Are aluminium profile brackets suitable for dynamic loads or vibration environments?

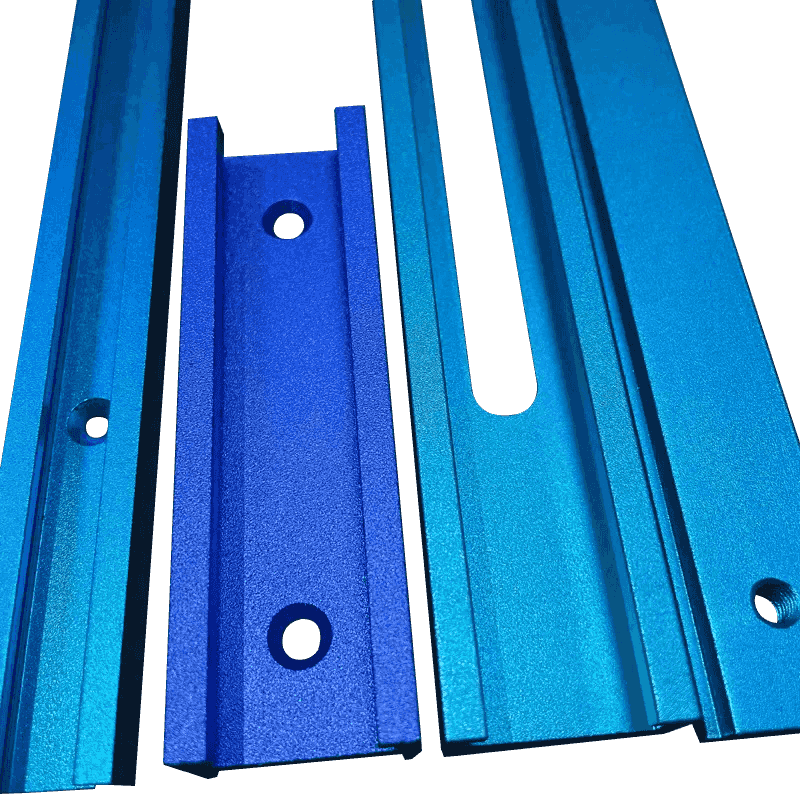

15-10-2025Overview of Aluminium Profile Brackets

Aluminium profile brackets are widely used components in various structural and mechanical applications due to their lightweight, corrosion resistance, and ease of installation. These brackets serve as connectors and supports for aluminium profiles, providing stability and alignment for frames, assemblies, and machinery. Their versatility makes them popular in industries such as automation, material handling, and construction.

Mechanical Properties Relevant to Dynamic Loads

The suitability of aluminium profile brackets for dynamic loads depends on their mechanical properties, including tensile strength, yield strength, and fatigue resistance. Aluminium alloys commonly used for brackets provide moderate strength with good elasticity, allowing them to withstand moderate vibration and cyclic loading without permanent deformation. The design of the bracket, including thickness, geometry, and reinforcement features, also affects its ability to endure dynamic stresses over time.

Impact of Vibration Environments

In environments where vibration is present, brackets may experience repeated stress cycles, which can lead to fatigue failure if not properly accounted for. Aluminium profile brackets generally perform well under low to moderate vibration conditions due to their lightweight structure and elastic deformation capacity. However, continuous high-frequency vibration or heavy dynamic loads may require additional support, reinforced bracket designs, or the use of vibration-damping elements to maintain structural integrity and prevent loosening of fasteners.

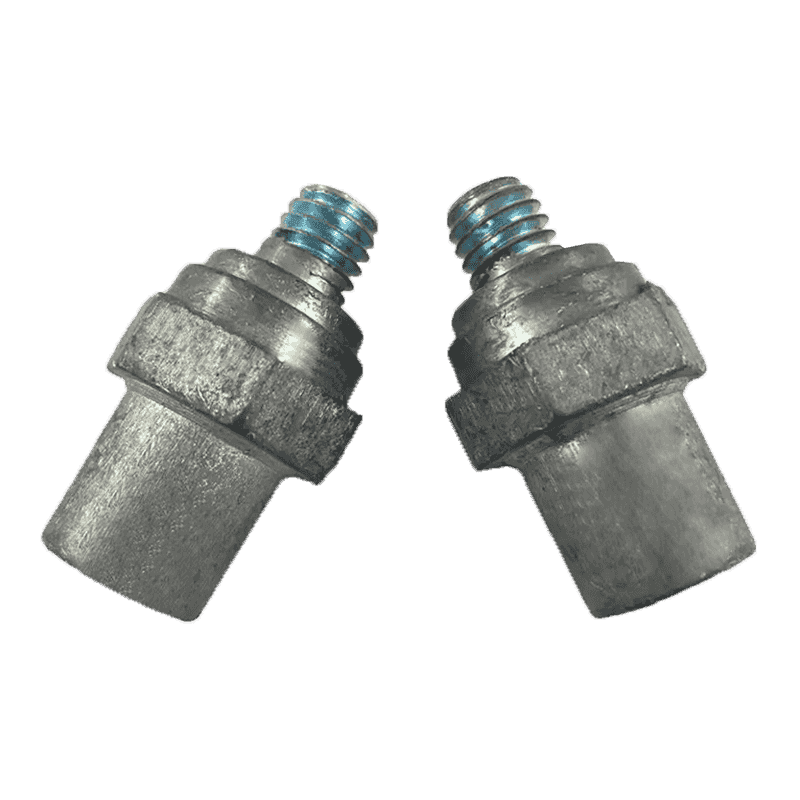

Design Considerations for Dynamic Applications

When using aluminium profile brackets in dynamic or vibration-prone environments, several design factors are important. Selecting brackets with increased wall thickness or gussets can improve load-bearing capacity. The use of multiple brackets to distribute forces evenly reduces stress concentration. Fasteners must be properly torqued and, if necessary, secured with locking mechanisms to prevent loosening under vibration. Proper alignment of the aluminium profiles ensures that the brackets carry loads as intended, minimizing additional stress points.

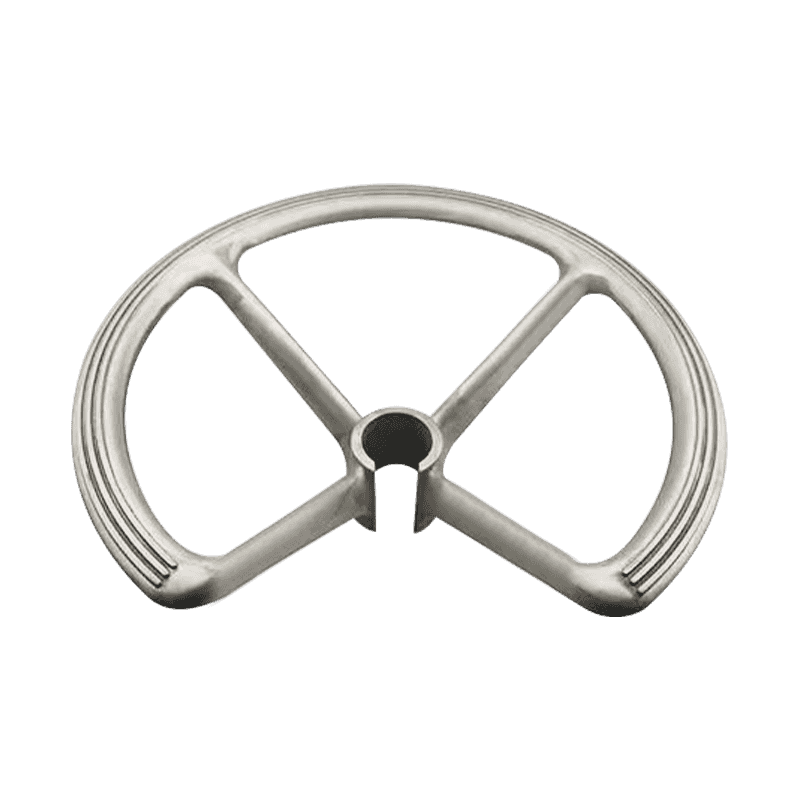

Comparison of Bracket Types for Vibration Resistance

| Bracket Type | Material | Recommended Dynamic Load | Vibration Resistance Notes |

|---|---|---|---|

| Standard Aluminium Bracket | Aluminium Alloy 6063 | Moderate | Suitable for low-frequency vibration; may require reinforcement for high-frequency environments |

| Reinforced Aluminium Bracket | Aluminium Alloy 6061 | High | Enhanced gussets or thicker walls improve resistance to dynamic loads and vibration |

| Brackets with Vibration Dampers | Aluminium + Elastomer Pads | Moderate to High | Vibration-damping inserts reduce fatigue and fastener loosening under repeated loads |

Maintenance and Inspection for Vibration Applications

Aluminium profile brackets in dynamic environments require periodic inspection to ensure that they remain secure and intact. Fasteners should be checked for tightness and signs of wear, and brackets should be inspected for cracks or deformation caused by repeated loading. In applications with significant vibration, monitoring systems can help detect early signs of fatigue or movement, allowing preventive maintenance to be conducted before failure occurs.

Environmental Factors Affecting Performance

Environmental conditions, such as temperature fluctuations, humidity, and exposure to chemicals, can influence the performance of aluminium profile brackets. High temperatures can reduce aluminium strength, while corrosive environments may accelerate surface degradation, particularly at contact points or interfaces. Using anodized or coated aluminium brackets can provide additional protection and maintain mechanical properties under challenging environmental conditions.

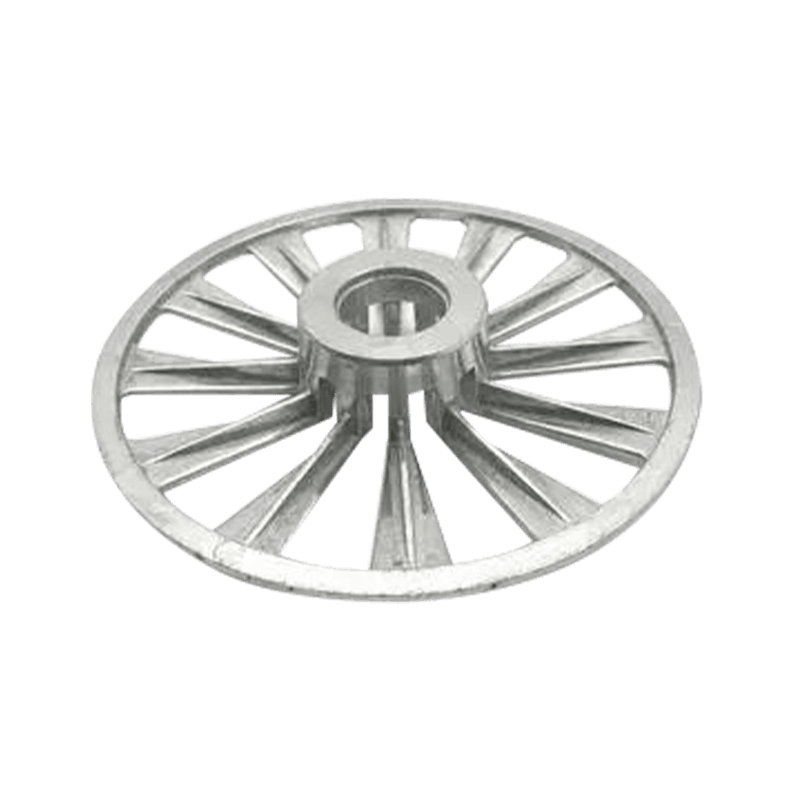

Integration with Other Components

Aluminium profile brackets are often part of a larger assembly that includes aluminium profiles, fasteners, and functional equipment. Ensuring that the entire system can handle dynamic loads is critical. Proper selection of profiles with suitable cross-sectional strength, combined with correctly installed brackets, enhances overall stability. In some cases, supplementary components such as vibration isolators or shock absorbers may be integrated to reduce stress on the brackets and prolong their service life.

Engineering Guidelines and Standards

Adherence to engineering guidelines and standards is important when using aluminium profile brackets in dynamic applications. Standards provide recommended load ratings, testing procedures, and design considerations that help ensure safety and reliability. Manufacturers often provide specifications for maximum static and dynamic loads, and these should be considered during the design phase to avoid overloading brackets in operational conditions.

Best Practices for Long-Term Reliability

For applications involving vibration or dynamic loading, best practices include selecting reinforced brackets when needed, ensuring proper torque of fasteners, distributing loads across multiple brackets, and using protective coatings or vibration-damping materials. Routine inspections and maintenance contribute to early detection of wear or damage, preventing unexpected failures. Documenting installation and maintenance activities supports long-term reliability and provides reference for future upgrades or modifications.

Conclusion on Suitability

Aluminium profile brackets can perform adequately in dynamic load and vibration environments if proper design, material selection, installation, and maintenance practices are followed. Reinforced designs, vibration-damping elements, and attention to environmental conditions enhance their capability to maintain structural integrity. By integrating these considerations, aluminium profile brackets provide reliable support in applications requiring resistance to mechanical stresses and continuous vibrations.

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский