In the auto world, not everything that moves is loud. Sometimes the biggest changes come from something you barely notice, like the parts inside the e...

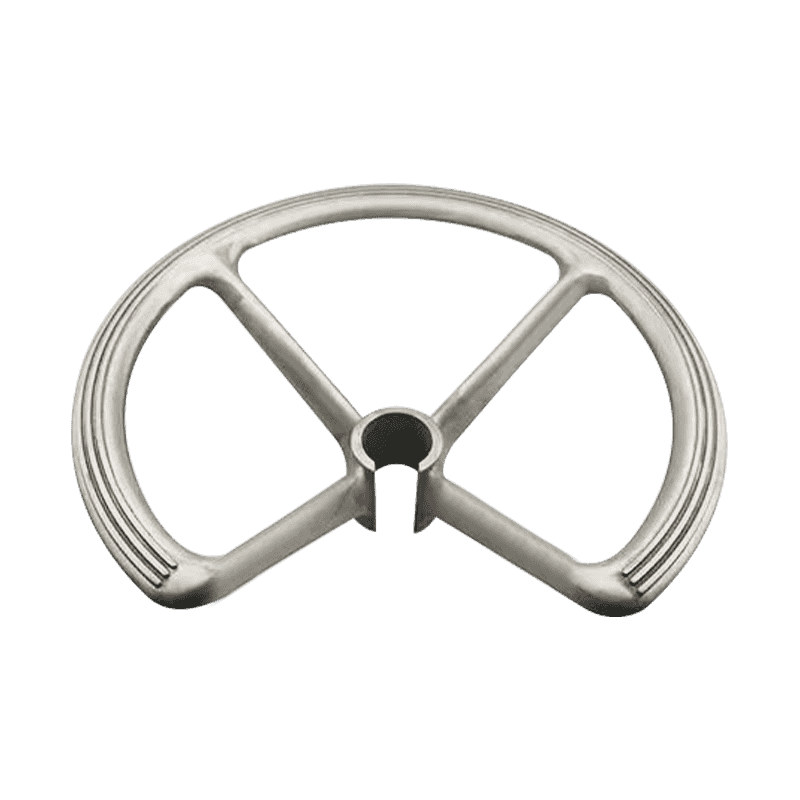

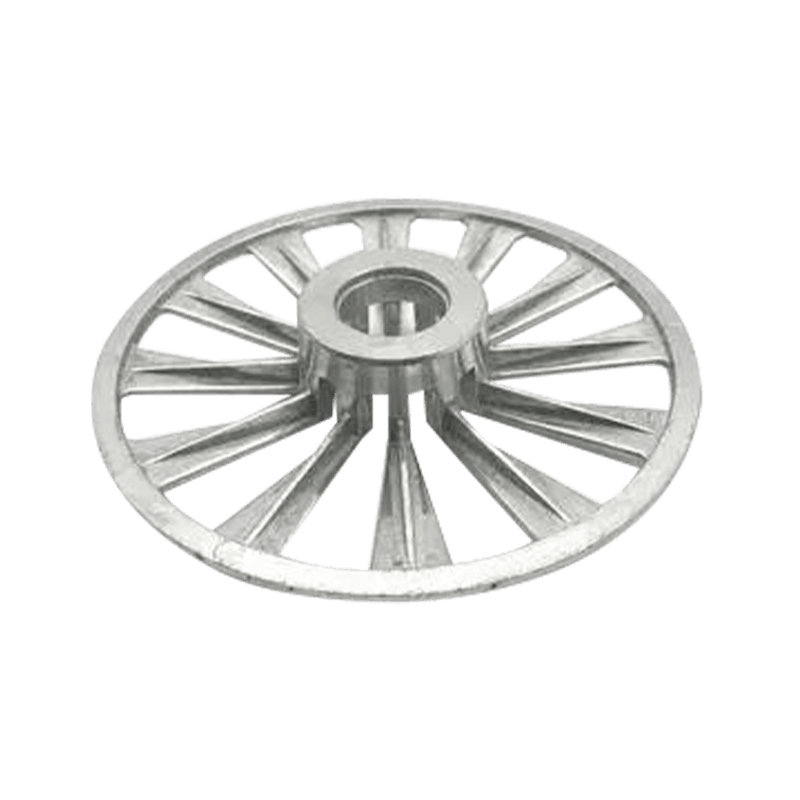

Read MoreCustom Die Casting Parts Manufacturers

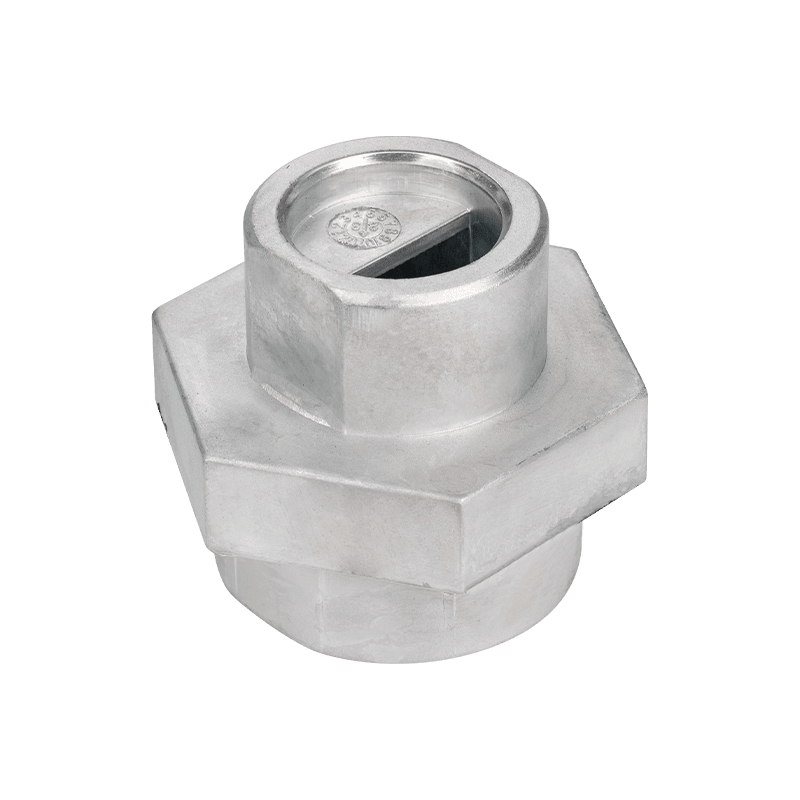

| 1. Drawings or Samples | We get the drawings or samples from customers. |

| 2. Drawings Confirmation | We will draw the 3D drawings according to the customers' 2D drawings or samples, and send the 3D drawings to customers for confirmation. |

| 3. Quotation | We will quote after getting the customers' confirmation, or quote directly according to customers' 3D drawings. |

| 4. Making Moulds/Patterns | We will make molds or pattens after getting the mold orders from the customers. |

| 5. Making Samples | We will make real samples using the molds and send them to customers for confirmation. |

| 6. Mass Producing | We will produce the products after getting the customers' confirmation and orders. |

| 7. Inspection | We will inspect the products by our inspectors or ask the customers to inspect together with us when finished. |

| 8. Shipment | We will ship the goods to the customers after getting the inspection result and the customers' confirmation. |

| Process: | 1) Die Casting / Profile Extrusion |

| 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading | |

| 3) Surface Treating | |

| 4) Inspection and Packaging | |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. |

| 2) Aluminum Alloys Profile Extrusion: 6061, 6063 | |

| 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. | |

| Surface Treatment: | Polishing |

| Shot Blasting | |

| Sandblasting | |

| Powder Coating | |

| Anodizing | |

| Chrome Plating | |

| Passivation | |

| E-coating | |

| T-coating | |

| etc. | |

| Tolerance: | +/-0.01mm |

| Weight Per Unit: | 0.01-5KG |

| Order Lead Time: | 20-45 Days (According to the Quantity and Complexity of the Product 1 |

| 1. Drawings or Samples | We get the drawings or samples from customers. |

| 2. Drawings Confirmation | We will draw the 3D drawings according to the customers' 2D drawings or samples, and send the 3D drawings to customers for confirmation. |

| 3. Quotation | We will quote after getting the customers' confirmation, or quote directly according to customers' 3D drawings. |

| 4. Making Moulds/Patterns | We will make molds or pattens after getting the mold orders from the customers. |

| 5. Making Samples | We will make real samples using the molds and send them to customers for confirmation. |

| 6. Mass Producing | We will produce the products after getting the customers' confirmation and orders. |

| 7. Inspection | We will inspect the products by our inspectors or ask the customers to inspect together with us when finished. |

| 8. Shipment | We will ship the goods to the customers after getting the inspection result and the customers' confirmation. |

| Process: | 1) Die Casting / Profile Extrusion |

| 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading | |

| 3) Surface Treating | |

| 4) Inspection and Packaging | |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. |

| 2) Aluminum Alloys Profile Extrusion: 6061, 6063 | |

| 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. | |

| Surface Treatment: | Polishing |

| Shot Blasting | |

| Sandblasting | |

| Powder Coating | |

| Anodizing | |

| Chrome Plating | |

| Passivation | |

| E-coating | |

| T-coating | |

| etc. | |

| Tolerance: | +/-0.01mm |

| Weight Per Unit: | 0.01-5KG |

| Order Lead Time: | 20-45 Days (According to the Quantity and Complexity of the Product 1 |

| 1. Drawings or Samples | We get the drawings or samples from customers. |

| 2. Drawings Confirmation | We will draw the 3D drawings according to the customers' 2D drawings or samples, and send the 3D drawings to customers for confirmation. |

| 3. Quotation | We will quote after getting the customers' confirmation, or quote directly according to customers' 3D drawings. |

| 4. Making Moulds/Patterns | We will make molds or pattens after getting the mold orders from the customers. |

| 5. Making Samples | We will make real samples using the molds and send them to customers for confirmation. |

| 6. Mass Producing | We will produce the products after getting the customers' confirmation and orders. |

| 7. Inspection | We will inspect the products by our inspectors or ask the customers to inspect together with us when finished. |

| 8. Shipment | We will ship the goods to the customers after getting the inspection result and the customers' confirmation. |

| Process: | 1) Die Casting / Profile Extrusion |

| 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading | |

| 3) Surface Treating | |

| 4) Inspection and Packaging | |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. |

| 2) Aluminum Alloys Profile Extrusion: 6061, 6063 | |

| 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. | |

| Surface Treatment: | Polishing |

| Shot Blasting | |

| Sandblasting | |

| Powder Coating | |

| Anodizing | |

| Chrome Plating | |

| Passivation | |

| E-coating | |

| T-coating | |

| etc. | |

| Tolerance: | +/-0.01mm |

| Weight Per Unit: | 0.01-5KG |

| Order Lead Time: | 20-45 Days (According to the Quantity and Complexity of the Product 1 |

| 1. Drawings or Samples | We get the drawings or samples from customers. |

| 2. Drawings Confirmation | We will draw the 3D drawings according to the customers' 2D drawings or samples, and send the 3D drawings to customers for confirmation. |

| 3. Quotation | We will quote after getting the customers' confirmation, or quote directly according to customers' 3D drawings. |

| 4. Making Moulds/Patterns | We will make molds or pattens after getting the mold orders from the customers. |

| 5. Making Samples | We will make real samples using the molds and send them to customers for confirmation. |

| 6. Mass Producing | We will produce the products after getting the customers' confirmation and orders. |

| 7. Inspection | We will inspect the products by our inspectors or ask the customers to inspect together with us when finished. |

| 8. Shipment | We will ship the goods to the customers after getting the inspection result and the customers' confirmation. |

| Process: | 1) Die Casting / Profile Extrusion |

| 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading | |

| 3) Surface Treating | |

| 4) Inspection and Packaging | |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. |

| 2) Aluminum Alloys Profile Extrusion: 6061, 6063 | |

| 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. | |

| Surface Treatment: | Polishing |

| Shot Blasting | |

| Sandblasting | |

| Powder Coating | |

| Anodizing | |

| Chrome Plating | |

| Passivation | |

| E-coating | |

| T-coating | |

| etc. | |

| Tolerance: | +/-0.01mm |

| Weight Per Unit: | 0.01-5KG |

| Order Lead Time: | 20-45 Days (According to the Quantity and Complexity of the Product 1 |

| 1. Drawings or Samples | We get the drawings or samples from customers. |

| 2. Drawings Confirmation | We will draw the 3D drawings according to the customers' 2D drawings or samples, and send the 3D drawings to customers for confirmation. |

| 3. Quotation | We will quote after getting the customers' confirmation, or quote directly according to customers' 3D drawings. |

| 4. Making Moulds/Patterns | We will make molds or pattens after getting the mold orders from the customers. |

| 5. Making Samples | We will make real samples using the molds and send them to customers for confirmation. |

| 6. Mass Producing | We will produce the products after getting the customers' confirmation and orders. |

| 7. Inspection | We will inspect the products by our inspectors or ask the customers to inspect together with us when finished. |

| 8. Shipment | We will ship the goods to the customers after getting the inspection result and the customers' confirmation. |

| Process: | 1) Die Casting / Profile Extrusion |

| 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading | |

| 3) Surface Treating | |

| 4) Inspection and Packaging | |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. |

| 2) Aluminum Alloys Profile Extrusion: 6061, 6063 | |

| 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. | |

| Surface Treatment: | Polishing |

| Shot Blasting | |

| Sandblasting | |

| Powder Coating | |

| Anodizing | |

| Chrome Plating | |

| Passivation | |

| E-coating | |

| T-coating | |

| etc. | |

| Tolerance: | +/-0.01mm |

| Weight Per Unit: | 0.01-5KG |

| Order Lead Time: | 20-45 Days (According to the Quantity and Complexity of the Product 1 |

| 1. Drawings or Samples | We get the drawings or samples from customers. |

| 2. Drawings Confirmation | We will draw the 3D drawings according to the customers' 2D drawings or samples, and send the 3D drawings to customers for confirmation. |

| 3. Quotation | We will quote after getting the customers' confirmation, or quote directly according to customers' 3D drawings. |

| 4. Making Moulds/Patterns | We will make molds or pattens after getting the mold orders from the customers. |

| 5. Making Samples | We will make real samples using the molds and send them to customers for confirmation. |

| 6. Mass Producing | We will produce the products after getting the customers' confirmation and orders. |

| 7. Inspection | We will inspect the products by our inspectors or ask the customers to inspect together with us when finished. |

| 8. Shipment | We will ship the goods to the customers after getting the inspection result and the customers' confirmation. |

| Process: | 1) Die Casting / Profile Extrusion |

| 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading | |

| 3) Surface Treating | |

| 4) Inspection and Packaging | |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. |

| 2) Aluminum Alloys Profile Extrusion: 6061, 6063 | |

| 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. | |

| Surface Treatment: | Polishing |

| Shot Blasting | |

| Sandblasting | |

| Powder Coating | |

| Anodizing | |

| Chrome Plating | |

| Passivation | |

| E-coating | |

| T-coating | |

| etc. | |

| Tolerance: | +/-0.01mm |

| Weight Per Unit: | 0.01-5KG |

| Order Lead Time: | 20-45 Days (According to the Quantity and Complexity of the Product 1 |

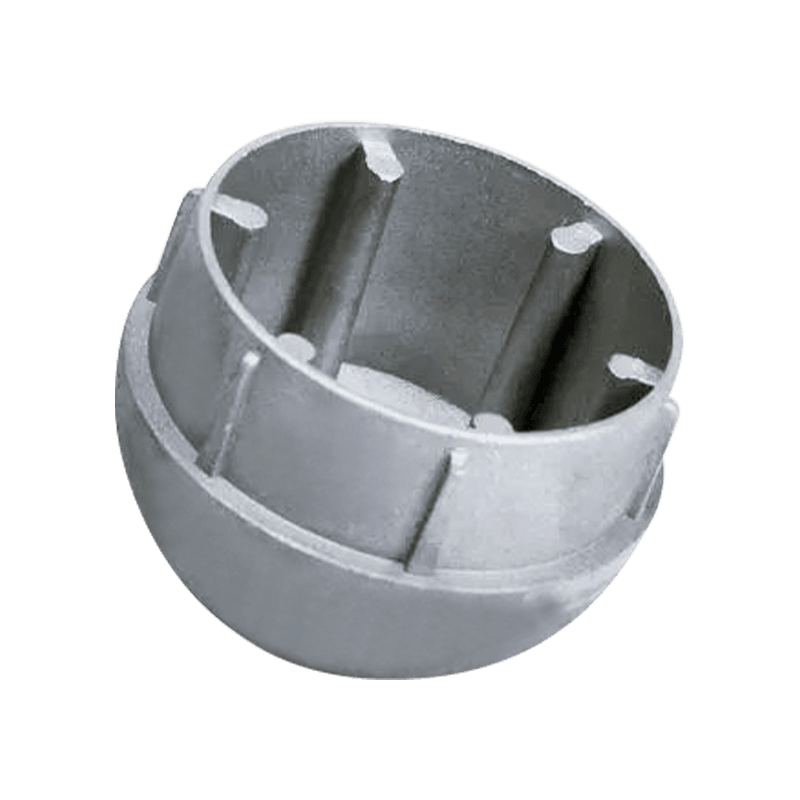

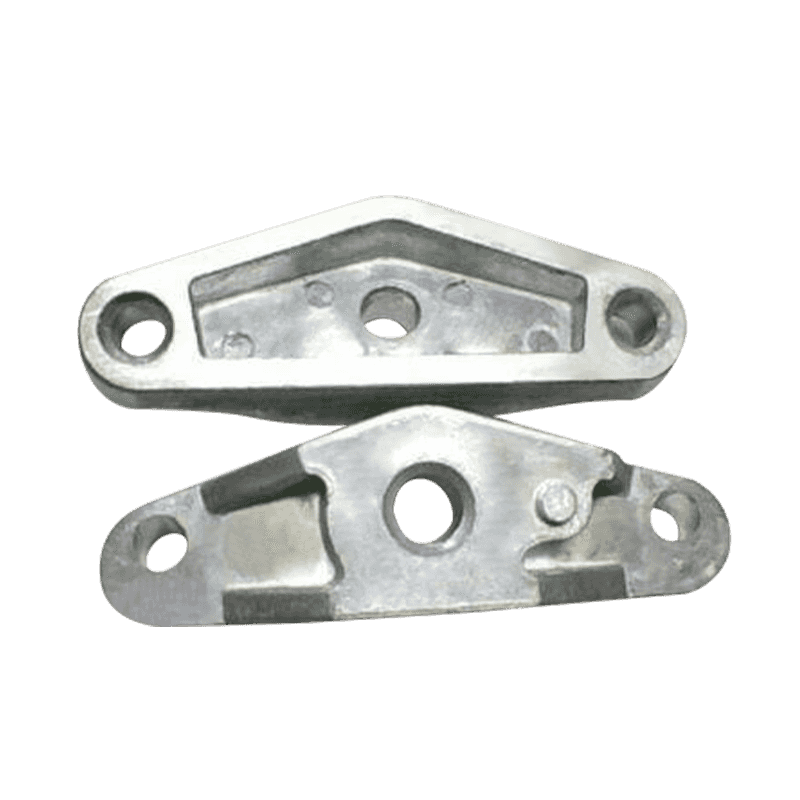

Zinc alloy power tool fittings

Zinc Alloy Electronic Product Connector Zinc Alloy Electronic Parts

| 1. Drawings or Samples | We get the drawings or samples from customers. |

| 2. Drawings Confirmation | We will draw the 3D drawings according to the customers' 2D drawings or samples, and send the 3D drawings to customers for confirmation. |

| 3. Quotation | We will quote after getting the customers' confirmation, or quote directly according to customers' 3D drawings. |

| 4. Making Moulds/Patterns | We will make molds or pattens after getting the mold orders from the customers. |

| 5. Making Samples | We will make real samples using the molds and send them to customers for confirmation. |

| 6. Mass Producing | We will produce the products after getting the customers' confirmation and orders. |

| 7. Inspection | We will inspect the products by our inspectors or ask the customers to inspect together with us when finished. |

| 8. Shipment | We will ship the goods to the customers after getting the inspection result and the customers' confirmation. |

| Process: | 1) Die Casting / Profile Extrusion |

| 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading | |

| 3) Surface Treating | |

| 4) Inspection and Packaging | |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. |

| 2) Aluminum Alloys Profile Extrusion: 6061, 6063 | |

| 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. | |

| Surface Treatment: | Polishing |

| Shot Blasting | |

| Sandblasting | |

| Powder Coating | |

| Anodizing | |

| Chrome Plating | |

| Passivation | |

| E-coating | |

| T-coating | |

| etc. | |

| Tolerance: | +/-0.01mm |

| Weight Per Unit: | 0.01-5KG |

| Order Lead Time: | 20-45 Days (According to the Quantity and Complexity of the Product 1 |

| 1. Drawings or Samples | We get the drawings or samples from customers. |

| 2. Drawings Confirmation | We will draw the 3D drawings according to the customers' 2D drawings or samples, and send the 3D drawings to customers for confirmation. |

| 3. Quotation | We will quote after getting the customers' confirmation, or quote directly according to customers' 3D drawings. |

| 4. Making Moulds/Patterns | We will make molds or pattens after getting the mold orders from the customers. |

| 5. Making Samples | We will make real samples using the molds and send them to customers for confirmation. |

| 6. Mass Producing | We will produce the products after getting the customers' confirmation and orders. |

| 7. Inspection | We will inspect the products by our inspectors or ask the customers to inspect together with us when finished. |

| 8. Shipment | We will ship the goods to the customers after getting the inspection result and the customers' confirmation. |

| Process: | 1) Die Casting / Profile Extrusion |

| 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading | |

| 3) Surface Treating | |

| 4) Inspection and Packaging | |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. |

| 2) Aluminum Alloys Profile Extrusion: 6061, 6063 | |

| 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. | |

| Surface Treatment: | Polishing |

| Shot Blasting | |

| Sandblasting | |

| Powder Coating | |

| Anodizing | |

| Chrome Plating | |

| Passivation | |

| E-coating | |

| T-coating | |

| etc. | |

| Tolerance: | +/-0.01mm |

| Weight Per Unit: | 0.01-5KG |

| Order Lead Time: | 20-45 Days (According to the Quantity and Complexity of the Product 1 |

| 1. Drawings or Samples | We get the drawings or samples from customers. |

| 2. Drawings Confirmation | We will draw the 3D drawings according to the customers' 2D drawings or samples, and send the 3D drawings to customers for confirmation. |

| 3. Quotation | We will quote after getting the customers' confirmation, or quote directly according to customers' 3D drawings. |

| 4. Making Moulds/Patterns | We will make molds or pattens after getting the mold orders from the customers. |

| 5. Making Samples | We will make real samples using the molds and send them to customers for confirmation. |

| 6. Mass Producing | We will produce the products after getting the customers' confirmation and orders. |

| 7. Inspection | We will inspect the products by our inspectors or ask the customers to inspect together with us when finished. |

| 8. Shipment | We will ship the goods to the customers after getting the inspection result and the customers' confirmation. |

| Process: | 1) Die Casting / Profile Extrusion |

| 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading | |

| 3) Surface Treating | |

| 4) Inspection and Packaging | |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. |

| 2) Aluminum Alloys Profile Extrusion: 6061, 6063 | |

| 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. | |

| Surface Treatment: | Polishing |

| Shot Blasting | |

| Sandblasting | |

| Powder Coating | |

| Anodizing | |

| Chrome Plating | |

| Passivation | |

| E-coating | |

| T-coating | |

| etc. | |

| Tolerance: | +/-0.01mm |

| Weight Per Unit: | 0.01-5KG |

| Order Lead Time: | 20-45 Days (According to the Quantity and Complexity of the Product 1 |

| 1. Drawings or Samples | We get the drawings or samples from customers. |

| 2. Drawings Confirmation | We will draw the 3D drawings according to the customers' 2D drawings or samples, and send the 3D drawings to customers for confirmation. |

| 3. Quotation | We will quote after getting the customers' confirmation, or quote directly according to customers' 3D drawings. |

| 4. Making Moulds/Patterns | We will make molds or pattens after getting the mold orders from the customers. |

| 5. Making Samples | We will make real samples using the molds and send them to customers for confirmation. |

| 6. Mass Producing | We will produce the products after getting the customers' confirmation and orders. |

| 7. Inspection | We will inspect the products by our inspectors or ask the customers to inspect together with us when finished. |

| 8. Shipment | We will ship the goods to the customers after getting the inspection result and the customers' confirmation. |

| Process: | 1) Die Casting / Profile Extrusion |

| 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading | |

| 3) Surface Treating | |

| 4) Inspection and Packaging | |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. |

| 2) Aluminum Alloys Profile Extrusion: 6061, 6063 | |

| 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. | |

| Surface Treatment: | Polishing |

| Shot Blasting | |

| Sandblasting | |

| Powder Coating | |

| Anodizing | |

| Chrome Plating | |

| Passivation | |

| E-coating | |

| T-coating | |

| etc. | |

| Tolerance: | +/-0.01mm |

| Weight Per Unit: | 0.01-5KG |

| Order Lead Time: | 20-45 Days (According to the Quantity and Complexity of the Product 1 |

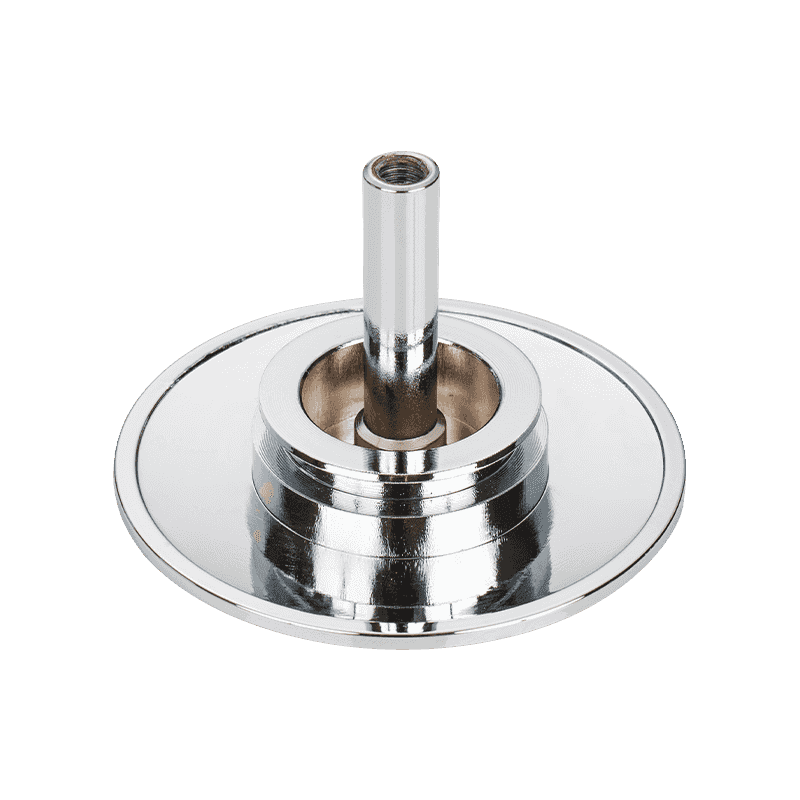

Zinc alloy electronic product fittings

Aluminium Alloy Electronic Product Connector Aluminium Alloy Electronic Product Parts

| 1. Drawings or Samples | We get the drawings or samples from customers. |

| 2. Drawings Confirmation | We will draw the 3D drawings according to the customers' 2D drawings or samples, and send the 3D drawings to customers for confirmation. |

| 3. Quotation | We will quote after getting the customers' confirmation, or quote directly according to customers' 3D drawings. |

| 4. Making Moulds/Patterns | We will make molds or pattens after getting the mold orders from the customers. |

| 5. Making Samples | We will make real samples using the molds and send them to customers for confirmation. |

| 6. Mass Producing | We will produce the products after getting the customers' confirmation and orders. |

| 7. Inspection | We will inspect the products by our inspectors or ask the customers to inspect together with us when finished. |

| 8. Shipment | We will ship the goods to the customers after getting the inspection result and the customers' confirmation. |

| Process: | 1) Die Casting / Profile Extrusion |

| 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading | |

| 3) Surface Treating | |

| 4) Inspection and Packaging | |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. |

| 2) Aluminum Alloys Profile Extrusion: 6061, 6063 | |

| 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. | |

| Surface Treatment: | Polishing |

| Shot Blasting | |

| Sandblasting | |

| Powder Coating | |

| Anodizing | |

| Chrome Plating | |

| Passivation | |

| E-coating | |

| T-coating | |

| etc. | |

| Tolerance: | +/-0.01mm |

| Weight Per Unit: | 0.01-5KG |

| Order Lead Time: | 20-45 Days (According to the Quantity and Complexity of the Product 1 |

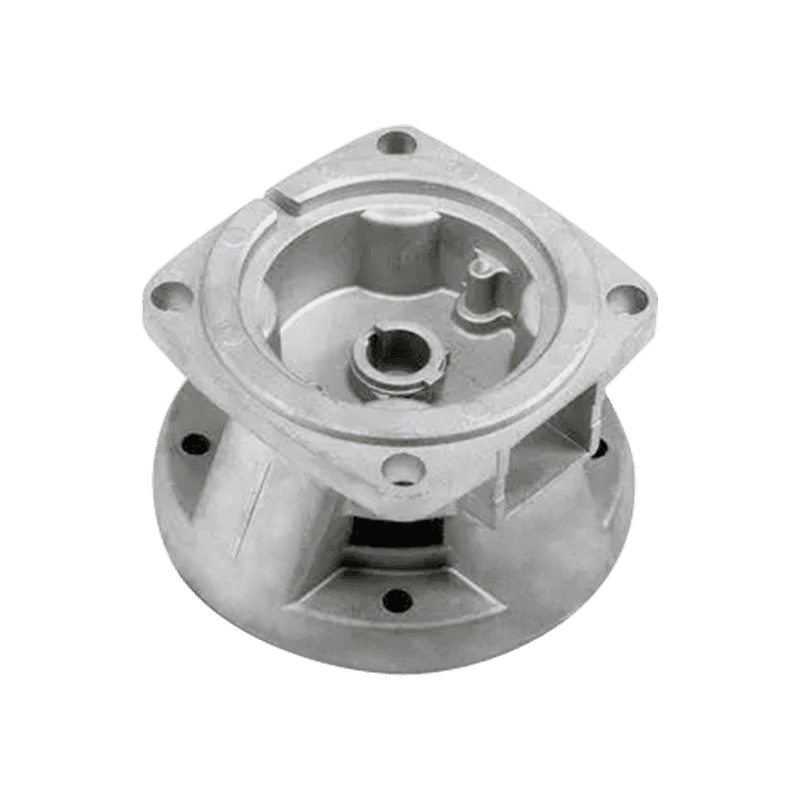

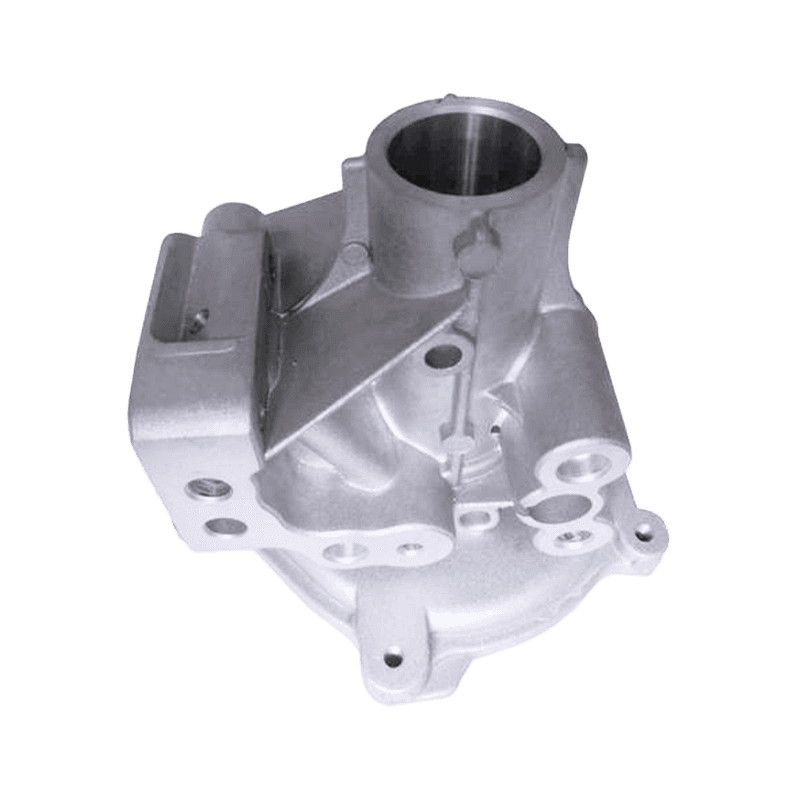

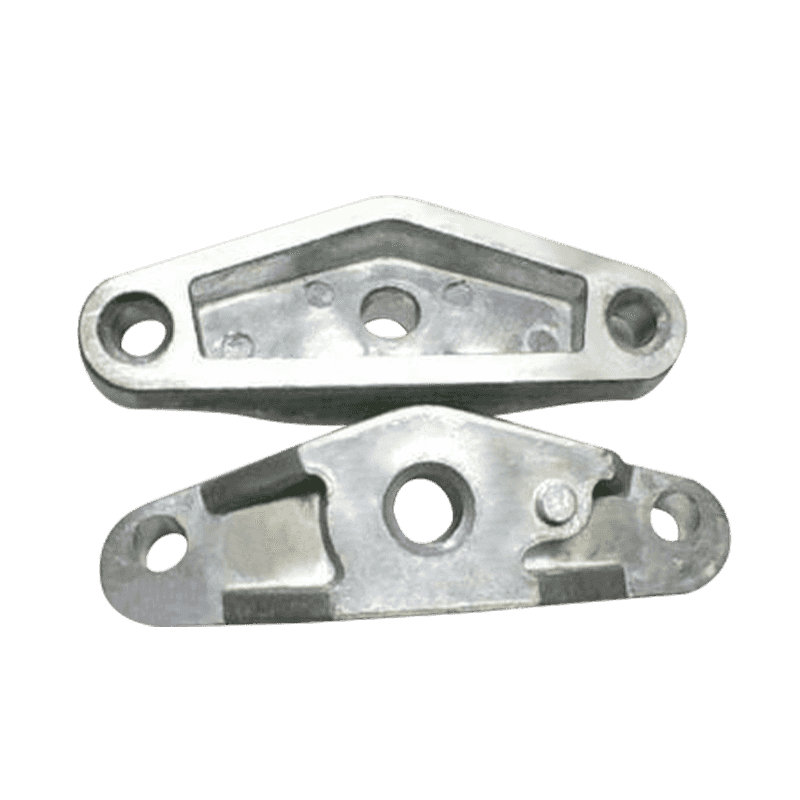

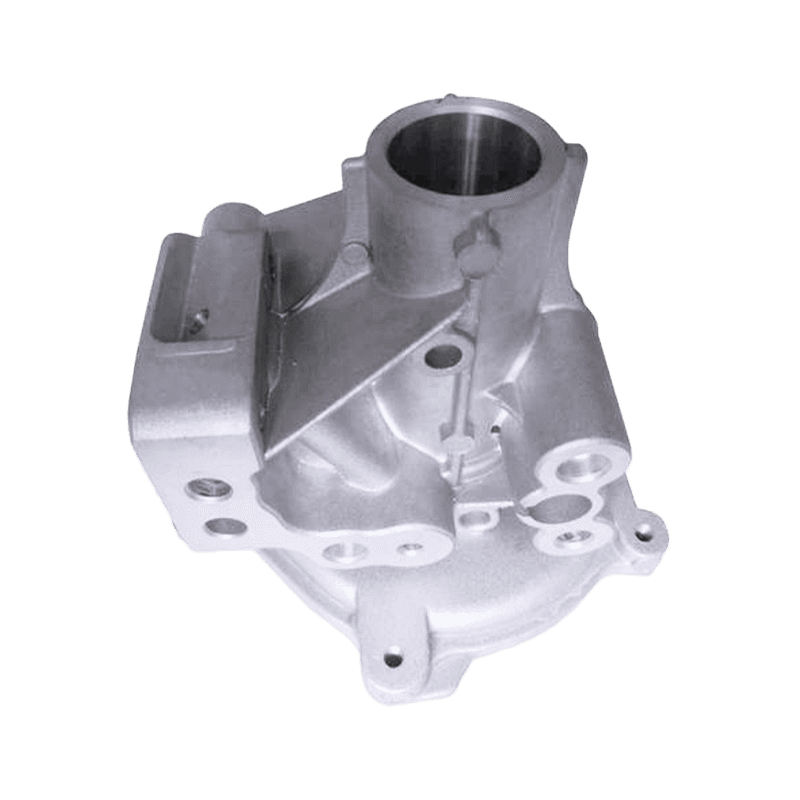

Aluminium alloy auto parts

Aluminium Alloy Auto Engine Parts Aluminium Alloy Automobile Transmission Parts

| 1. Drawings or Samples | We get the drawings or samples from customers. |

| 2. Drawings Confirmation | We will draw the 3D drawings according to the customers' 2D drawings or samples, and send the 3D drawings to customers for confirmation. |

| 3. Quotation | We will quote after getting the customers' confirmation, or quote directly according to customers' 3D drawings. |

| 4. Making Moulds/Patterns | We will make molds or pattens after getting the mold orders from the customers. |

| 5. Making Samples | We will make real samples using the molds and send them to customers for confirmation. |

| 6. Mass Producing | We will produce the products after getting the customers' confirmation and orders. |

| 7. Inspection | We will inspect the products by our inspectors or ask the customers to inspect together with us when finished. |

| 8. Shipment | We will ship the goods to the customers after getting the inspection result and the customers' confirmation. |

| Process: | 1) Die Casting / Profile Extrusion |

| 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading | |

| 3) Surface Treating | |

| 4) Inspection and Packaging | |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. |

| 2) Aluminum Alloys Profile Extrusion: 6061, 6063 | |

| 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. | |

| Surface Treatment: | Polishing |

| Shot Blasting | |

| Sandblasting | |

| Powder Coating | |

| Anodizing | |

| Chrome Plating | |

| Passivation | |

| E-coating | |

| T-coating | |

| etc. | |

| Tolerance: | +/-0.01mm |

| Weight Per Unit: | 0.01-5KG |

| Order Lead Time: | 20-45 Days (According to the Quantity and Complexity of the Product 1 |

-

-

Introduction to Zinc Die Casting Zinc die casting is a widely used manufacturing process for producing parts that require high precision, complex shap...

Read More -

Introduction to Aluminum Alloy Die-Casting in Automotive Applications Aluminum alloy die-casting has become a widely used manufacturing process in the...

Read More -

How does electric vehicle die casting affect the mechanical strength of electric vehicle components?

Background of Die Casting in Electric Vehicle Manufacturing Electric vehicle development has accelerated the adoption of advanced manufacturing proces...

Read More

Design Considerations for Die Casting Parts

Advantages of Die Casting Parts

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский