assembly difficulties, reduced strength or even functional failure, so multiple influencing factors must be comprehensively controlled in the design and manufacturing process.

The influence of alloy selection on dimensional stability

The alloy composition directly determines the degree of thermal deformation, cooling shrinkage rate and residual thermal stress of aluminum during extrusion. Commonly used 6000 series alloys (such as 6061 and 6063) are widely used in products with high requirements for dimensional stability due to their good processing performance and high thermal stability. In contrast, some 7000 series alloys with higher strength are prone to deformation after hot working, and additional cooling control and post-processing are required when used.

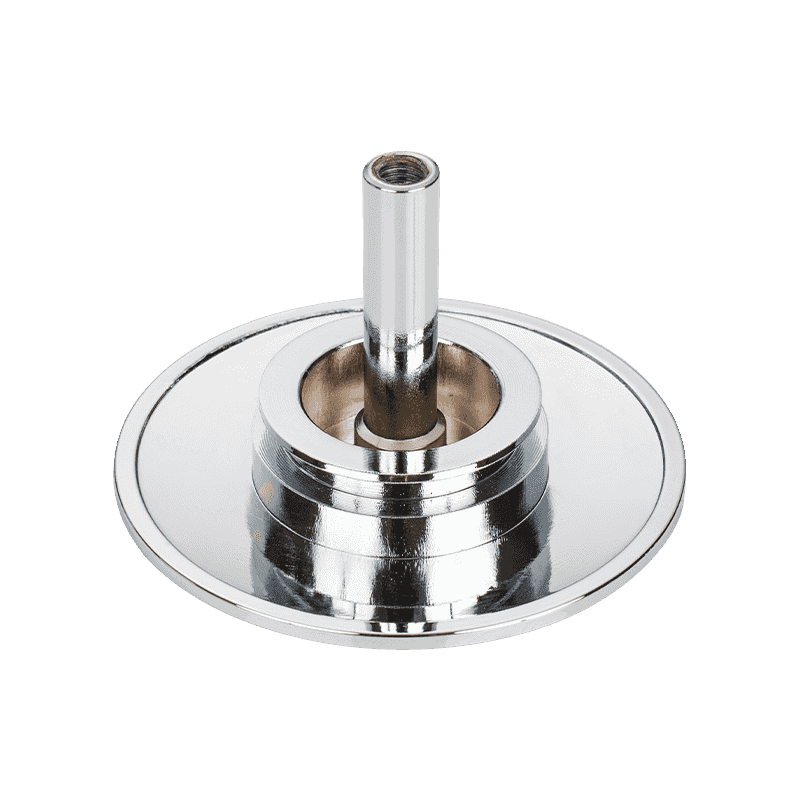

Precision and design of extrusion dies

The extrusion die is a direct tool for determining the cross-sectional shape and dimensional accuracy of the product. If the die has processing errors, thermal deformation or loose assembly, it is easy to cause local dimensional loss of control during the extrusion process. To ensure the accuracy of the mold, CNC machining technology is required, and heat treatment and rigid reinforcement are performed according to the use characteristics of the mold at high temperatures. In addition, the mold flow channel design must also be reasonable to avoid uneven metal flow causing profile deformation.

Optimization of extrusion process parameters

The control of extrusion temperature, speed and pressure is a key factor affecting dimensional stability. Excessive extrusion temperature can easily lead to excessive plastic flow of metal, making it difficult to control the size; excessive extrusion speed may cause problems such as "banana bend" or end deformation. Therefore, it is necessary to reasonably set the extruder parameters according to the aluminum alloy model and product shape, and use the data monitoring system to keep the process stable. In addition, adjusting the extrusion direction and feeding angle can also help reduce the lateral deformation of the profile.

The role of cooling and straightening process

Aluminum profiles need to be cooled immediately after demolding to avoid bending or twisting caused by excessive thermal stress. Common cooling methods include air cooling, water mist cooling or water tank cooling, and different methods are suitable for products of different thicknesses and cross-sectional shapes. After cooling, straightening treatment is required, and the possible minor deformation is adjusted to within the tolerance range through mechanical straightening equipment. If the cooling is uneven or the straightening angle is improperly controlled, it may be counterproductive and cause dimensional deviation.

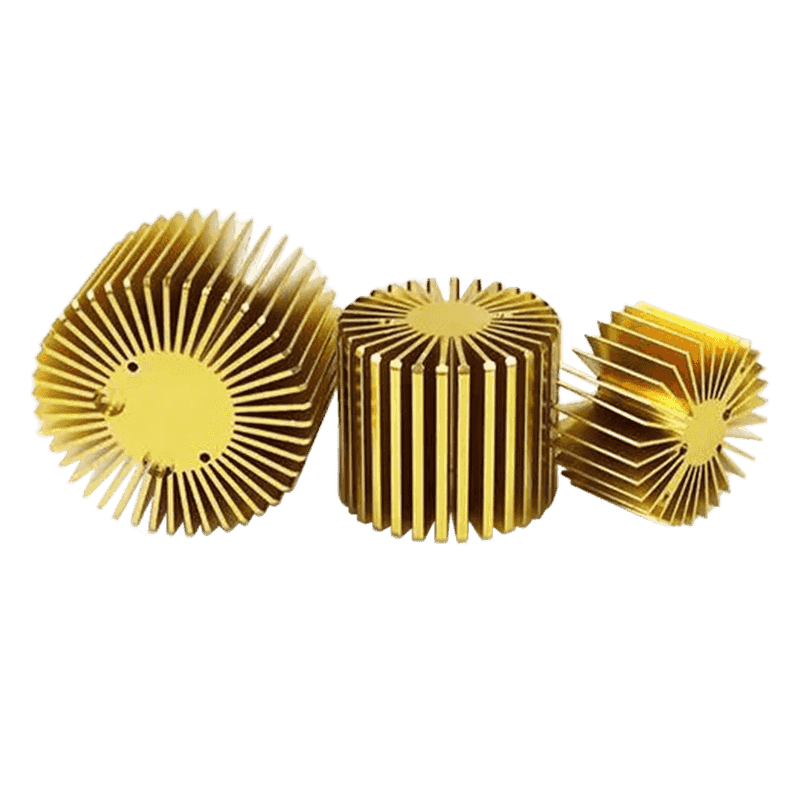

Aging treatment supplements stability

For aluminum extrusion products that need to enhance strength and structural stability, artificial aging or natural aging treatment is usually arranged. Artificial aging controls temperature and time to promote the formation of a stable structure of precipitates inside the metal crystal, thereby improving dimensional stability and mechanical properties. It should be noted that if the temperature is too high or the time is too long during the aging process, it will also cause dimensional changes, so standard process parameters should be used.

Control of storage and environmental factors

Aluminum profiles are sensitive to changes in the external environment. Temperature differences, humidity and storage stress will have a certain impact on their dimensions. During transportation and storage, it should be avoided that the extrusions are stacked too heavy or deformed by moisture. Reasonable use of brackets, cushions and ventilation equipment can effectively reduce geometric dimensional deviations caused by external forces or thermal expansion and contraction.

Inspection and quality control process

Dimension inspection is a direct means of evaluating stability. Calipers, three-coordinate measuring instruments, profile projectors and other tools are usually used to conduct random inspections of length, thickness, flatness, etc. To ensure data accuracy, the test needs to be carried out in a constant temperature room to avoid thermal expansion and contraction affecting the measurement results. At the same time, the implementation of first piece inspection, patrol inspection and final inspection during the extrusion production process can effectively detect and correct dimensional deviations in a timely manner.

Comparison table of the impact of different factors on dimensional stability

| Factor | Specific Manifestation | Impact Level on Dimensional Stability | Control Method |

|---|---|---|---|

| Alloy Type | Different alloy series have varying thermal behavior | Medium | Choose alloys with good processability and thermal stability (e.g., 6063) |

| Die Accuracy | Die wear or deviation causes inconsistent profiles | High | Use CNC-machined precision dies and maintain them regularly |

| Extrusion Temperature & Speed | High temperature or unstable speed causes uneven flow | High | Optimize temperature and speed using automated control systems |

| Cooling Method & Intensity | Uneven cooling leads to thermal stress and deformation | High | Select appropriate cooling methods and ensure uniform cooling |

| Aging Treatment | Improper temperature control causes size change | Medium | Strictly follow artificial or natural aging processes |

| Storage & Handling | Stacking pressure or environmental temperature shifts affect size | Low to Medium | Use racks for layered storage and avoid moisture or thermal shock |

| Inspection Procedure | Delayed or infrequent inspection | Medium | Enhance first-piece and final inspection; introduce in-line monitoring if needed |

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский