Can the mechanical strength of zinc die casting meet the requirements for structural parts?

09-10-2025Mechanical Strength of Zinc Die Casting in Structural Applications

Zinc die casting is widely used in various industries because of its balance between mechanical strength, casting precision, and cost-effectiveness. When considering whether zinc die casting can meet the requirements for structural parts, several factors come into play, including tensile strength, impact resistance, elongation, and load-bearing capacity. The material’s microstructure, alloy composition, and casting process quality all influence its final performance. Understanding these characteristics allows engineers to evaluate its suitability for structural applications where stability, durability, and resistance to stress are essential.

Fundamental Properties of Zinc Die Casting

The base properties of zinc die casting make it an attractive option for certain structural parts. Zinc alloys typically offer tensile strengths ranging between 280 MPa and 400 MPa, depending on the alloy type. They also exhibit good hardness and dimensional stability, which is particularly important for maintaining consistent structural integrity under mechanical loads. These properties make zinc suitable for medium-load structural applications, particularly in sectors such as automotive, electronics housing, and consumer goods where precision and stability are required.

Comparison with Alternative Structural Materials

When evaluating zinc die casting for structural parts, it is necessary to compare it with other metals such as aluminum, steel, or magnesium. Steel has higher tensile strength and is often used for heavy structural loads, while aluminum provides a lighter weight alternative with a good strength-to-weight ratio. Zinc die casting offers a middle ground, providing adequate strength with excellent castability and lower production costs. For non-critical or medium-load structural applications, zinc alloys may provide sufficient strength while also reducing manufacturing complexity.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Typical Application |

|---|---|---|---|

| Zinc Alloy | 280–400 | 6.6–6.8 | Medium structural parts, housings, brackets |

| Aluminum Alloy | 200–500 | 2.7 | Lightweight structures, automotive frames |

| Steel | 400–1000+ | 7.8 | Heavy-duty load-bearing components |

Load-Bearing Capacity and Structural Stability

One of the core requirements for structural parts is the ability to sustain mechanical loads without excessive deformation. Zinc die casting can withstand considerable loads, particularly in components such as brackets, housings, or enclosures where static or moderate dynamic stresses are applied. However, in applications requiring very high load-bearing performance, steel or reinforced aluminum may be more suitable. Zinc’s strength and hardness allow it to maintain dimensional stability, which is critical for parts that must interlock or fit precisely within assemblies.

Resistance to Impact and Fatigue

Structural parts are often exposed to repeated stress cycles or occasional impacts, making fatigue resistance an important consideration. Zinc die casting provides reasonable impact resistance, although it is lower than that of steel. Fatigue resistance is adequate for medium-duty applications but may not be sufficient in scenarios involving continuous heavy vibration or fluctuating loads. Engineers must assess the expected operational environment to determine whether zinc’s fatigue performance aligns with the requirements of the part.

Thermal Stability and Deformation Resistance

Structural parts frequently encounter temperature changes, which can influence mechanical performance. Zinc die casting maintains dimensional stability in normal operating temperature ranges, typically between -40°C and 120°C. Beyond this range, zinc alloys may experience creep or reduced strength, which could impact structural integrity. For high-temperature structural environments, alternative alloys with higher thermal resistance may be necessary. Nonetheless, within common temperature ranges, zinc provides stable performance for structural parts.

Corrosion Resistance and Long-Term Durability

Another factor in evaluating zinc die casting for structural parts is corrosion resistance. Zinc alloys naturally form a protective oxide layer that resists atmospheric corrosion, making them suitable for indoor and moderately corrosive outdoor environments. Additional surface treatments, such as electroplating, powder coating, or painting, can further enhance durability. For structural parts expected to function in harsh or corrosive environments, such protective coatings are essential to maintain long-term mechanical integrity.

| Factor | Performance in Zinc Die Casting | Design Consideration |

|---|---|---|

| Tensile Strength | 280–400 MPa | Suitable for medium loads |

| Impact Resistance | Moderate | Adequate for brackets and housings |

| Thermal Stability | -40°C to 120°C | Stable in typical environments |

| Corrosion Resistance | Good with protective coating | Enhancements required outdoors |

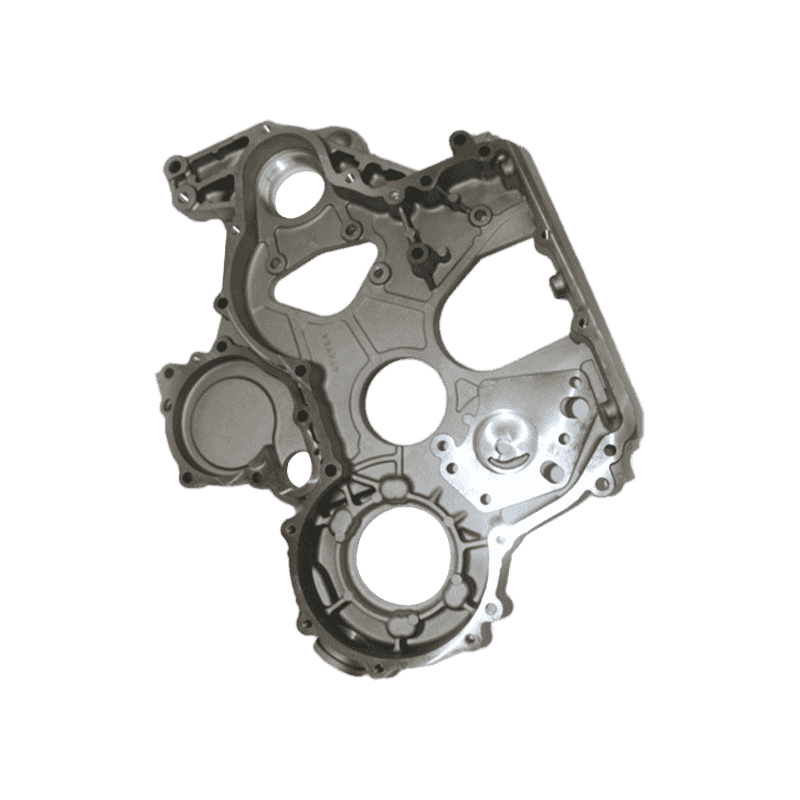

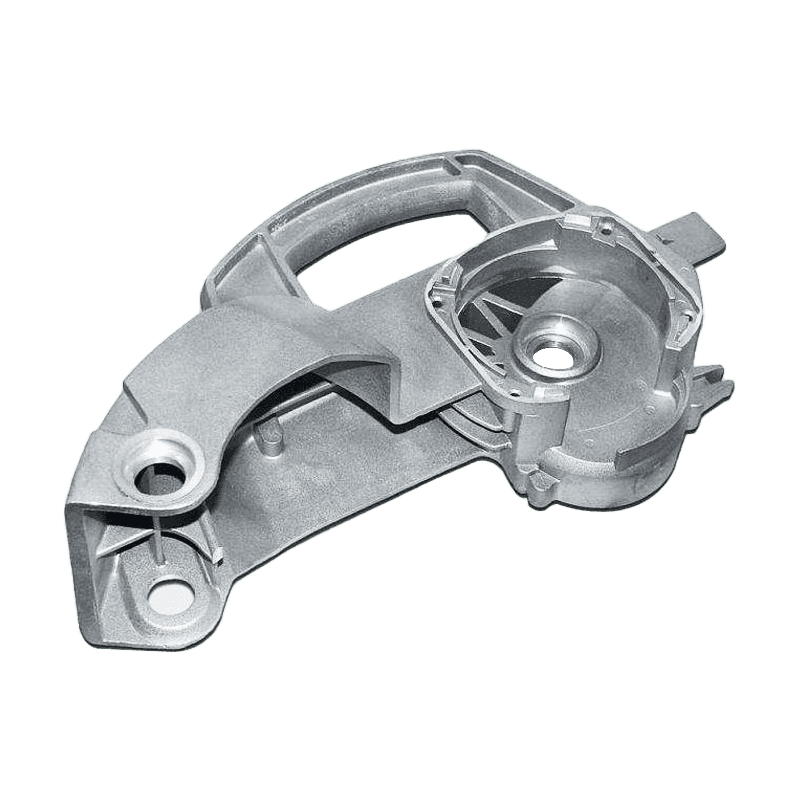

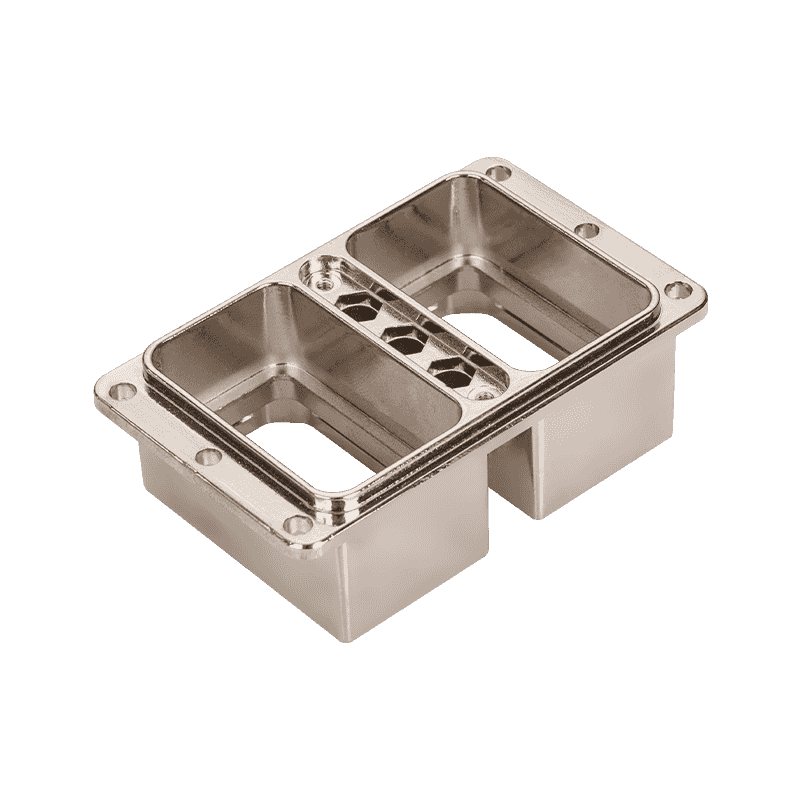

Design Optimization for Structural Applications

When using zinc die casting for structural components, proper design considerations help maximize mechanical performance. Engineers often employ ribbing, fillets, and optimized geometries to improve load distribution and minimize stress concentrations. Thicker cross-sections may be necessary to increase strength in certain applications. Through careful design, zinc die cast structural parts can achieve reliable performance, even when subjected to moderate loads and environmental variations.

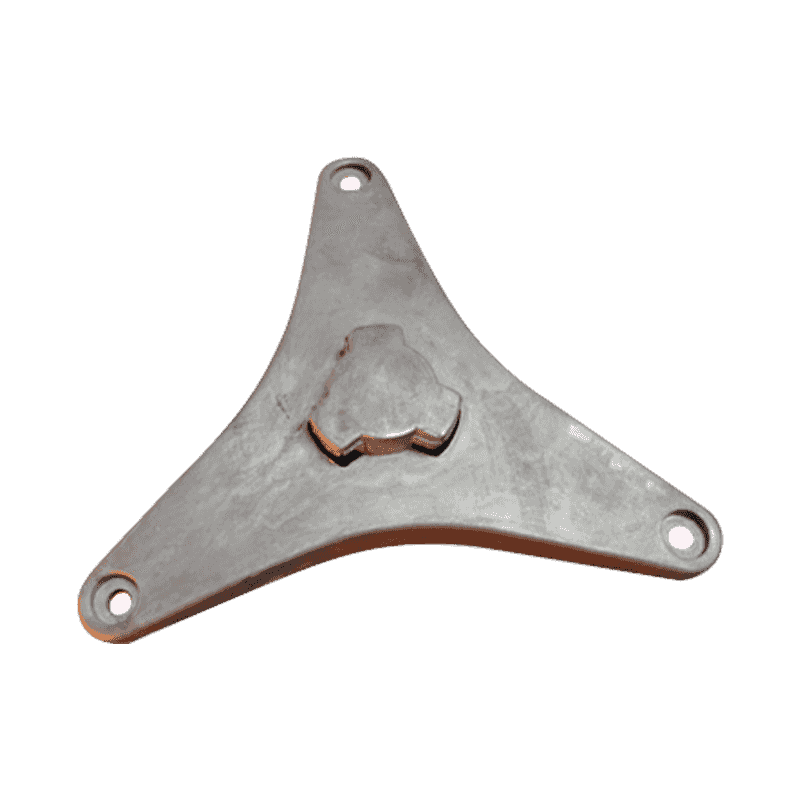

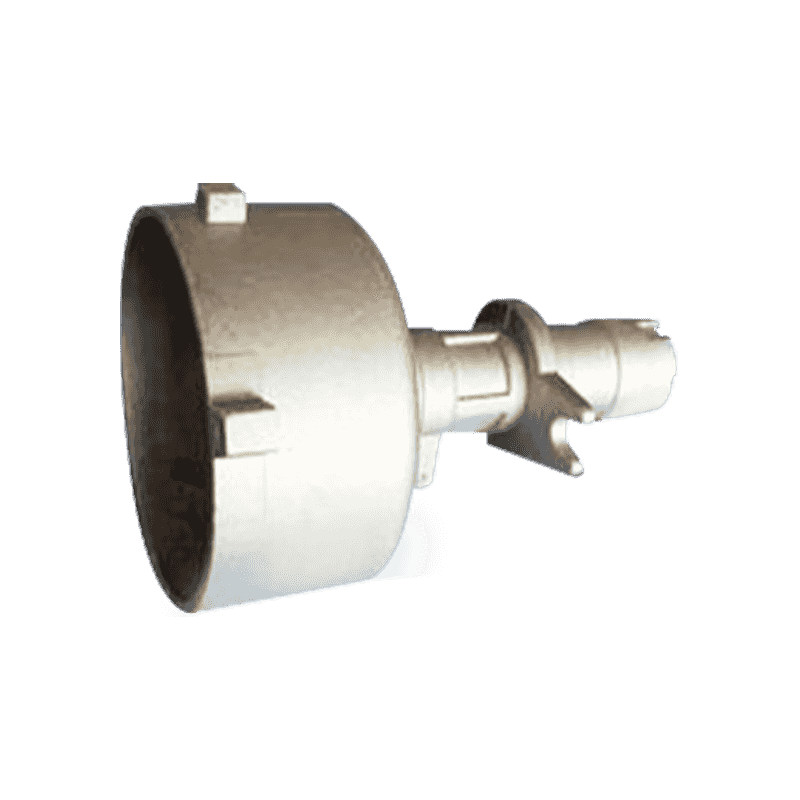

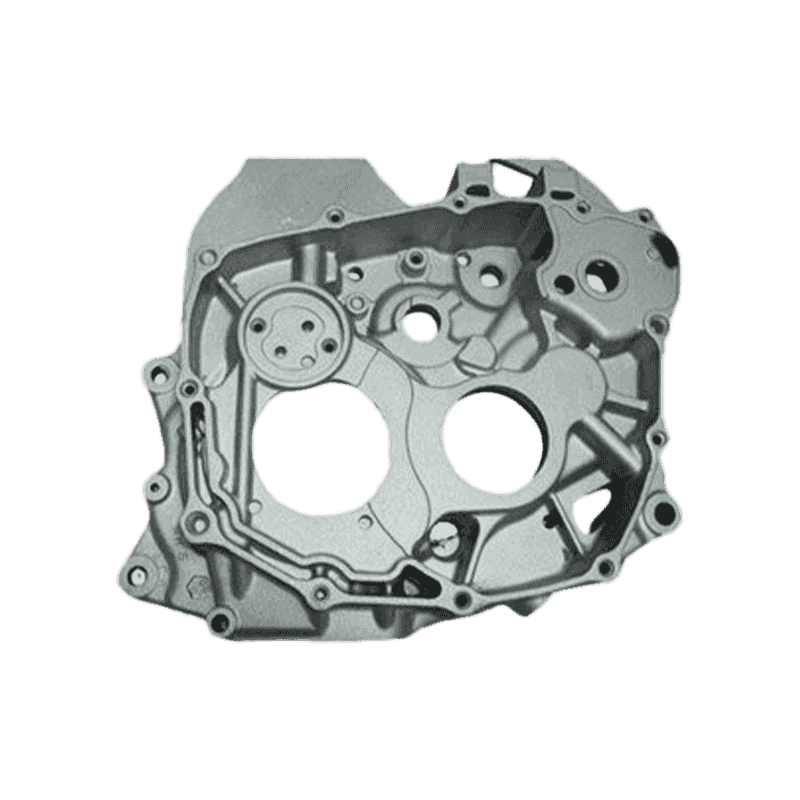

Case Studies of Zinc Die Casting in Structural Roles

Practical applications highlight how zinc die casting meets structural requirements. In the automotive industry, zinc is used in door lock housings, brackets, and small chassis components, where moderate load-bearing is required. In consumer products, structural housings for electronics and household devices rely on zinc alloys for their combination of strength and precision. These case studies illustrate that while zinc may not replace steel in heavy-duty load-bearing roles, it performs effectively in medium-load structural applications.

Economic and Production Considerations

Beyond mechanical strength, zinc die casting offers significant manufacturing benefits that enhance its suitability for structural applications. Its low melting point allows for longer die life, reduced energy consumption, and higher casting precision. This means complex structural parts can be produced with tight tolerances and minimal machining. The cost advantage combined with sufficient strength makes zinc an appealing choice for many medium-duty structural applications where mass production efficiency is essential.

Future Developments in Zinc Die Casting Alloys

Ongoing research into zinc alloy formulations aims to enhance mechanical performance, particularly in terms of tensile strength and thermal resistance. New alloying techniques and casting technologies are extending the potential of zinc die casting in structural applications. Improved microstructural control and the addition of elements like aluminum or magnesium are being explored to boost strength while maintaining castability. These advancements may further expand zinc’s role in structural applications in industries such as automotive, aerospace, and industrial machinery.

Maintenance and Lifecycle Considerations

The performance of structural parts also depends on their lifecycle behavior. Zinc die casting parts generally require low maintenance when properly designed and coated for corrosion protection. Their dimensional stability and resistance to wear extend their service life, reducing the need for frequent replacements. Lifecycle cost analysis often shows that zinc die casting provides a balance between performance, durability, and economic feasibility for structural components.

Conclusion of Structural Suitability

Zinc die casting possesses mechanical properties that make it capable of meeting the requirements for structural parts in many applications, particularly those involving moderate loads and environments with controlled temperatures. While it cannot fully replace high-strength steel in heavy-duty roles, its balance of strength, castability, corrosion resistance, and cost-efficiency make it a valuable option for structural designs. With proper engineering considerations, surface treatments, and optimized geometries, zinc die cast parts can maintain mechanical strength and provide reliable performance as structural components.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский