Does zinc die casting exhibit stable performance under high or low temperature environments?

12-02-2026General Characteristics of Zinc Die Casting Materials

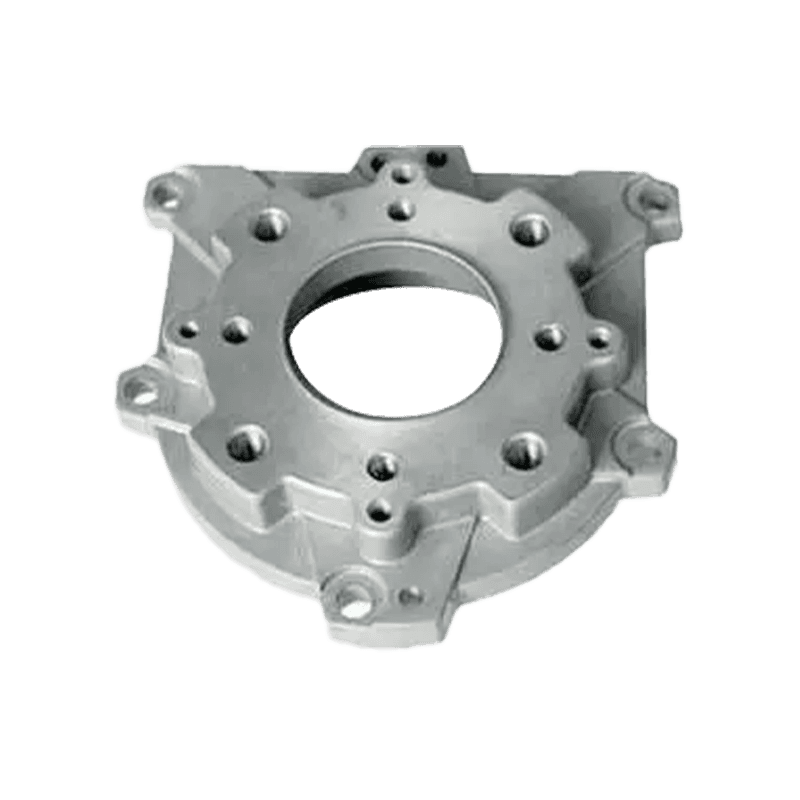

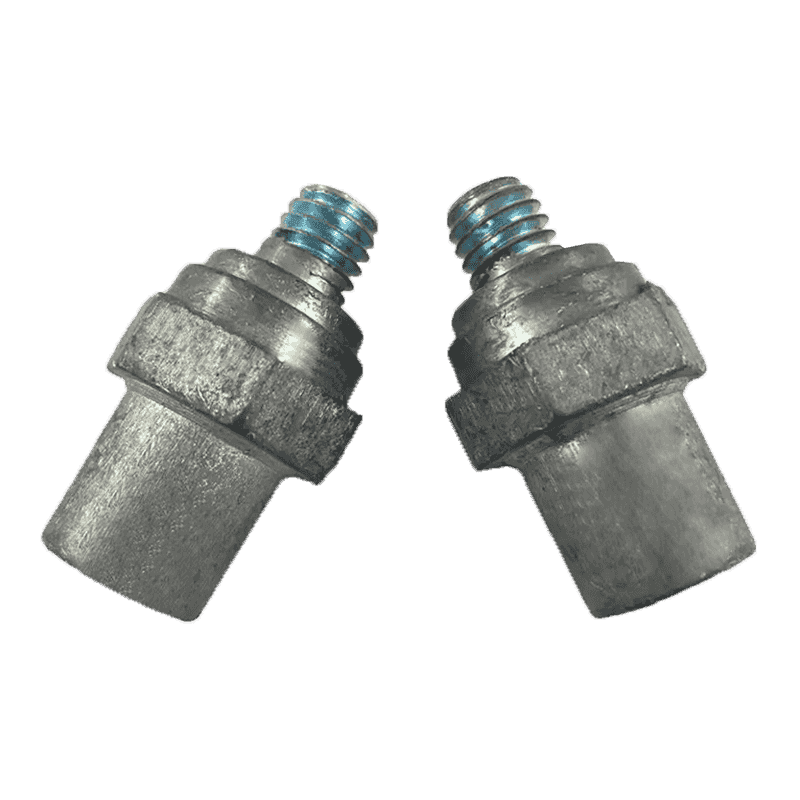

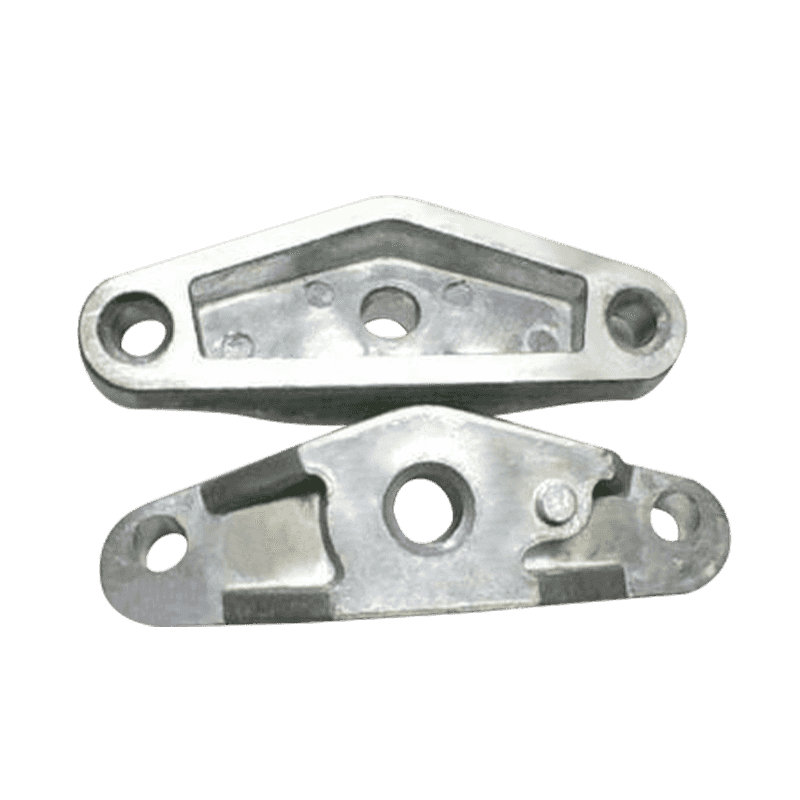

Zinc die casting is a manufacturing process that uses molten zinc alloy injected into precision molds to create components with consistent shapes and detailed features. Zinc alloys commonly used in die casting contain elements such as aluminum, magnesium, and copper, which influence mechanical strength, dimensional stability, and thermal behavior. These inherent material characteristics play a central role in determining how zinc die cast components perform when exposed to high or low temperature environments over extended periods.

Thermal Properties of Zinc Alloys

Zinc alloys exhibit a relatively low melting point compared to many other structural metals, typically around 380 to 420 degrees Celsius depending on composition. This lower melting point allows efficient casting but also defines the upper temperature limits for service applications. At moderate temperatures, zinc alloys maintain stable mechanical properties and dimensional accuracy. Their thermal conductivity is moderate, enabling heat to disperse evenly and reducing localized thermal stress during temperature changes.

Performance Behavior at Elevated Temperatures

Under high temperature conditions that remain well below the melting range, zinc die cast parts generally maintain predictable behavior. Mechanical strength gradually decreases as temperature rises, which is a natural response for metallic materials. However, within commonly specified operating ranges, zinc components can retain sufficient structural integrity for many applications such as automotive interior parts, electrical housings, and consumer products. Designers typically account for thermal softening by adjusting wall thickness and load distribution.

Dimensional Stability in Warm Environments

Dimensional stability is an important concern in temperature-sensitive applications. Zinc die cast components demonstrate relatively low thermal expansion compared to some aluminum alloys and plastics. This characteristic helps parts maintain consistent dimensions during moderate temperature fluctuations. In assemblies where tight tolerances are required, zinc components can offer predictable expansion behavior, reducing the likelihood of misalignment or interference when temperatures increase gradually.

Long-Term Exposure to Heat

When zinc die cast parts are exposed to elevated temperatures for long durations, creep behavior becomes a consideration. Creep refers to slow deformation under sustained load at higher temperatures. Zinc alloys may exhibit creep at temperatures above approximately 100 degrees Celsius, depending on stress levels and alloy composition. For this reason, zinc die casting is typically used in applications where prolonged high-temperature loading is limited or where stresses are carefully controlled.

Surface Integrity and Oxidation at High Temperatures

At elevated temperatures, zinc surfaces may undergo oxidation when exposed to air. This oxidation usually forms a thin, stable layer that can provide some surface protection. In most indoor or controlled environments, this process does not significantly compromise part performance. For higher temperature or outdoor applications, protective coatings or surface treatments are often applied to enhance corrosion resistance and maintain surface appearance.

Behavior in Low Temperature Environments

Zinc die casting is often considered suitable for low temperature conditions due to its ability to retain ductility better than some ferrous materials. As temperatures decrease, metals can become more brittle, increasing the risk of cracking under impact or sudden loading. Zinc alloys generally show stable mechanical response in cold environments commonly encountered in transportation, outdoor equipment, and infrastructure components.

Impact Resistance at Reduced Temperatures

At low temperatures, impact resistance is a key indicator of performance stability. Zinc alloys tend to maintain acceptable impact behavior down to sub-zero temperatures, especially when compared with certain plastics that may become brittle. This makes zinc die cast parts suitable for housings, brackets, and connectors used in cold climates, where resistance to sudden mechanical shock is necessary.

Thermal Cycling and Fatigue Considerations

Thermal cycling occurs when components repeatedly move between high and low temperatures. This process can introduce thermal fatigue due to expansion and contraction. Zinc die cast components generally handle thermal cycling well within defined temperature limits. The relatively uniform microstructure produced by die casting helps distribute thermal stresses evenly, reducing the likelihood of crack initiation under repeated cycles.

Influence of Alloy Composition on Temperature Performance

Different zinc alloys exhibit variations in thermal stability based on their specific compositions. Alloys with higher aluminum content may offer improved strength at moderately elevated temperatures, while those with controlled copper content can enhance wear resistance. Selecting the appropriate alloy is a critical step in ensuring stable performance across expected temperature ranges.

Comparison with Other Die Casting Materials

When compared with aluminum and magnesium die castings, zinc alloys offer a distinct balance of properties. Aluminum typically performs better at higher continuous service temperatures, while zinc provides advantages in dimensional accuracy and low-temperature behavior. Magnesium offers lightweight benefits but may require more careful temperature management. The choice among these materials often depends on the operating environment and functional requirements.

| Material | Typical Service Temperature Range | Low Temperature Behavior | High Temperature Considerations |

| Zinc Die Casting | -40°C to 100°C | Maintains ductility and impact resistance | Gradual strength reduction, possible creep |

| Aluminum Die Casting | -50°C to 150°C | Good performance with moderate brittleness risk | Better retention of strength |

| Magnesium Die Casting | -40°C to 120°C | Acceptable with design precautions | Requires careful thermal management |

Role of Design in Temperature Stability

Design decisions strongly influence how zinc die cast components perform under temperature extremes. Features such as uniform wall thickness, rounded corners, and proper rib placement help reduce thermal stress concentrations. Engineers often design zinc parts with allowances for thermal expansion and mechanical property changes to ensure stable function across temperature variations.

Manufacturing Quality and Its Thermal Impact

Consistent manufacturing quality contributes to stable temperature performance. Proper control of casting parameters, such as injection speed and cooling rate, ensures a uniform microstructure with minimal internal defects. Porosity or inclusions can become stress concentrators under thermal loading, so quality control measures are important for applications involving temperature fluctuations.

Surface Treatments and Coatings

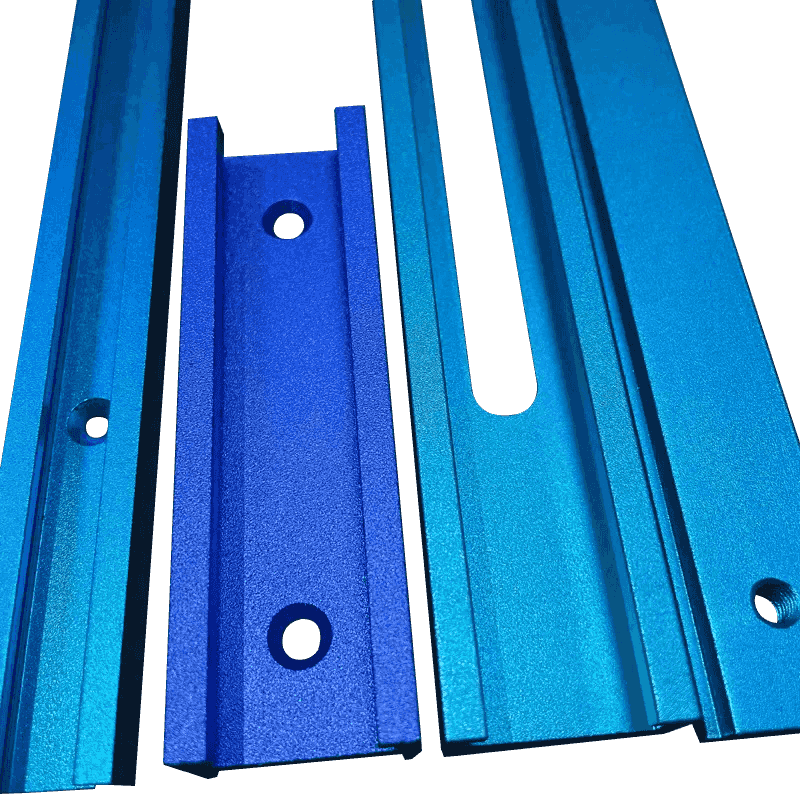

Surface treatments such as plating, powder coating, or passivation can enhance the thermal and environmental resistance of zinc die cast parts. These treatments may reduce oxidation, improve wear resistance, and provide additional protection in both hot and cold environments. While coatings do not change the base alloy’s melting point, they can help maintain surface integrity during temperature exposure.

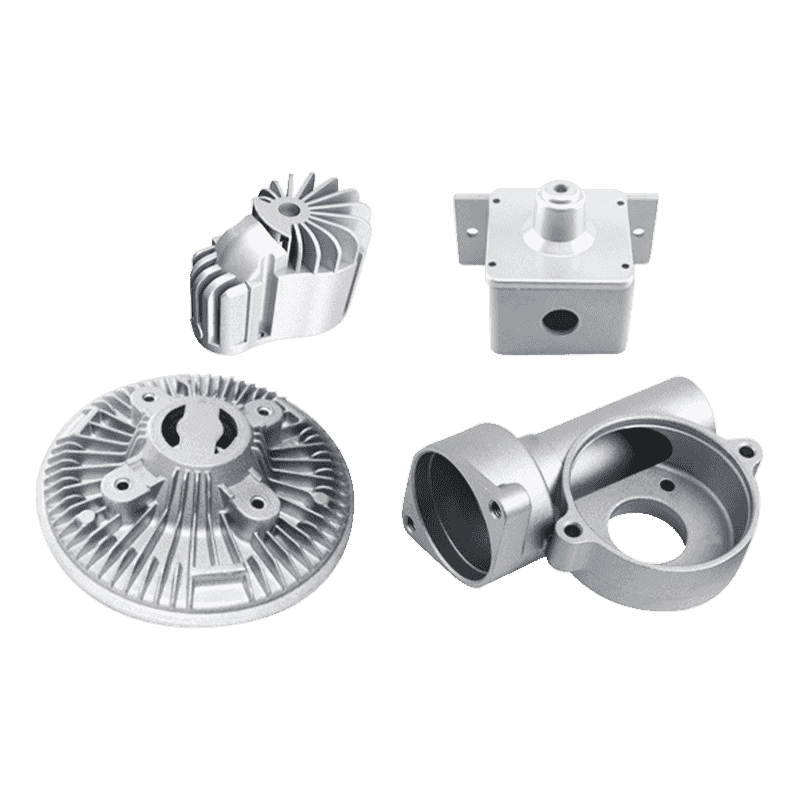

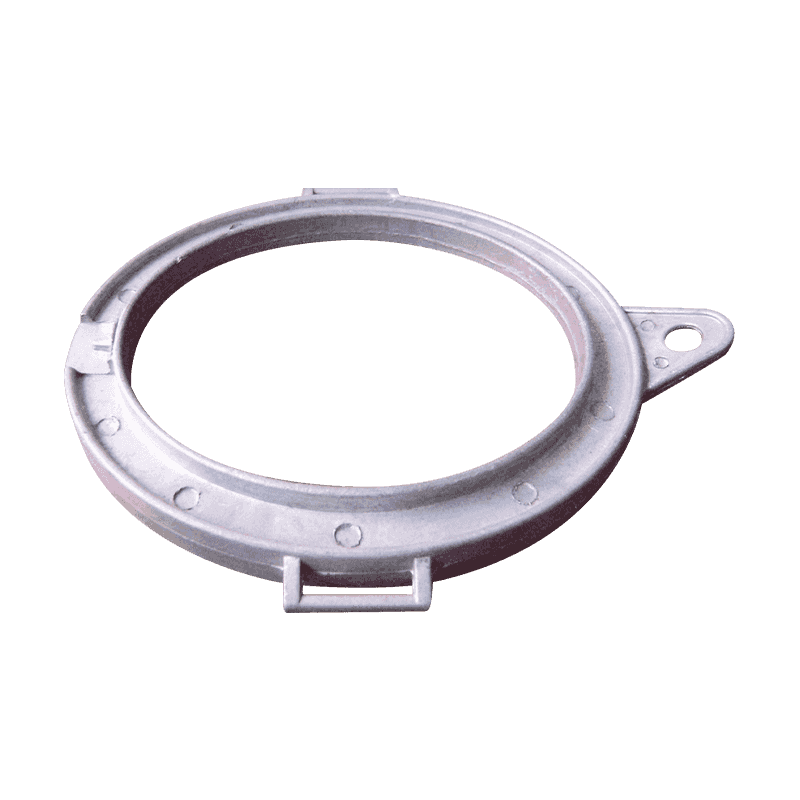

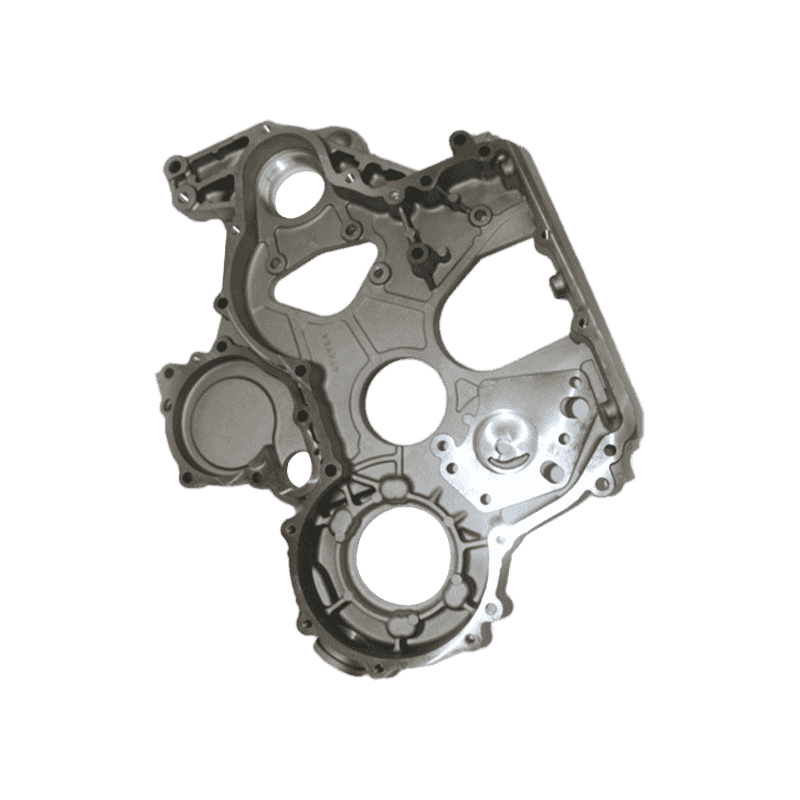

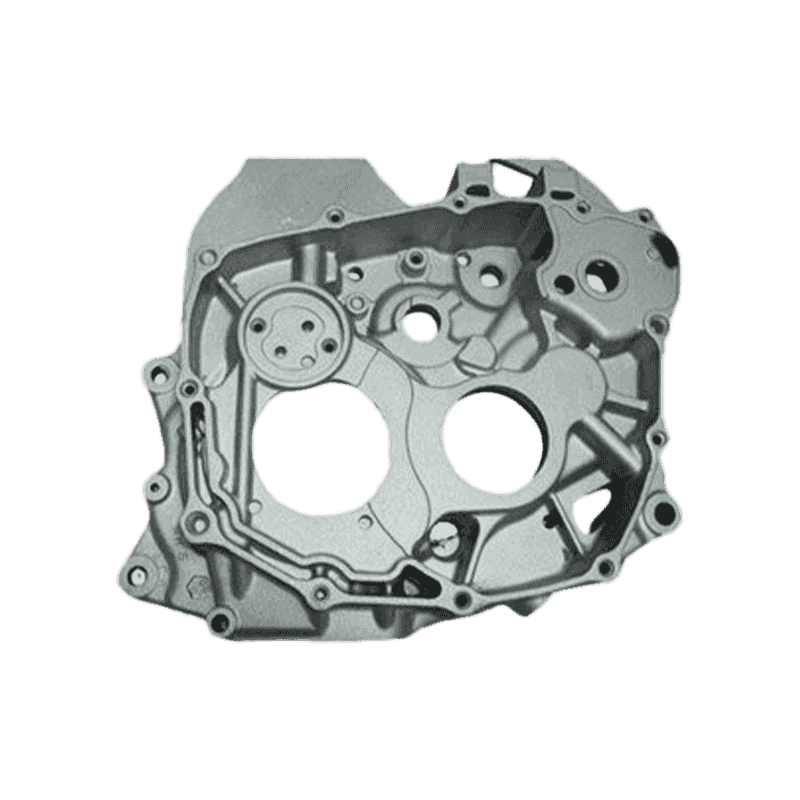

Applications Requiring Temperature Stability

Zinc die casting is commonly used in applications where temperature stability is necessary but extreme heat is not continuous. Examples include automotive interior components, electronic enclosures, appliance parts, and hardware fittings. In these uses, zinc offers a balance of mechanical reliability, dimensional consistency, and cost efficiency across a range of environmental conditions.

Environmental Factors Beyond Temperature

Temperature often interacts with other environmental factors such as humidity, vibration, and chemical exposure. Zinc die cast components generally handle combined environmental stresses well when properly designed and protected. Understanding how temperature interacts with these factors helps engineers select suitable materials and surface treatments.

Testing and Validation for Temperature Performance

Before deployment, zinc die cast components are often subjected to environmental testing that includes high-temperature exposure, low-temperature storage, and thermal cycling. These tests help verify that parts maintain functionality, dimensional accuracy, and mechanical strength under anticipated conditions. Test results guide design refinements and material selection for reliable long-term use.

Practical Expectations for Temperature Stability

In practical terms, zinc die casting exhibits stable and predictable performance within commonly specified temperature ranges. While it is not intended for continuous exposure to very high temperatures, it performs reliably in both warm and cold environments encountered in many industrial and consumer applications. Understanding material limits and applying appropriate design practices allows zinc die cast components to function consistently under varying thermal conditions.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский