Which surface treatment methods can improve the wear resistance of zinc alloy die-cast auto parts?

05-11-2025Overview of Wear Resistance Requirements in Zinc Alloy Die-Cast Auto Parts

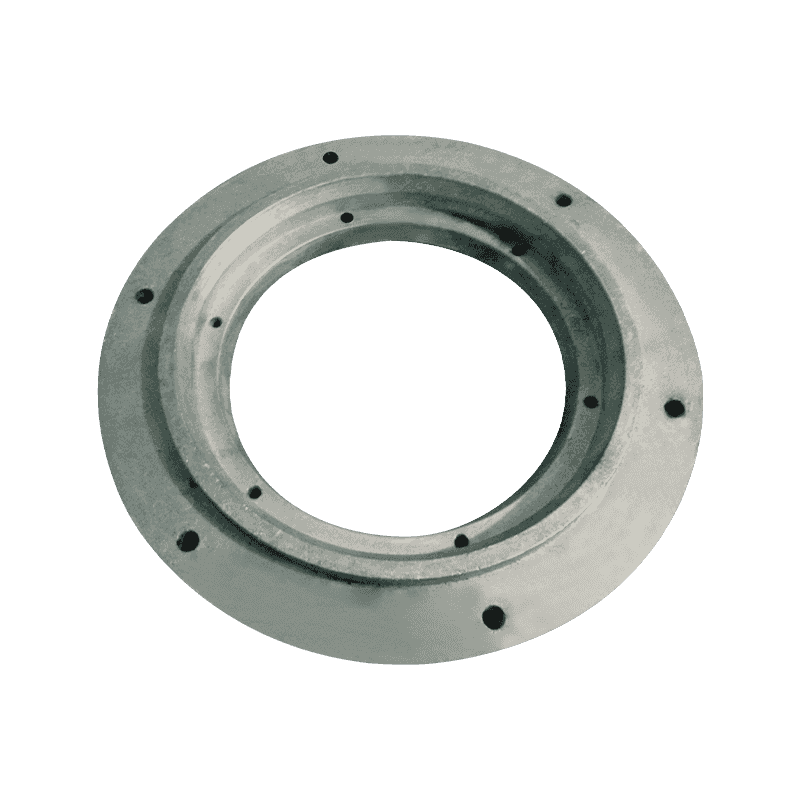

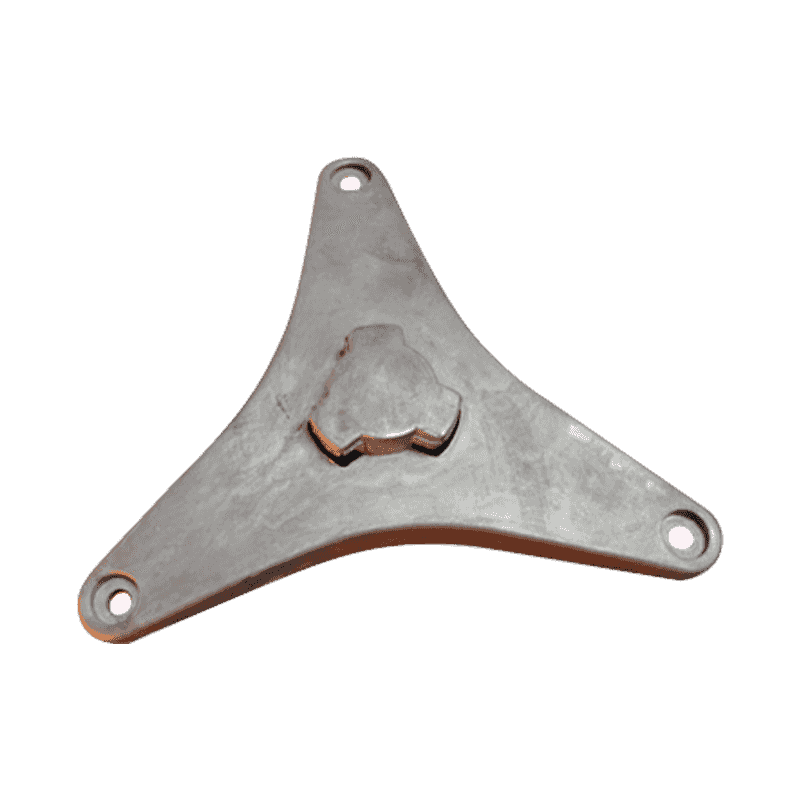

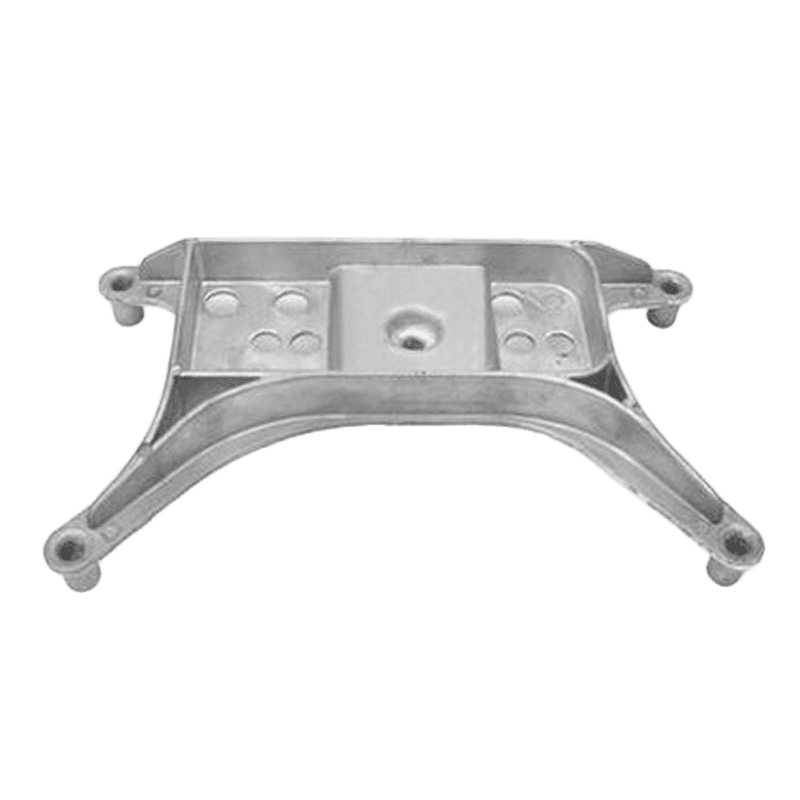

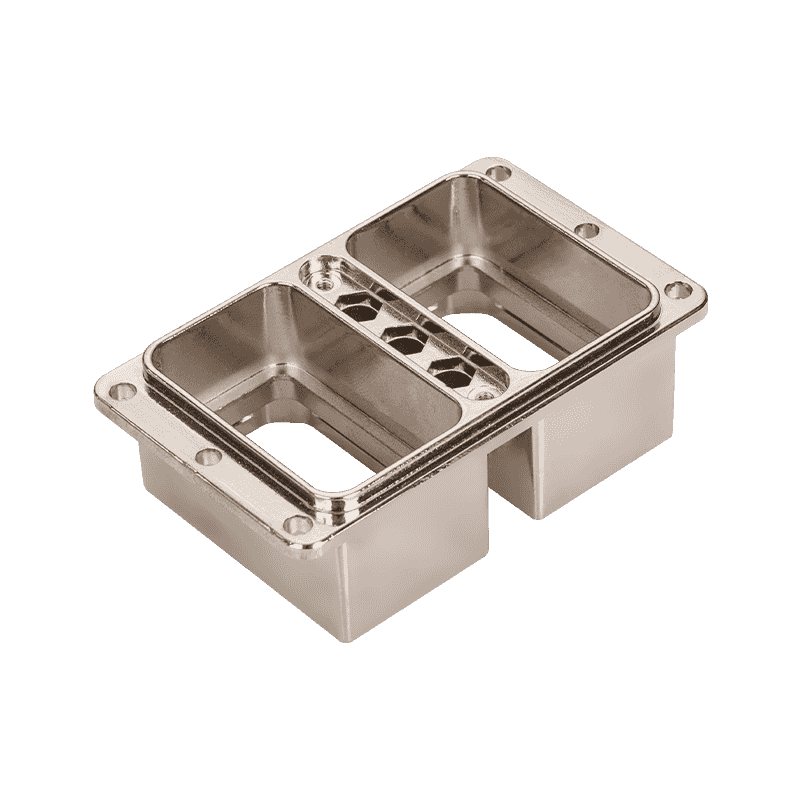

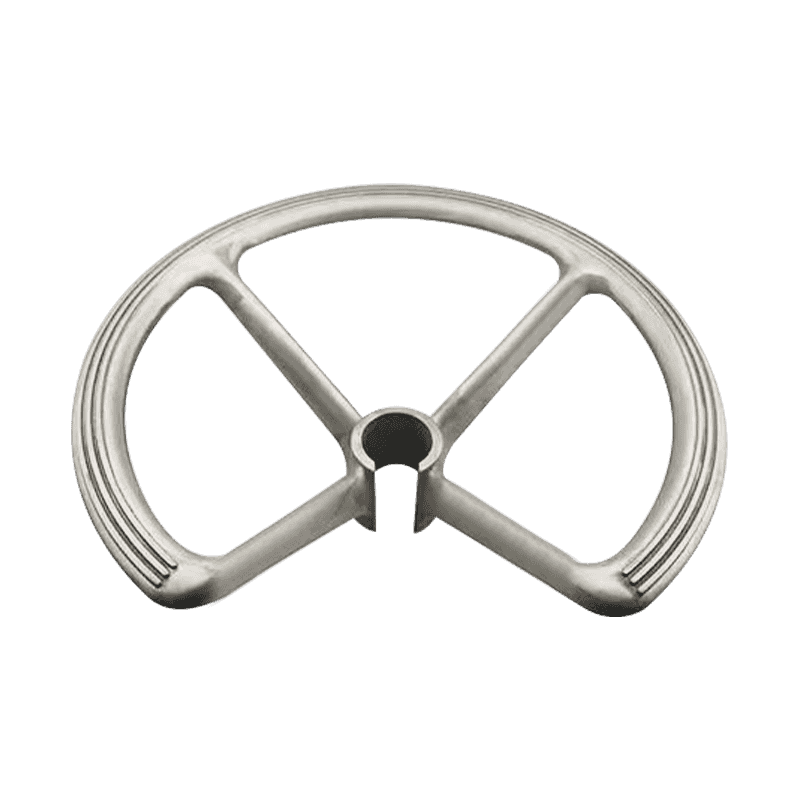

Zinc alloy die-cast auto parts are widely applied in vehicle structures, interior mechanisms, and functional assemblies that require detailed shapes and stable dimensional accuracy. Although zinc alloys offer good castability and moderate strength, their wear resistance is often lower compared with steel or certain aluminum alloys. As a result, automotive manufacturers frequently adopt surface treatment methods to improve durability, reduce friction, and extend service life under repeated mechanical contact. These surface technologies address challenges such as abrasion, sliding wear, corrosion-induced wear, and surface fatigue caused by dynamic loads. By applying suitable treatments to zinc alloy die-cast components, companies can enhance performance while maintaining lightweight structures and cost-effective production. Surface engineering therefore becomes a key factor in ensuring that zinc alloy components remain reliable when used in moving mechanisms, fasteners, decorative trims, and supporting housings in the automotive industry.

Electroplating as a Wear Resistance Enhancement Method

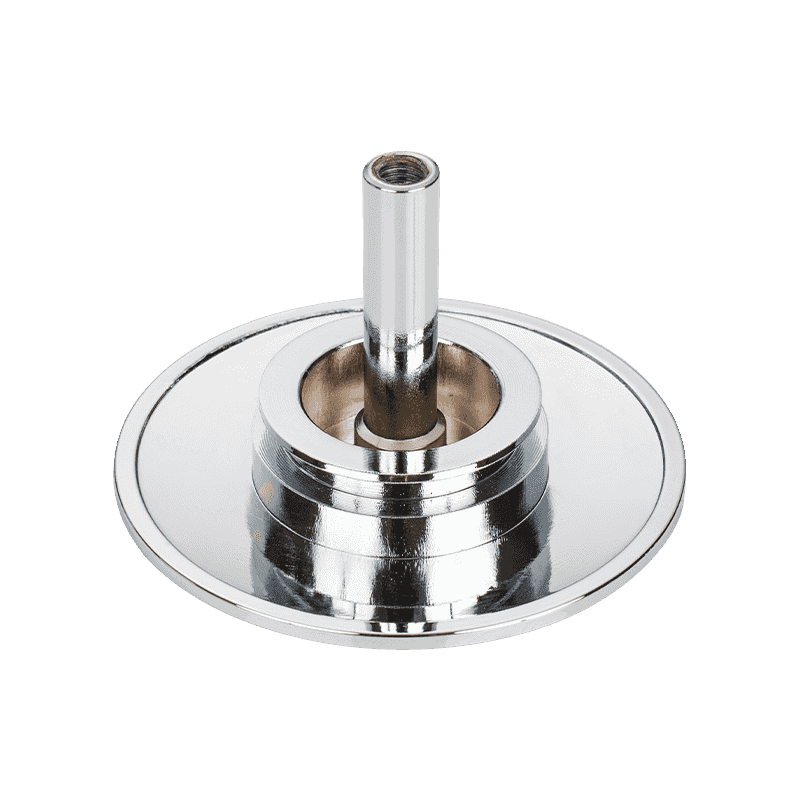

Electroplating is one of the most widely adopted techniques for improving the surface properties of zinc alloy die-cast auto parts. It involves depositing a thin, functional metal layer on the part’s surface through an electrochemical process. Plating materials such as nickel, chromium, copper-nickel combinations, or alloyed coatings can strengthen the surface, making it more resistant to friction and repeated contact. Nickel plating is typically preferred for its ability to create a dense and stable barrier layer that withstands sliding wear. Chromium plating can offer additional hardness as well as aesthetic benefits, which is valuable for visible automotive parts such as handles and decorative trims. Electroplated coatings also contribute to corrosion resistance, reducing the likelihood that environmental degradation will weaken the surface over time. The uniform coating formation is especially important for die-cast parts with complex geometries because consistent thickness ensures stable performance in varied contact areas.

| Coating Type | Main Purpose | Typical Application on Auto Parts |

|---|---|---|

| Nickel Plating | Improves surface hardness and friction resistance | Interior mechanisms, rotating components |

| Chromium Plating | Enhances wear resistance and corrosion stability | Exterior trims, handle components |

| Copper-Nickel Layers | Provides base adhesion and additional protection | Decorative and structural parts requiring layered coatings |

Electroless Plating for Uniform and Stable Surface Hardening

Electroless plating differs from traditional electroplating by eliminating the need for external electrical current. Instead, the chemical bath itself drives the deposition reaction, producing consistent layers even on intricate geometries. This characteristic makes electroless nickel plating a valuable method for die-cast zinc components that contain cavities, recesses, or hard-to-reach surfaces. The resulting coating typically exhibits uniform thickness, high stability, and predictable hardness. Phosphorus or boron may be included in the coating to further improve wear behavior, giving the surface additional resistance to sliding, fretting, and high-contact applications. Automotive parts subjected to frequent movement or micro-vibration particularly benefit from this technique. Electroless coatings also offer stable corrosion protection, which helps maintain the surface integrity necessary for long-term wear resistance.

Powder Coating as a Protective Wear Layer

Powder coating is often selected for zinc alloy auto parts when a thicker and more impact-resistant protective layer is desired. Applied electrostatically and cured under heat, the coating forms a continuous polymeric layer that provides resistance to light mechanical wear and environmental exposure. Although powder coating is not a high-hardness solution like nickel or chromium plating, its durability and coating thickness make it useful for components that require protection from abrasion, mild friction, or repeated handling. Powder-coated zinc alloy components commonly appear in areas where both appearance and durability matter, particularly in interior structural parts or covers that experience moderate surface contact. The method also offers the advantage of uniform coverage without solvent use, reducing environmental impact while producing a smooth, consistent finish.

Anodizing-Like Treatments Modified for Zinc Alloys

Traditional anodizing is typically applied to aluminum, but modified processes exist for zinc alloy surfaces. These processes create conversion layers that increase the surface hardness and improve wear resistance. Although zinc alloy anodizing does not produce the same hardness level as aluminum oxide layers, the treatment still enhances surface structure, adhesion, and friction stability. The resulting protective film can be combined with sealing treatments or post-coating applications to further improve performance. These anodizing-like conversion coatings are often used for components requiring both functional enhancement and improved paint or coating adhesion. Automotive parts benefiting from these treatments include interior components, brackets, and accessory housings where moderate wear may occur.

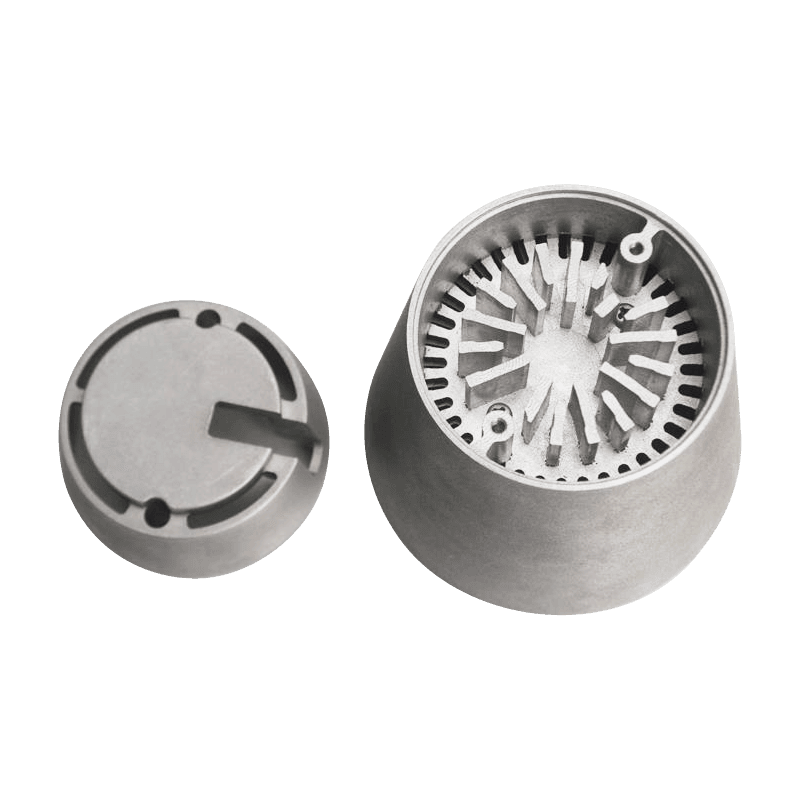

PVD Coating for Hard and Dense Finishes

Physical Vapor Deposition (PVD) offers a high-performance solution for enhancing the wear resistance of zinc alloy die-cast auto parts. This vacuum-based process forms hard, thin films that significantly reinforce the surface against abrasion and repeated sliding contact. Coatings such as titanium nitride (TiN), chromium nitride (CrN), or diamond-like carbon (DLC) are commonly selected for their hardness, friction-reducing properties, and consistent finish. Although PVD is typically more expensive than plating, it is favored for components that require robust wear performance in compact or high-precision applications. In the automotive industry, PVD coatings are used on switch components, gear-related mechanisms, moving interfaces, and decorative trims requiring enhanced surface protection without adding substantial thickness.

| PVD Coating Type | Main Advantages | Suitable Auto Part Scenarios |

|---|---|---|

| TiN | High hardness and stable wear resistance | Metal contacts, sliding interfaces |

| CrN | Corrosion protection combined with durability | Functional assemblies exposed to humidity |

| DLC | Low friction coefficient and strong wear tolerance | Precision parts and small mechanical components |

Heat Treatment and Alloy Reinforcement

Although zinc alloys have a relatively low melting point compared with many other metals, certain heat treatment processes can modify their microstructure to support better wear performance. These techniques aim to refine grain boundaries, enhance bonding between alloy constituents, and improve overall stability under mechanical stress. Heat treatment may also prepare the surface for additional coating processes by increasing adhesion or improving uniformity. When combined with plating, PVD, or chemical conversion layers, heat-treated zinc components achieve a more durable configuration suitable for automotive wear requirements. This approach is particularly effective for brackets, joints, and mechanical connectors that undergo continuous stress during operation.

Shot Peening and Surface Texturing

Mechanical treatments such as shot peening can increase the wear resistance of zinc alloy die-cast components by introducing compressive stresses on the surface. This process enhances fatigue life and limits crack initiation under repeated friction or impact. Surface texturing techniques, including laser texturing, can also improve lubricant retention in areas that require consistent friction control. In automotive applications where zinc alloy parts interact with other metal or polymer components, improved surface patterns help maintain stable friction while reducing excessive wear. These mechanical methods are often used in combination with additional coatings to maximize performance and stability.

Chemical Conversion Coatings for Foundation Protection

Chemical conversion coatings, such as chromate or phosphate treatments, provide a protective base layer for zinc alloy die-cast auto parts. While these coatings alone may not contribute high levels of wear resistance, they create a chemically stable surface that improves adhesion for subsequent plating or organic coatings. By preventing early corrosion or surface degradation, the conversion layer helps maintain surface integrity during long-term use. For automotive components exposed to moisture or varying temperatures, this foundational layer plays an important supporting role in ensuring stable wear performance throughout the part’s lifespan.

Combining Multiple Surface Treatments for Enhanced Performance

In many automotive applications, the best approach to improving wear resistance involves combining multiple surface treatment methods. For example, a zinc alloy die-cast part may first receive a conversion coating to prepare the surface, followed by electroless nickel plating for hardness, and finally a PVD layer for friction reduction. Such hybrid systems allow manufacturers to customize surface performance based on specific mechanical requirements, contact environments, and aesthetic considerations. Multi-layer configurations also help extend the lifespan of components used in demanding environments, such as moving mechanisms, hinged parts, or systems exposed to regular vibration. By carefully selecting complementary treatments, automotive engineers can achieve a balance between structural integrity, environmental stability, and long-term wear behavior.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский