Can aluminium profile electronic fittings be customized to specific designs or sizes?

18-12-2025Introduction to Aluminium Profile Electronic Fittings

Aluminium profile electronic fittings are versatile components widely used in various industries, including electronics, construction, automotive, and more. These fittings are primarily made from aluminium profiles, which are extruded shapes of aluminium designed to serve specific functional purposes in mechanical and electrical applications. The key benefits of aluminium profiles include their lightweight nature, strength, corrosion resistance, and ease of customization.

The Need for Customization in Aluminium Profile Electronic Fittings

Customization of aluminium profile electronic fittings is often necessary to meet specific design requirements or size constraints in projects. Standard, off-the-shelf fittings may not always provide the necessary functionality or compatibility with the electronic equipment they are intended to house or support. Therefore, manufacturers of aluminium profiles offer customization options, allowing engineers and designers to create fittings that precisely match their specifications. This customization can include adjusting the dimensions, shapes, finishes, or adding special features to the profile to improve performance or aesthetics.

Customization Options for Aluminium Profile Electronic Fittings

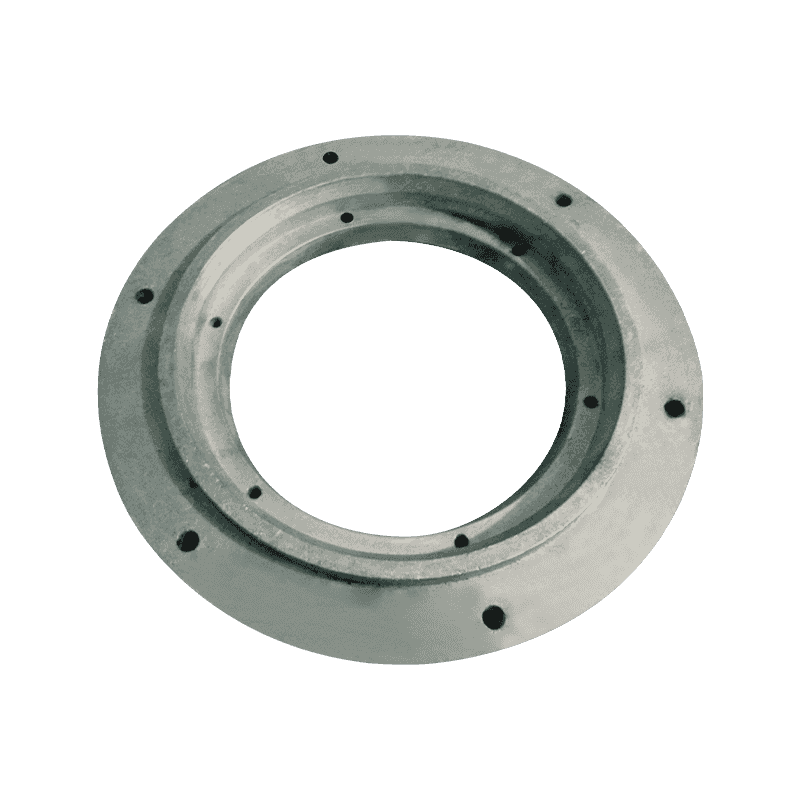

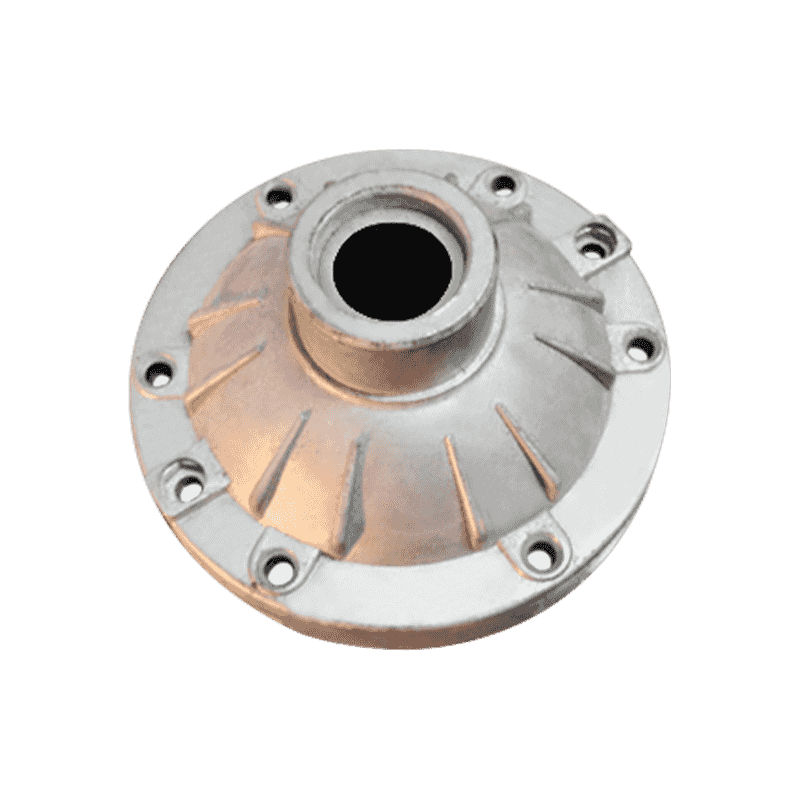

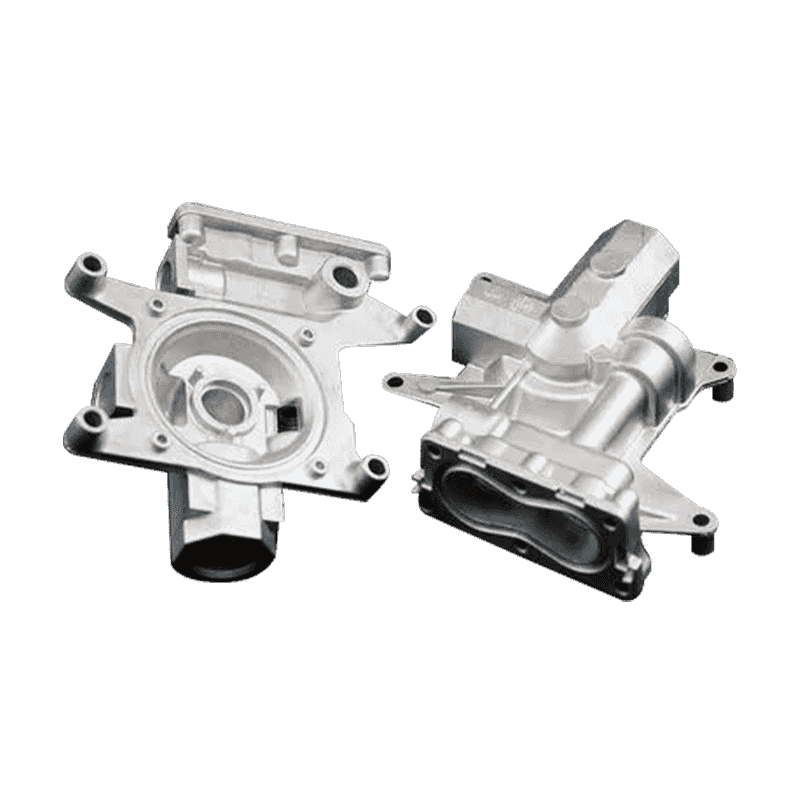

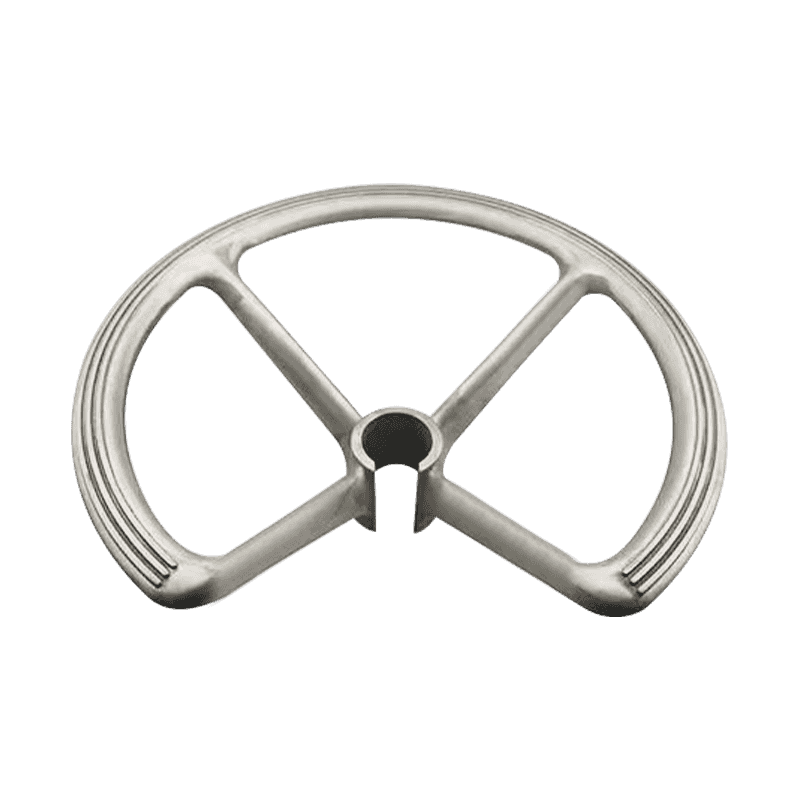

Aluminium profiles can be customized in several ways depending on the needs of the project. These options include modifications to the profile's size, shape, and functionality. One of the most common customization options is the adjustment of the profile’s dimensions. Whether a fitting needs to be longer, shorter, wider, or thinner, the flexibility of aluminium extrusion allows manufacturers to create profiles in virtually any size. Custom shapes, such as angular or circular profiles, can also be produced to suit specific applications.

Another area of customization is the addition of features such as slots, holes, or mounting points. These additions can be tailored to accommodate specific electrical components or connectors, enhancing the functionality of the fitting. Surface finishes are also a critical aspect of customization. Depending on the environment in which the fitting will be used, a specific finish can be applied to improve durability, aesthetics, or resistance to environmental factors. Popular finishes include anodizing, powder coating, and brushed aluminium, each providing unique characteristics for different applications.

Benefits of Customizing Aluminium Profile Electronic Fittings

Customizing aluminium profile electronic fittings provides several advantages that can significantly enhance the efficiency and performance of electronic equipment. One of the key benefits is that custom profiles can be designed to fit perfectly within the specific space available in the final product, ensuring a precise fit. This is particularly important when dealing with complex or compact electronic systems where space is limited.

Customisation also allows manufacturers to create profiles that are better suited to specific technical requirements. For example, a custom profile might feature better heat dissipation properties, allowing it to handle more power or maintain a lower temperature, which is crucial in high-performance electronics. Additionally, customizing the fittings enables the inclusion of specific features that enhance functionality, such as cable management slots, mounting holes, or integrated cooling solutions. By designing the profile to meet these exact requirements, manufacturers can improve the overall reliability and longevity of the electronic components they house.

The Process of Customizing Aluminium Profile Electronic Fittings

The process of customizing aluminium profile electronic fittings generally begins with a detailed consultation between the client and the manufacturer. During this phase, the specific requirements of the project are discussed, including the intended use of the fittings, size limitations, load-bearing capacity, and any special features or finishes required. This step is critical as it ensures that the manufacturer fully understands the project's needs before moving to the next stage.

Once the specifications are finalized, the manufacturer will begin the design process, which may involve creating prototypes or samples. These prototypes are tested for compatibility with other components and for performance under real-world conditions. Once the prototypes are approved, the manufacturer will proceed with mass production, during which the aluminium profiles are extruded and any necessary modifications, such as drilling or finishing, are carried out.

Applications of Customised Aluminium Profile Electronic Fittings

Customized aluminium profile electronic fittings have a broad range of applications in various industries. In the electronics industry, they are commonly used as housings for circuit boards, power supplies, and other components. Custom profiles allow for more efficient integration of electrical parts, leading to cleaner designs and improved performance. These profiles are also used in the construction of display units, control panels, and other types of electronic enclosures that require specific dimensions or mounting options.

In the automotive industry, custom aluminium profiles are used in the design of electrical systems, including the housing for batteries, power distribution units, and cooling systems. The lightweight and durable nature of aluminium makes it an ideal material for use in vehicles, where reducing weight while maintaining structural integrity is a critical consideration.

Additionally, custom aluminium profiles are used in the telecommunications and data storage industries. They can be found in the construction of racks and enclosures for servers, routers, and other communication equipment, where precise fitting and the ability to manage heat are essential for the performance and longevity of the devices.

Challenges in Customizing Aluminium Profile Electronic Fittings

While the customization of aluminium profile electronic fittings offers numerous benefits, there are also challenges to consider. One of the main challenges is the additional time and cost involved in producing custom profiles. The design and manufacturing process for custom fittings can take longer than producing standard profiles, which can affect project timelines. Additionally, custom profiles are generally more expensive due to the increased complexity of their design and production.

Another challenge is ensuring that the customized profiles meet the necessary technical specifications and performance requirements. Rigorous testing and validation processes must be conducted to ensure that the final product performs as expected under real-world conditions. Any mistakes in the design or production phase can lead to delays or the need for additional iterations, which can further increase costs.

Customization of Aluminium Profile Electronic Fittings

In conclusion, aluminium profile electronic fittings can indeed be customized to meet specific design or size requirements, providing manufacturers with a flexible and efficient solution for creating functional and reliable electronic components. The ability to modify dimensions, shapes, and features allows these fittings to be tailored to a wide range of applications across various industries. Despite the challenges associated with the customization process, the benefits of having a fitting that is perfectly aligned with the project's needs often outweigh the drawbacks. For businesses looking to optimize their products, customized aluminium profiles can offer significant advantages in terms of functionality, efficiency, and performance.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский