What are the differences and characteristics of lead die casting and other metal die casting?

19-08-2025Basic Characteristics of Lead Die Casting

Lead die casting uses lead and its alloys as raw materials. Molten metal is injected into a mold cavity under high pressure to create a desired metal product. Lead has a low melting point, generally around 327°C, so the process temperature for lead die casting is low, effectively reducing energy consumption. Lead has a high density, resulting in heavier finished products, making it suitable for manufacturing parts requiring high density and wear resistance. Furthermore, lead exhibits excellent corrosion resistance, especially in certain environments, exhibiting good chemical stability. The lead die casting process, which includes melting, injection, cooling, demolding, and post-processing, is relatively mature and can be highly automated.

Main Differences Between Lead and Aluminum Die Casting

Lead die casting and aluminum die casting are two common metal die casting processes, but they differ in material properties, process parameters, and application areas. Aluminum alloys have a higher melting point, generally above 660°C, and injection temperatures are higher than those for lead die casting, resulting in higher energy consumption and equipment requirements. Aluminum die castings are lightweight, making them suitable for manufacturing parts requiring lightweighting. In comparison, lead die-castings have a higher density and are suitable for applications requiring higher quality and wear resistance. Aluminum alloys offer higher strength after forming and excellent thermal conductivity and heat dissipation, while lead alloys are more suitable for products requiring good sealing and barrier properties. The two also differ in mold design and process control; lead die-casting molds are subject to relatively lower temperatures and pressures.

Comparison of Lead Die-Casting and Zinc Die-Casting

Zinc die-casting is commonly used to manufacture small, complex, and high-precision parts. Zinc has a melting point of approximately 419°C, intermediate between lead and aluminum. Zinc die-castings offer superior mechanical properties and surface finish, and are easy to process. Compared to lead die-casting, zinc die-castings are generally harder and stronger, but with lower density and weight. Zinc die-casting is suitable for products requiring a refined appearance and complex structures, such as electronic component housings and precision instrument components. Lead die-casting, due to its higher density and better corrosion resistance, is often used in specialized applications requiring radiation protection or wear resistance. The two also have different requirements regarding environmental safety and health management. Lead is highly toxic, requiring strict control over production and use environments.

Lead Die-Casting Advantages and Limitations

The advantages of lead die-casting primarily lie in the energy savings achieved by its low melting point, as well as the material's inherent high density and corrosion resistance. These characteristics make lead die-casting suitable for the manufacture of specialized components, such as radiation shielding equipment and wear-resistant parts. Furthermore, lead die-casting requires lower mold pressure and temperature, which helps extend mold life and reduce equipment maintenance costs. However, lead's toxicity and environmental restrictions are major limitations of this process, requiring strict emission controls and worker safety measures. Furthermore, the mechanical properties of lead die-casting parts are limited compared to those of aluminum and zinc die-casting parts, limiting their use in high-strength applications.

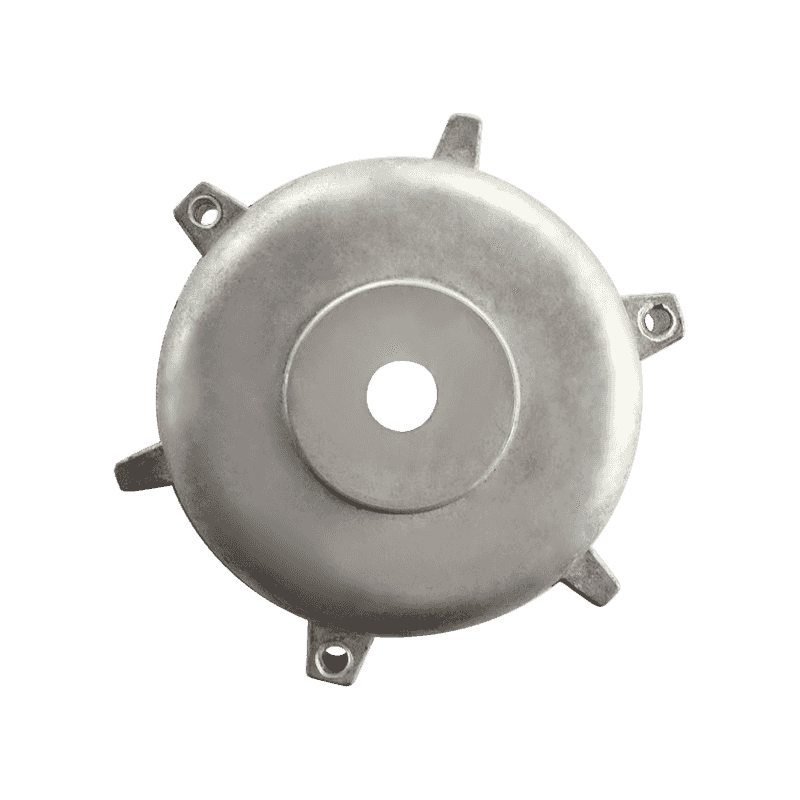

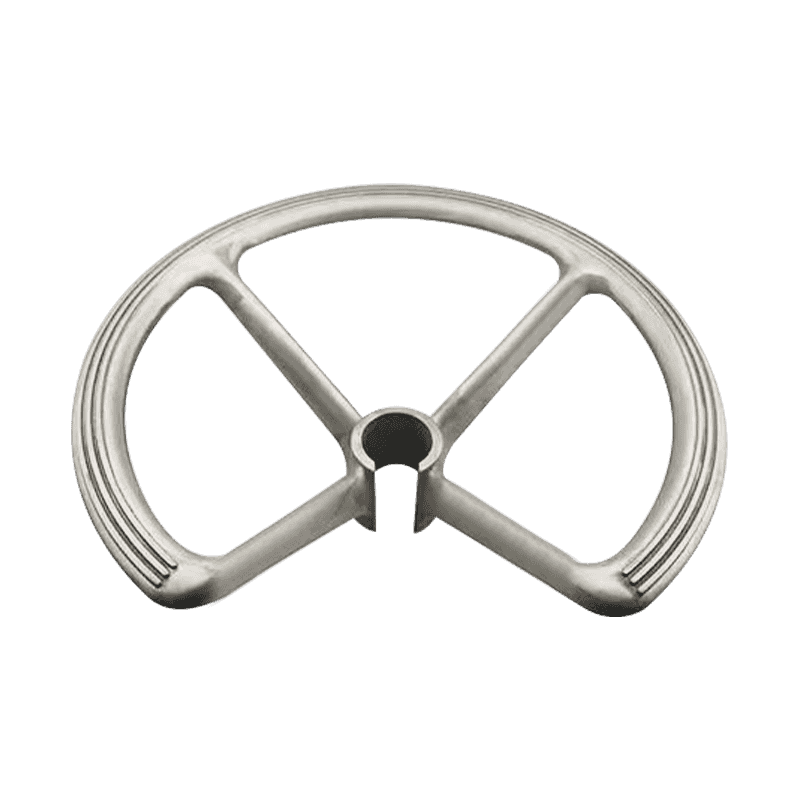

Lead Die-Casting Application Analysis

Lead die-casting is primarily used in the manufacture of components requiring high density, corrosion resistance, and radiation protection, such as battery components, protective covers, radiation shielding devices, and some mechanical seals. In these applications, lead die-casting offers advantages in sealing, wear resistance, and barrier properties. Compared to aluminum and zinc die-casting, lead die-casting offers advantages in terms of weight and protection, but its application is limited in applications requiring lightweight design. With increasingly stringent environmental regulations, the application scope of lead die-casting has been limited. Companies must balance material properties with environmental compliance in actual production.

Environmental and Health and Safety Considerations

The toxicity of lead materials poses potential risks to the environment and human health. Effective measures must be taken during lead die-casting production to control lead dust and exhaust emissions and avoid lead pollution. Workshop ventilation, exhaust gas purification systems, and personal protective equipment are key to worker safety. Companies must strictly comply with relevant environmental protection regulations and regularly monitor emissions to ensure that production processes meet environmental standards. Furthermore, the recycling and disposal of waste lead materials must be regulated to prevent secondary pollution. Environmental requirements are driving companies to explore alternative materials and technologies in lead die-casting processes to reduce environmental pressure.

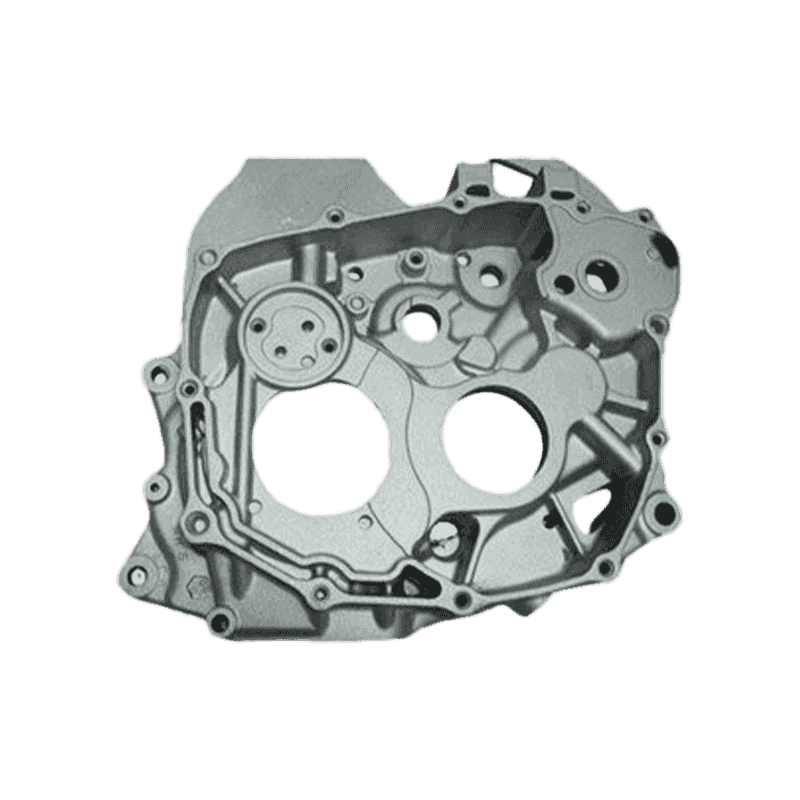

Features of Lead Die-Casting Equipment and Molds

Compared to aluminum die-casting equipment, lead die-casting equipment has lower requirements for high-temperature and pressure resistance, a relatively simple structure, and lower maintenance costs. Mold materials are typically steel with good wear resistance, but due to the lower temperatures, mold thermal fatigue is less likely to occur. Mold design must consider the flow and shrinkage characteristics of the lead alloy to ensure dimensional accuracy of the casting. Lead die-casting offers a relatively long mold life, enabling it to support large-volume production. Appropriate mold design helps reduce casting defects and improve product quality.

Comparing the Economic Efficiency of Lead Die-Casting with Other Die-Casting Processes

The production cost of lead die-casting is influenced by factors such as material price, equipment investment, and environmental protection efforts. While lead material prices are relatively stable, environmental protection and protective measures incur additional costs. Compared to aluminum die-casting, lead die-casting consumes less energy, requires less equipment investment, and requires less maintenance. However, the handling and disposal of lead materials incurs a higher cost burden. Zinc die-casting, however, has a relatively high unit cost due to its superior mechanical properties and added value. Companies should consider the economic feasibility of various die-casting processes based on product demand and market conditions to select the appropriate production method.

| Comparison Aspect | Lead Die Casting | Aluminum Die Casting | Zinc Die Casting |

|---|---|---|---|

| Melting Point (°C) | ~327 | ~660 | ~419 |

| Density (g/cm³) | High (11.34) | Low (2.7) | Medium (7.14) |

| Typical Applications | Radiation shielding, heavy parts | Lightweight automotive parts | Precision components |

| Environmental Risk | High due to toxicity | Moderate | Moderate |

| Equipment Demand | Lower temperature and pressure | Higher temperature and pressure | Medium temperature and pressure |

| Cost Factors | Lower energy cost, higher disposal cost | Higher energy cost, moderate disposal | Moderate energy and disposal costs |

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский