How to improve the efficiency and reduce costs of aluminum die casting production?

11-08-2025Process Optimization Improves Production Efficiency

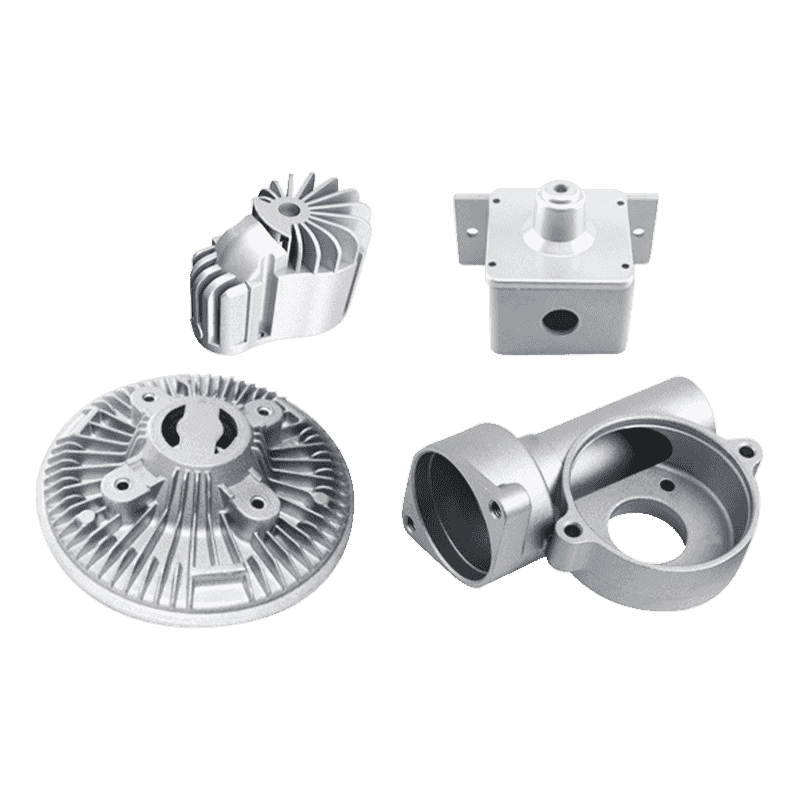

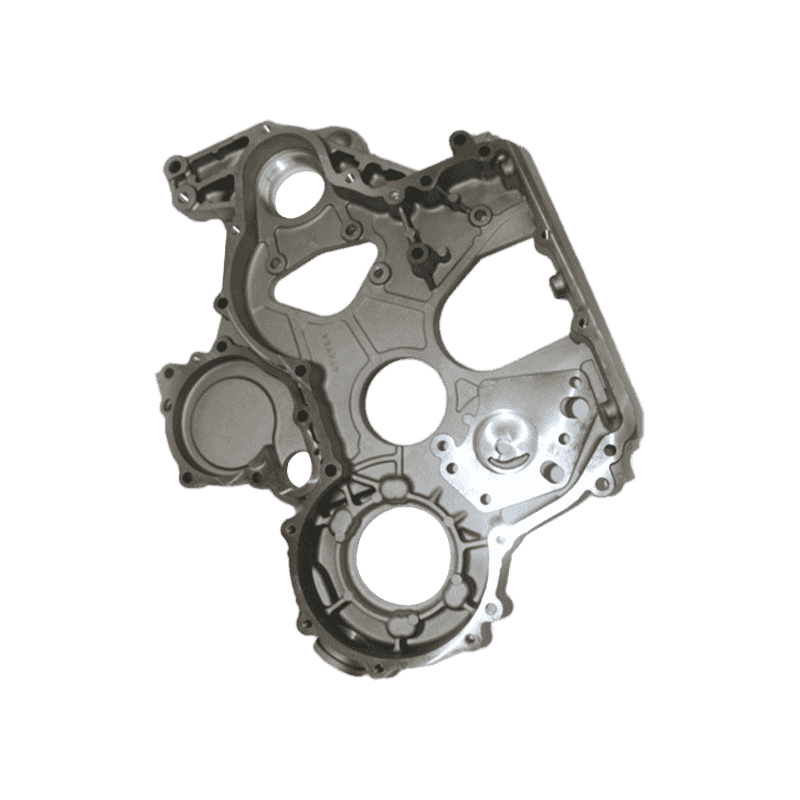

Aluminum die-casting production efficiency is closely related to the process flow. Reasonable process design can shorten production cycle time, reduce energy consumption, and increase single-piece production speed. First, a well-designed mold structure and runner system can help shorten injection and cooling times, thereby increasing unit production speed. Optimizing mold venting and cooling systems can reduce defects and lower rework costs. Second, adjusting process parameters such as injection speed, holding time, and pouring temperature ensures uniform metal flow, reduces defects such as porosity and shrinkage, improves first-pass yield, and reduces material loss. Computer simulation technology can assist in process design by proactively identifying potential problems and saving time on mold trials and commissioning.

Equipment Management and Maintenance Ensure Stable Production

Equipment performance and stability significantly impact production efficiency. Through effective equipment management and maintenance, equipment downtime can be reduced, ensuring continuous production. Regularly inspect and maintain the die-casting machine's hydraulic, heating, and control systems to ensure optimal operation. Introducing automated and intelligent equipment, using sensors and control systems to monitor production status in real time, enables fault warnings and remote diagnosis, reduces manual intervention, and improves equipment utilization. Rationally arrange production plans to avoid overuse or idle equipment, thereby increasing overall production capacity.

Material Utilization and Cost Control

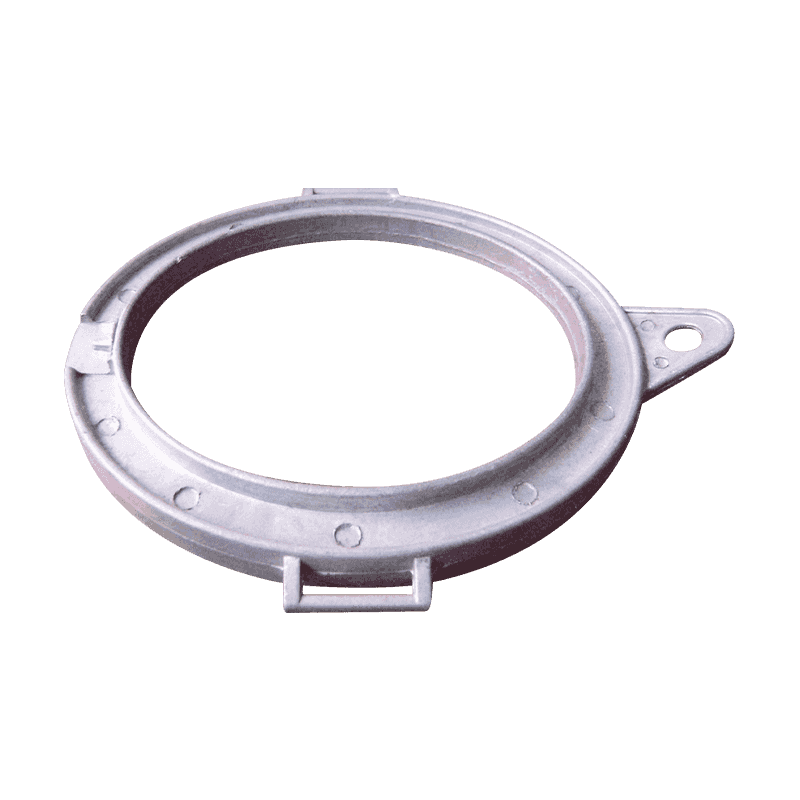

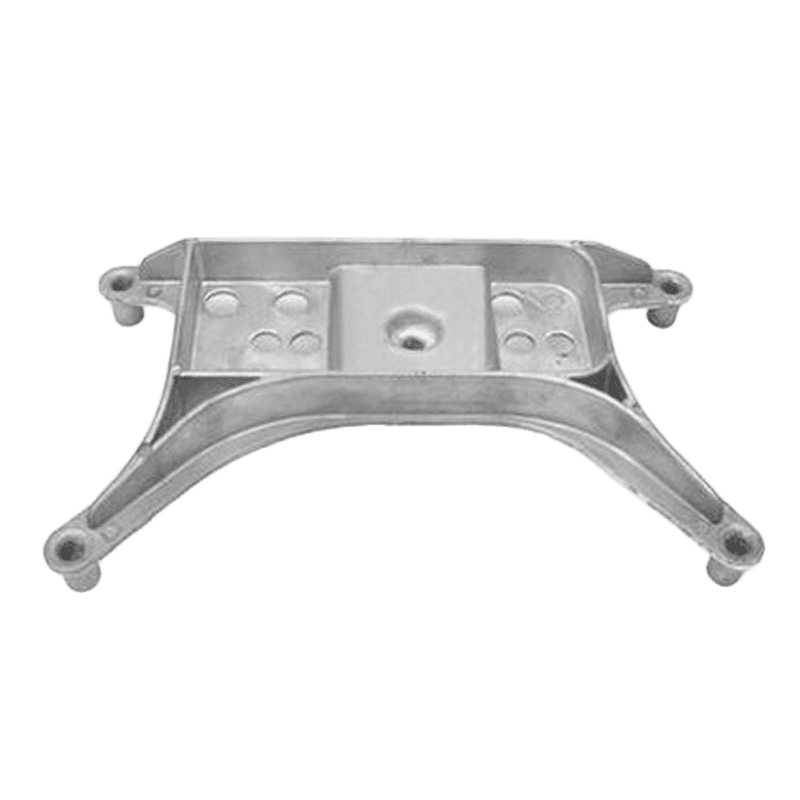

Aluminum die-casting material costs account for a significant proportion of overall costs, making rational material utilization a key approach to reducing costs. First, select the appropriate aluminum alloy, balancing cost and performance requirements, to avoid overdesign that leads to material waste. Second, optimize the heating and holding processes for the molten aluminum to minimize oxidation losses and inclusions during the smelting process, thereby lowering scrap rates. The design of aluminum die-cast parts should also consider reducing material usage, such as adopting appropriate wall thicknesses and lightweight structures to reduce molten aluminum usage. Establishing a scrap recycling and reuse system can effectively reduce material procurement costs while also minimizing environmental impact.

| Material Utilization Measures | Specific Actions |

|---|---|

| Reasonable Alloy Selection | Choose appropriate alloy types based on performance and cost |

| Optimized Melting Process | Control heating temperature and time to reduce oxidation and impurities |

| Structural Design Optimization | Use proper wall thickness and lightweight design to reduce material use |

| Waste Recycling and Reuse | Establish waste recycling systems to improve aluminum recovery and utilization |

Quality Control Reduces Rework and Scrap Rates

Quality issues directly impact production costs and efficiency. Strengthening process quality control can effectively reduce rework and scrap rates. First, strictly enforce incoming material inspection standards to ensure consistent raw material quality. Second, ensure that process parameters remain stable within control ranges. Use online testing equipment to monitor key parameters and product quality in real time, allowing for timely process adjustments. Conduct root cause analysis for common defects such as porosity and cracks, and implement targeted measures to reduce their occurrence. Improve employee training to enhance operational skills and quality awareness. Through continuous quality improvement activities, reduce defective product rates and save rework time and material costs.

Management Strategies And Personnel Training Promote Continuous Improvement

Production management quality is directly related to efficiency and cost control. Establish a scientific production management system encompassing production planning, materials management, equipment maintenance, and quality management to ensure coordinated operation of all aspects. Implement an information management system to enable real-time collection and analysis of production data, assist in decision-making, and improve responsiveness. Prioritize employee training to enhance their understanding and implementation of processes, equipment, and quality requirements, thereby improving production efficiency. Encourage team communication and collaboration to promptly resolve production issues and drive continuous improvement. Improve performance appraisal mechanisms to motivate employees to actively participate in efficiency and cost improvement activities.

| Management Strategy | Implementation Measures |

|---|---|

| Production Planning | Develop reasonable production plans and coordinate equipment and personnel resources |

| Information Management | Introduce MES and other systems for data collection and analysis |

| Employee Training | Conduct regular training on processes, equipment operation, and quality standards |

| Team Communication | Establish communication platforms to promptly address production issues |

| Performance Evaluation | Set up incentive mechanisms to encourage efficiency and cost improvements |

Improve Production Efficiency Through The Application Of Automation Technology

With the development of Industry 4.0, the aluminum die-casting industry is gradually introducing automated equipment to improve production efficiency and reduce labor costs. Automatic loading and unloading manipulators and robots enable rapid mold loading and unloading, reducing operator time and improving production cycle stability. Automated inspection equipment can also monitor product dimensions, defects, and weight online, promptly identifying anomalies and preventing defective products from entering downstream processes. Automation can also reduce quality issues caused by human error, improving overall production continuity and stability.

Green Production Concepts Reduce Cost Pressures

Green production not only contributes to environmental protection but also reduces operating costs in the long term. Aluminum die-casting consumes significant energy. Using energy-efficient equipment and optimizing energy management can help reduce energy costs. For example, using energy-efficient furnaces and heating equipment and rationally scheduling production shifts to minimize idle operations can significantly reduce electricity and fuel consumption. Furthermore, environmentally friendly measures such as exhaust gas recovery and waste material reuse not only comply with environmental regulations, but also reduce resource waste and overall operating costs.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский