What are the surface treatment and appearance of aluminum die casting?

25-12-2025Introduction to Aluminum Die Casting

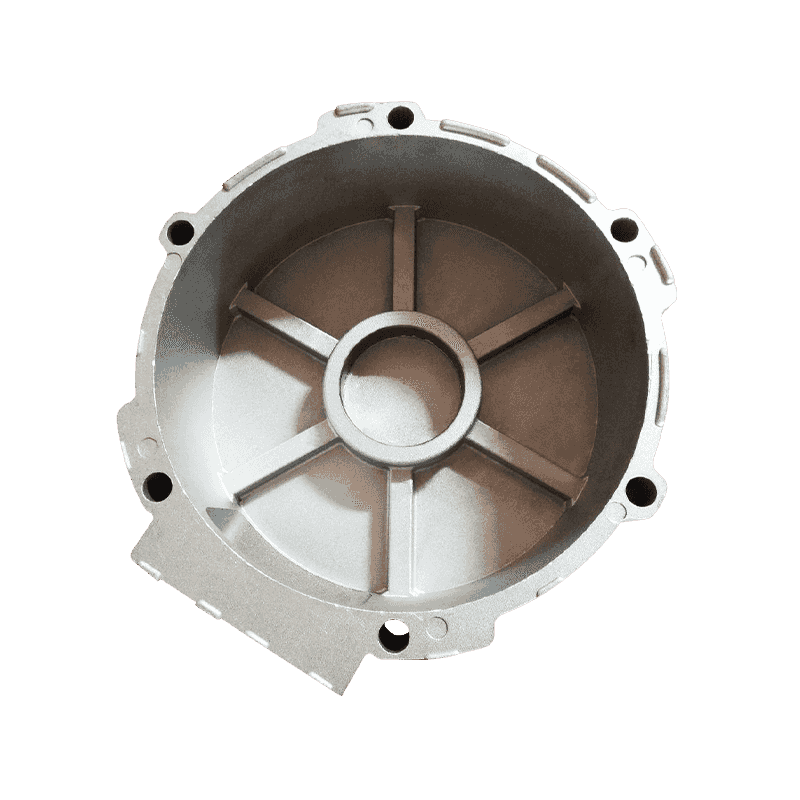

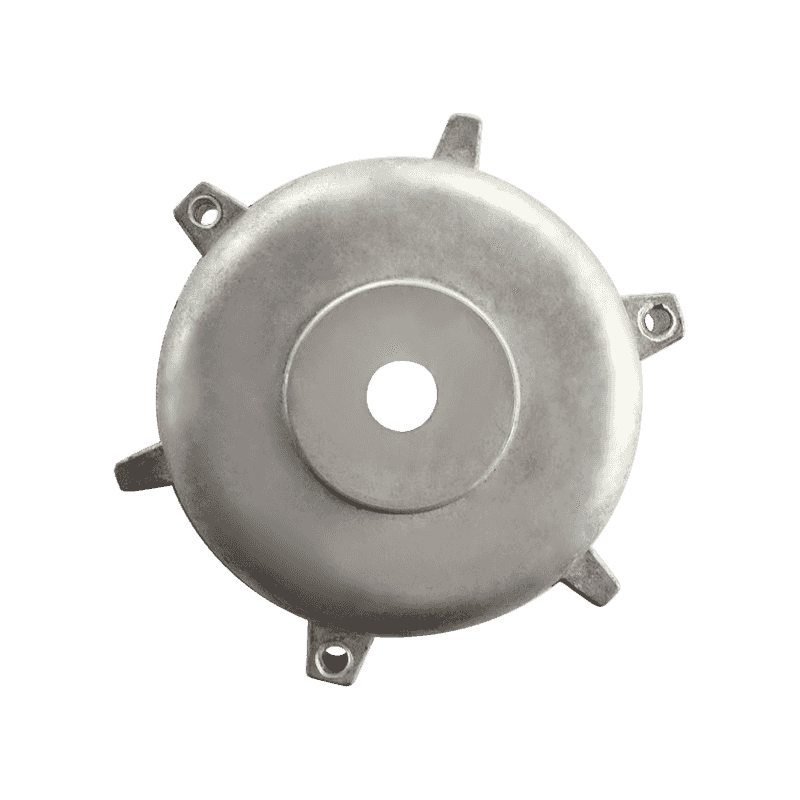

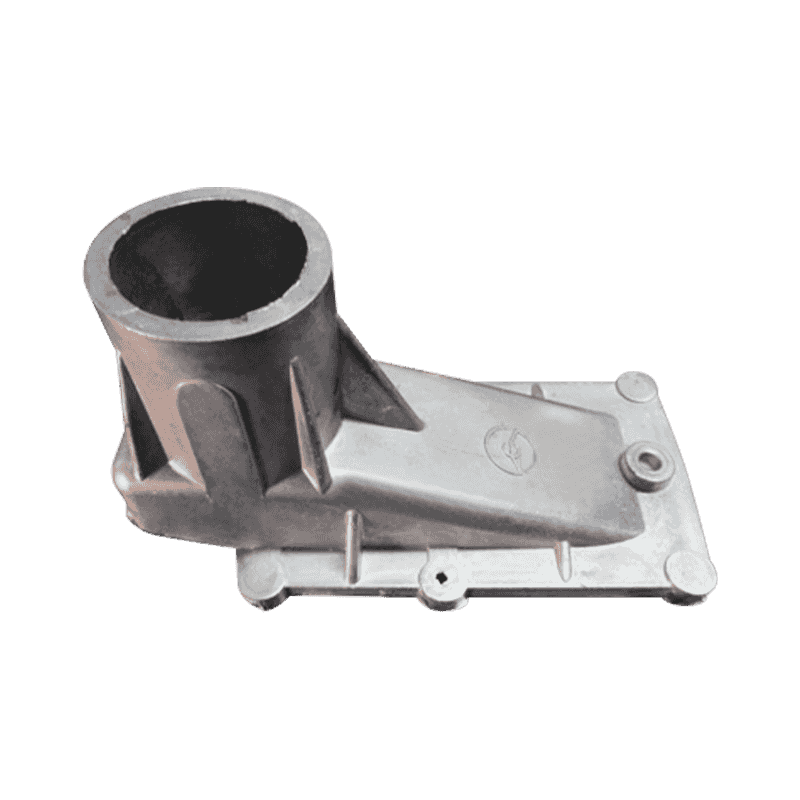

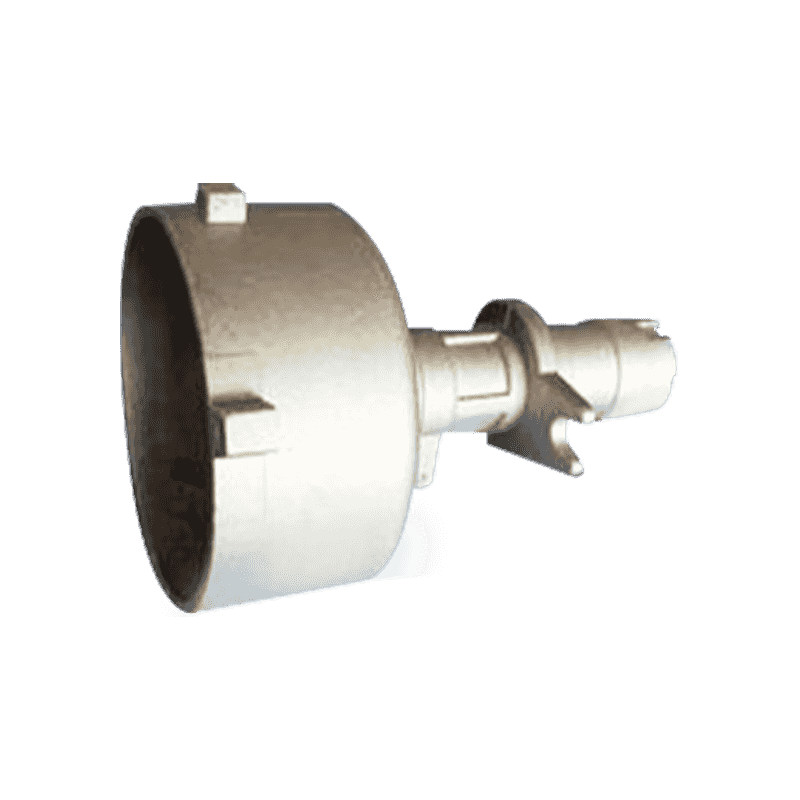

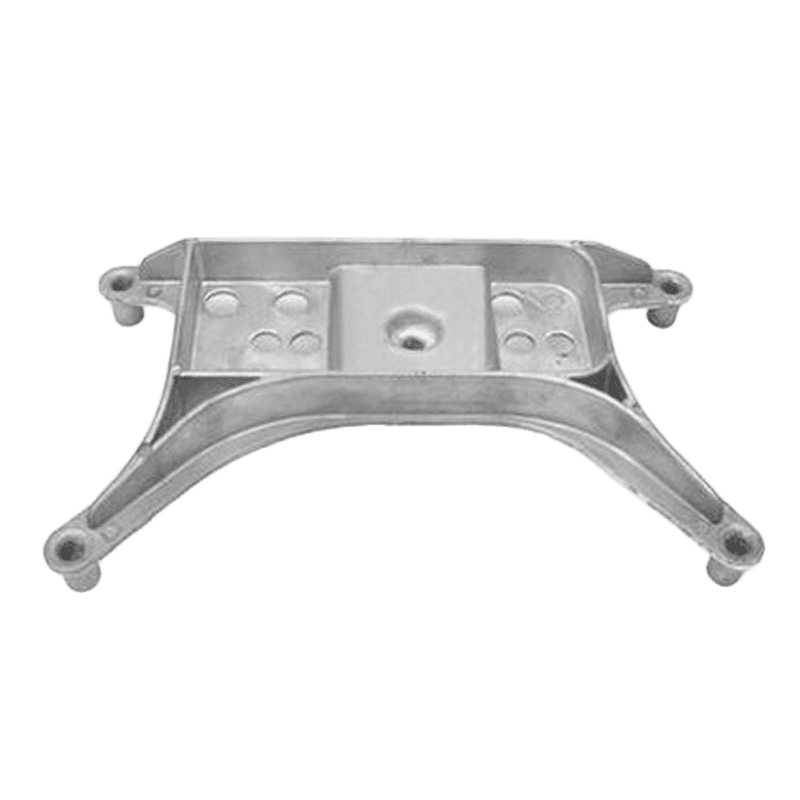

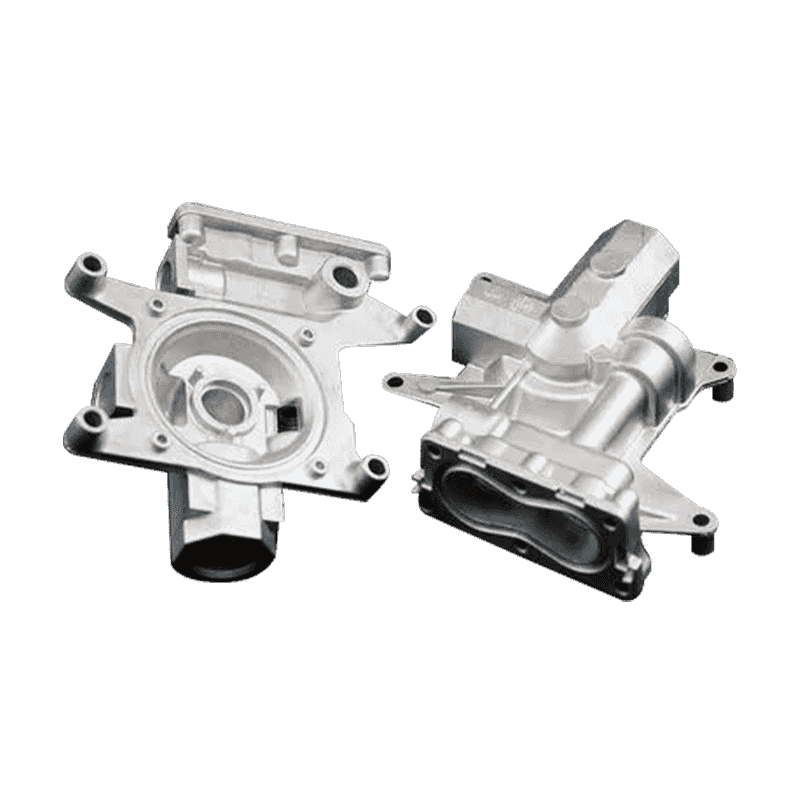

Aluminum die casting is a widely used manufacturing process that involves injecting molten aluminum into a mold to create precise, complex shapes. This process is particularly valued for its ability to produce parts with tight tolerances, high durability, and excellent surface finishes. Aluminum die-cast components are used in many industries, such as automotive, electronics, and aerospace, due to their strength, lightweight properties, and versatility. The surface treatment and appearance of aluminum die-cast products play a significant role in both their functionality and aesthetics, affecting the performance, corrosion resistance, and overall quality of the finished part.

The Importance of Surface Treatment in Aluminum Die Casting

Surface treatment is an essential part of the aluminum die casting process because it improves the final product's appearance, corrosion resistance, and durability. Aluminum, in its raw form, is prone to corrosion, particularly when exposed to moisture and other environmental factors. By applying surface treatments, manufacturers can increase the lifespan of aluminum die-cast components and enhance their aesthetic appeal. Surface treatments also serve functional purposes, such as improving wear resistance and enhancing the component's ability to withstand harsh operating conditions.

Various surface treatment methods can be used depending on the application and the desired characteristics of the final part. These treatments can range from simple processes like polishing to more complex procedures such as anodizing and powder coating. The surface treatment not only protects the aluminum casting from environmental factors but also improves its mechanical properties, making it suitable for demanding applications such as engine parts, electrical enclosures, and structural components.

Common Surface Treatments for Aluminum Die Castings

Aluminum die-castings can undergo several types of surface treatments to improve their corrosion resistance, strength, and appearance. The choice of treatment depends on the specific needs of the part and the environment in which it will be used. Some of the most common surface treatments for aluminum die castings include anodizing, powder coating, chromate conversion coating, and painting.

Anodizing Aluminum Die Castings

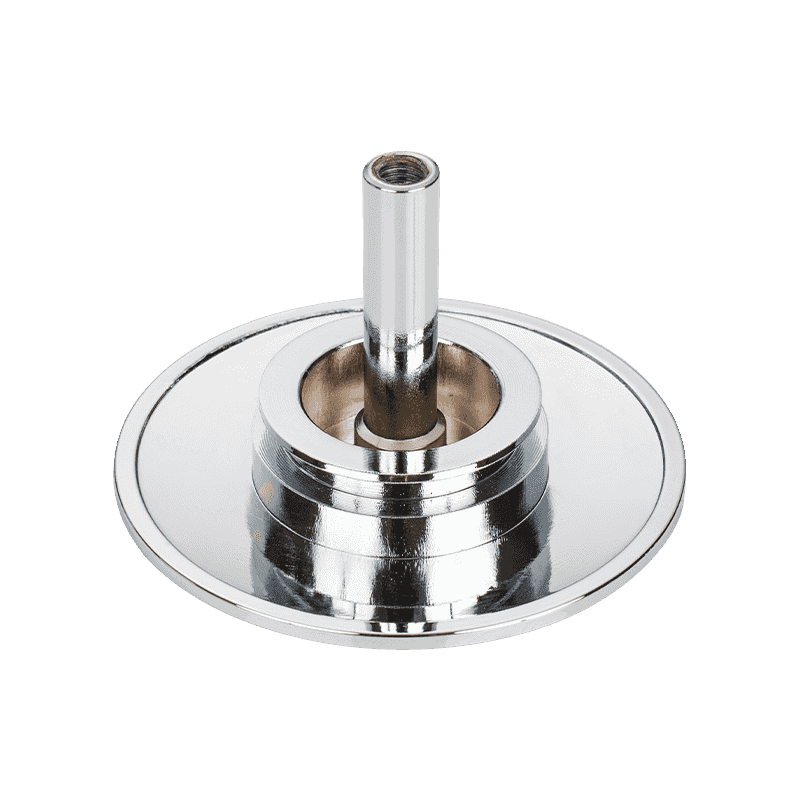

Anodizing is one of the most popular and effective surface treatments for aluminum die castings. This electrochemical process involves creating a thick oxide layer on the surface of the aluminum. The anodized layer is much harder and more durable than the base aluminum, providing excellent protection against corrosion and wear. Anodizing also enhances the appearance of aluminum by giving it a uniform, matte, or glossy finish, depending on the specific process used.

The anodized layer is porous, which allows for the easy absorption of dyes. This makes anodizing a great choice for parts that require a color finish. The process is environmentally friendly because it uses water-based solutions and does not generate harmful emissions. Anodized aluminum parts are often used in aerospace, automotive, and architectural applications due to their durability and aesthetic appeal. However, anodizing does not provide the same level of impact resistance as some other coatings, so it may not be suitable for parts that will undergo heavy mechanical stress.

Powder Coating of Aluminum Die Castings

Powder coating is another popular surface treatment for aluminum die-castings, particularly for parts that require additional protection from environmental factors. This process involves applying a dry powder, which is then cured with heat to form a durable, protective coating on the surface of the part. The powder coating process provides a smooth, even finish that is highly resistant to scratches, UV rays, and harsh weather conditions.

Powder coating can be applied in a variety of colors and finishes, from matte to glossy, allowing for greater customization of the final product's appearance. This method is especially useful for parts used in outdoor or industrial environments, where corrosion resistance and durability are critical. The process is also highly efficient, as it produces minimal waste and can be applied in a variety of thicknesses to meet the specific needs of the application.

However, the powder coating process can be more expensive and time-consuming compared to some other surface treatments, and it may not be suitable for parts that require fine detailing or intricate designs due to the thickness of the coating.

Chromate Conversion Coating

Chromate conversion coating is a chemical process that provides a thin, corrosion-resistant layer on aluminum surfaces. This treatment is often used as a primer before applying other coatings, such as paints or powder coatings. The chromate conversion process creates a thin film that offers good protection against corrosion, particularly in environments where the part is exposed to moisture and chemicals.

In addition to its protective properties, chromate conversion coatings can improve the appearance of aluminum die castings by providing a matte or metallic finish. This process is commonly used in the aerospace and automotive industries, where components are subjected to harsh environments and must be protected from corrosion. While chromate conversion coatings provide good corrosion resistance, they are not as durable as anodizing or powder coating and may need to be reapplied periodically to maintain the part's protective properties.

Painting Aluminum Die Castings

Painting is one of the simplest and most cost-effective surface treatments for aluminum die-castings. It provides a protective layer that can help prevent corrosion and wear, while also improving the appearance of the part. The paint used on aluminum die castings can be either liquid-based or powder-based, depending on the specific needs of the part and the application.

Paint coatings offer a wide range of colors and finishes, making it an ideal choice for parts that require a specific aesthetic. However, while painting can enhance the appearance of the part, it may not provide the same level of long-term protection as more advanced surface treatments such as anodizing or powder coating. Over time, painted surfaces can wear off, especially in parts that are exposed to heavy mechanical stress or extreme weather conditions. In addition, the adhesion of paint to aluminum can sometimes be problematic, requiring additional surface preparation to ensure proper bonding.

Appearance of Aluminum Die Castings

The appearance of aluminum die-castings is influenced by several factors, including the casting process itself, the surface treatment applied, and the finish of the final part. Aluminum die-casting is known for its ability to produce parts with fine details, smooth surfaces, and tight tolerances, which makes it ideal for both functional and aesthetic applications.

The raw appearance of an aluminum die-cast part is often somewhat matte and unrefined, with visible mold lines and surface imperfections. These imperfections can be minimized through post-casting processes such as polishing, grinding, and sandblasting. However, many aluminum die-cast parts undergo surface treatments like anodizing or powder coating to improve their appearance further. These treatments not only provide a more uniform finish but also allow for the introduction of color, which can be important for design and branding purposes.

Anodizing, for example, results in a consistent, metallic finish that can range from a natural silver color to various shades of color, depending on the dyes used. Powder coating offers a wide range of finishes, from matte to glossy, and can also be textured to provide a more industrial or rugged look. Painting can be used to achieve vibrant colors and intricate patterns, but it generally results in a less durable finish compared to anodizing or powder coating.

The final appearance of an aluminum die-cast part is also affected by the quality of the mold and the die-casting process itself. High-quality molds result in smoother parts with fewer imperfections, while lower-quality molds may lead to more visible defects that require additional finishing work. As with all manufacturing processes, the consistency and precision of the die-casting process are essential in achieving parts that meet both aesthetic and functional standards.

Benefits of Surface Treatment in Aluminum Die Castings

Surface treatments provide numerous benefits to aluminum die-cast parts, improving their functionality and aesthetic appeal. One of the most significant advantages of surface treatment is increased corrosion resistance. Aluminum is highly susceptible to oxidation when exposed to moisture and air, which can lead to the formation of rust and the degradation of the material. Anodizing, powder coating, and chromate conversion coatings can protect the aluminum surface, ensuring that the part maintains its strength and appearance over time.

In addition to corrosion resistance, surface treatments also improve the mechanical properties of aluminum die-cast parts. For example, anodizing creates a harder surface that is more resistant to wear and scratching, while powder coating adds an additional layer of protection against impact and abrasion. These enhanced properties make aluminum die-cast parts more suitable for use in demanding environments, such as automotive engines, outdoor equipment, and industrial machinery.

Surface treatments can also provide an opportunity for branding and design. By applying different coatings or finishes, manufacturers can create parts that not only perform well but also meet the visual expectations of their customers. Whether it is a sleek, metallic finish for a high-end consumer product or a rugged, matte coating for an industrial application, the appearance of aluminum die-cast parts can be customized to meet specific needs.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский