What standards can lead die casting achieve in terms of dimensional accuracy and surface finish?

22-10-2025Dimensional Accuracy in Lead Die Casting

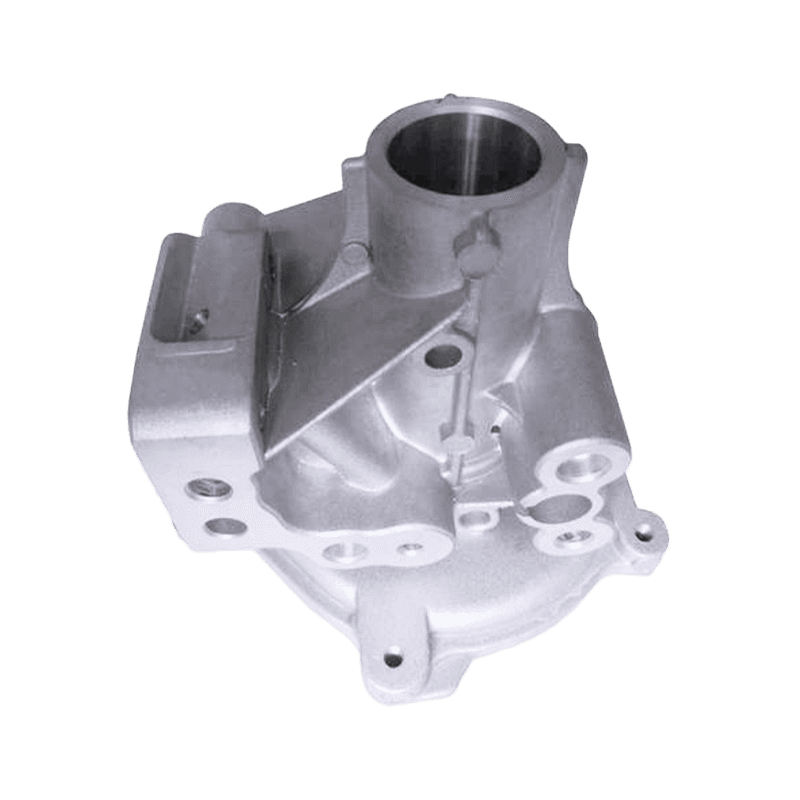

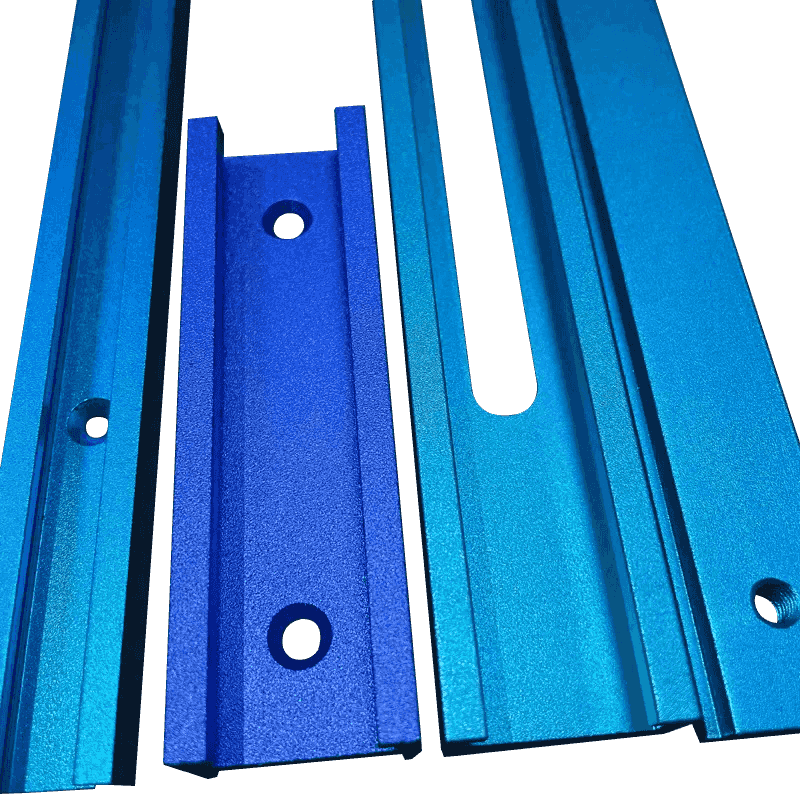

Lead die casting is known for its ability to achieve high dimensional precision, which is crucial in industries requiring consistent part geometry and fit. The dimensional accuracy depends on multiple factors such as mold design, injection pressure, cooling rate, and die temperature control. In standard industrial practice, lead die-cast components can typically meet tolerance levels within ±0.05 mm to ±0.1 mm for smaller dimensions and slightly larger ranges for bigger components. This precision allows lead die casting to be suitable for applications where tight tolerances and repeatability are critical, such as electric vehicle die casting, fishing gear die-casting, and machinery die casting.

Factors Influencing Dimensional Accuracy

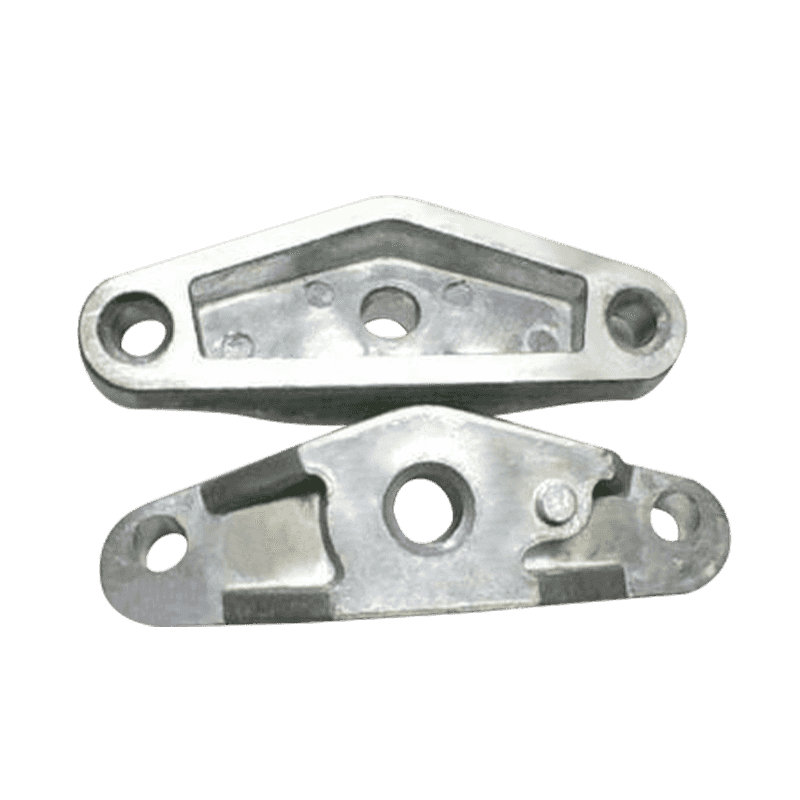

Dimensional accuracy in lead die casting is influenced by alloy composition, die wear, and process stability. Lead-based alloys exhibit good fluidity, enabling them to fill fine cavities with minimal distortion. However, variations in cooling rates can cause minor shrinkage or warping. Advanced mold design with proper venting and gating systems helps minimize dimensional deviations. Additionally, automation in die casting equipment allows precise control of injection parameters, ensuring consistency across production batches. Regular calibration and maintenance of machinery also contribute to maintaining stable dimensional standards during long-term manufacturing.

Surface Finish Characteristics

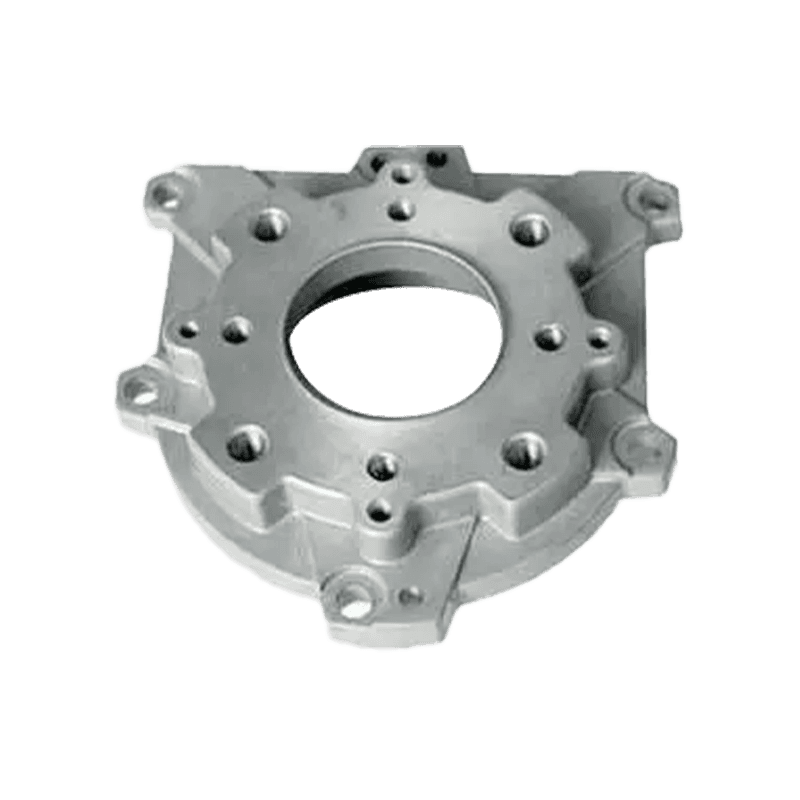

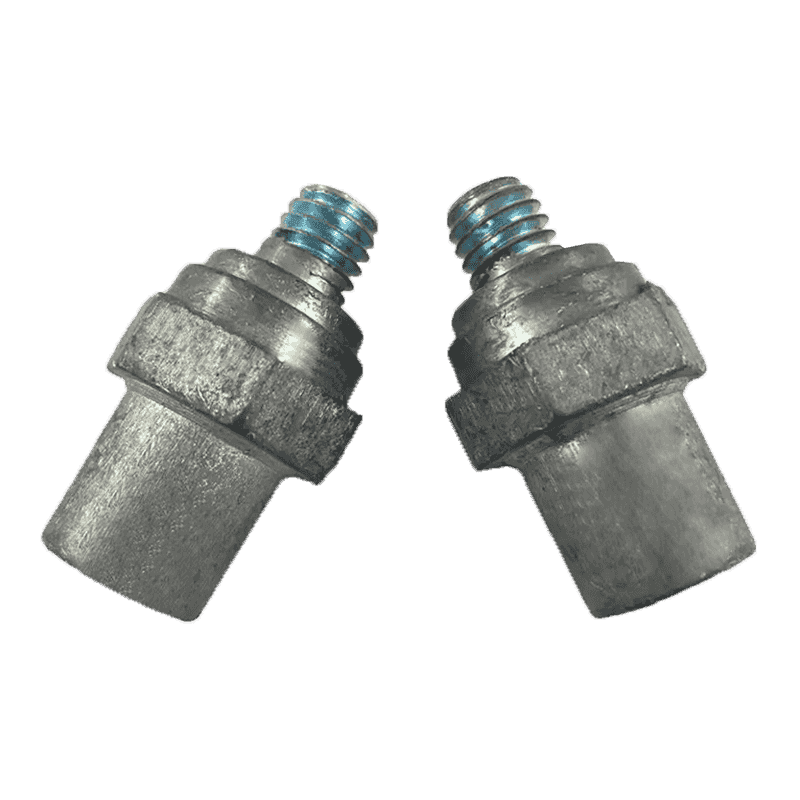

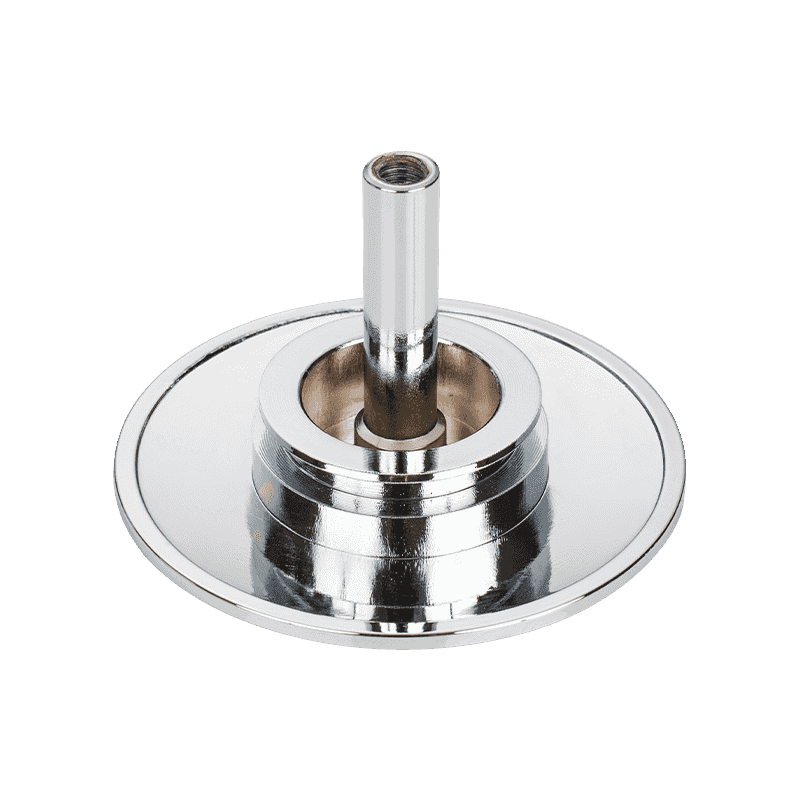

The surface finish of lead die-cast parts depends largely on the mold surface quality and processing conditions. A properly polished die can produce components with a surface roughness (Ra) as low as 0.8 to 1.6 micrometers, which is suitable for most industrial applications. When higher cosmetic or sealing quality is required, secondary finishing processes such as shot blasting, polishing, or electroplating can be applied. This ensures that the final product meets functional and visual expectations without compromising mechanical performance. In precision equipment manufacturing, particularly in fishing gear die-casting, smooth surface finishes are essential to reduce friction and improve component performance.

Comparative Tolerances in Different Applications

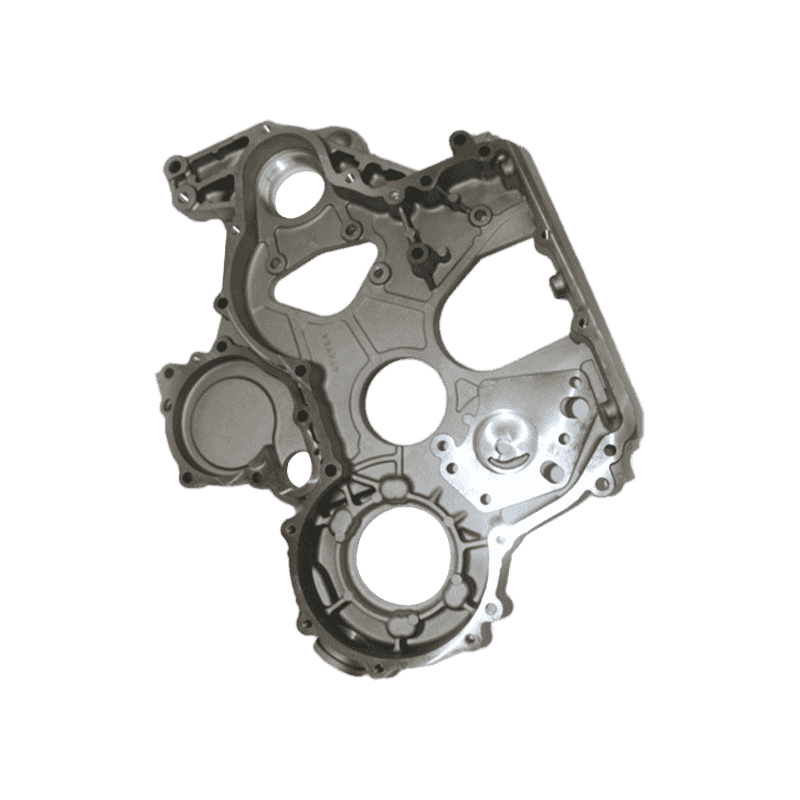

Different industries impose varying tolerance requirements depending on the intended application. For instance, in electric vehicle die casting, tighter tolerances are often required to ensure compatibility between electronic housings or thermal management components. Machinery die casting, on the other hand, may allow slightly broader tolerances if parts are subject to secondary machining or assembly adjustments. The following table summarizes the general dimensional accuracy ranges observed in various applications of lead die casting.

| Application Field | Typical Dimensional Tolerance | Surface Roughness (Ra) | Post-Processing Requirement |

|---|---|---|---|

| Electric Vehicle Die Casting | ±0.05 mm - ±0.08 mm | 0.8 – 1.2 μm | Often requires polishing or anodizing |

| Fishing Gear Die-Casting | ±0.06 mm - ±0.1 mm | 1.0 – 1.6 μm | Occasional electroplating for corrosion protection |

| Machinery Die Casting | ±0.08 mm - ±0.15 mm | 1.6 – 3.2 μm | Machining or coating based on use |

Process Optimization and Measurement Techniques

Achieving and maintaining dimensional accuracy requires precise measurement and quality control. Coordinate Measuring Machines (CMM) and laser scanning systems are widely used to verify the dimensional stability of die-cast parts. These systems allow for non-contact measurement of complex geometries, ensuring that deviations from the design model remain within acceptable limits. Statistical Process Control (SPC) techniques are also applied in die casting production lines to monitor trends in part dimensions and identify potential process drifts early. The integration of digital measurement tools with production management systems allows for real-time corrections, reducing scrap rates and maintaining consistent quality.

Influence of Alloy Composition on Precision

Lead-based alloys possess specific properties that make them suitable for precise die casting. The presence of tin and antimony enhances strength and wear resistance, while maintaining good fluidity. The alloy composition determines the casting’s shrinkage rate, which directly affects dimensional accuracy. When used in electric vehicle die casting, alloy control becomes particularly important because the parts often require tight tolerances for sealing and heat dissipation. Similarly, fishing gear die-casting benefits from alloys with lower shrinkage to ensure precise fitment of moving components, while machinery die casting utilizes alloys that balance mechanical strength and casting ease.

Die Design and Its Role in Achieving Accuracy

The die design plays a critical role in determining the final dimensional outcome of a casting. Elements such as parting lines, ejector pin locations, and cooling channels must be carefully designed to reduce stress concentration and warping. Uniform temperature control within the die ensures that the molten lead cools evenly, preventing local shrinkage or distortion. In advanced applications like machinery die casting, computer-aided engineering (CAE) simulations are used to predict metal flow and solidification behavior, optimizing the die structure before manufacturing begins. These design considerations contribute significantly to achieving reliable accuracy and high-quality surface finish.

Surface Finish Enhancement through Post-Treatments

Post-treatment processes such as polishing, shot blasting, and coating are commonly employed to improve the surface finish of lead die-cast components. These processes not only enhance appearance but also reduce surface porosity, improving corrosion resistance and paint adhesion. For example, electric vehicle die casting parts may undergo powder coating to protect against environmental exposure, while fishing gear die-casting components often receive nickel plating to resist saltwater corrosion. Machinery die casting products may also undergo machining to refine surface smoothness for assembly or sealing purposes. The combination of precise casting and effective finishing ensures that each part meets both functional and aesthetic expectations.

Dimensional Stability under Operational Conditions

After production, dimensional stability remains an important consideration, especially for parts subjected to temperature variations or mechanical loads. Lead die-cast components generally exhibit good stability due to the material’s resistance to thermal expansion. However, excessive heat exposure during operation can cause minor deformation if the alloy composition or heat treatment process is inadequate. In electric vehicle die casting, thermal stability is critical for battery enclosures and electronic housings. Similarly, fishing gear die-casting components must maintain dimensional stability to ensure smooth operation under varying water temperatures. Maintaining stable production conditions during die casting contributes to minimizing such variations.

Comparison Between Lead Die Casting and Other Metal Casting Methods

Lead die casting is often compared with aluminum and zinc die casting in terms of precision and finish. While aluminum alloys are lighter and commonly used in electric vehicle die casting, lead offers better dimensional repeatability due to its low melting point and good flow characteristics. Zinc die casting, on the other hand, achieves a similar surface finish but requires higher casting pressure. The following table outlines a general comparison among these materials in relation to dimensional accuracy and surface finish.

| Material Type | Melting Point (°C) | Dimensional Tolerance (mm) | Surface Roughness (Ra μm) | Typical Application |

|---|---|---|---|---|

| Lead Alloy | 327°C | ±0.05 – ±0.1 | 0.8 – 1.6 | Fishing gear die-casting, machinery die casting |

| Aluminum Alloy | 660°C | ±0.08 – ±0.15 | 1.2 – 2.5 | Electric vehicle die casting |

| Zinc Alloy | 420°C | ±0.05 – ±0.08 | 0.8 – 1.2 | Consumer products, hardware parts |

Inspection and Quality Control Practices

Inspection methods for ensuring dimensional accuracy and surface quality include visual examination, dimensional measurement, and surface roughness testing. Non-destructive testing (NDT) methods such as X-ray and ultrasonic inspection can detect internal defects that may affect stability and precision. For high-value components used in electric vehicle die casting, quality control teams perform comprehensive dimensional mapping to ensure all parts meet strict tolerances. Regular monitoring of tool wear, die temperature, and injection parameters ensures that consistent accuracy is maintained over time. Implementing these inspection standards supports long-term reliability and reduces waste.

Process Stability and Repeatability

The ability to reproduce identical parts over multiple production cycles defines process stability in lead die casting. Automated systems with programmable controls ensure that parameters such as injection speed, pressure, and temperature remain within set limits. Real-time monitoring and feedback systems further improve process repeatability. This consistency is essential in sectors such as machinery die casting, where parts must fit together with minimal variation. Stable production conditions also reduce rework rates, helping manufacturers achieve predictable costs and timelines without compromising accuracy or surface finish.

Applications Requiring High Accuracy and Smooth Finish

Lead die casting is widely used in fields that require high dimensional consistency and smooth surface textures. Electric vehicle die casting components benefit from this technology due to the need for precision in electronic housings and battery cases. Fishing gear die-casting requires accurate fitting to ensure mechanical efficiency and durability under load. Machinery die casting applications include housings, gears, and valves, where accurate dimensions and low surface roughness enhance performance and assembly efficiency. These applications demonstrate how lead die casting supports diverse industrial requirements through precision and consistency.

Integration of CNC Machining in Finishing Processes

To further enhance dimensional accuracy, lead die-cast components often undergo CNC machining as a secondary process. CNC machining allows the refinement of surfaces and tolerance control beyond the limits of the casting process. This integration is especially common in electric vehicle die casting and machinery die casting, where complex geometries and critical alignment features are required. The combination of die casting and CNC machining provides both cost efficiency and superior dimensional precision, meeting the evolving demands of modern manufacturing sectors.

Future Trends in Dimensional and Surface Quality Control

The future of lead die casting lies in digital manufacturing and automation. Technologies such as 3D mold scanning, predictive simulation, and AI-based quality control are improving the ability to predict and control deviations. Enhanced die materials and coatings also extend mold life, maintaining surface finish consistency over longer production runs. As industries like electric vehicle die casting and fishing gear die-casting continue to evolve, the emphasis on accuracy and environmental efficiency will drive further innovation in lead die casting technology and production systems.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский