Introduction to Aluminum Extrusion and Machining Processes Aluminum extrusion and machining are widely used techniques in the manufacturing of aluminu...

Read MoreCustom Sanitary Ware & Plating Products Manufacturers

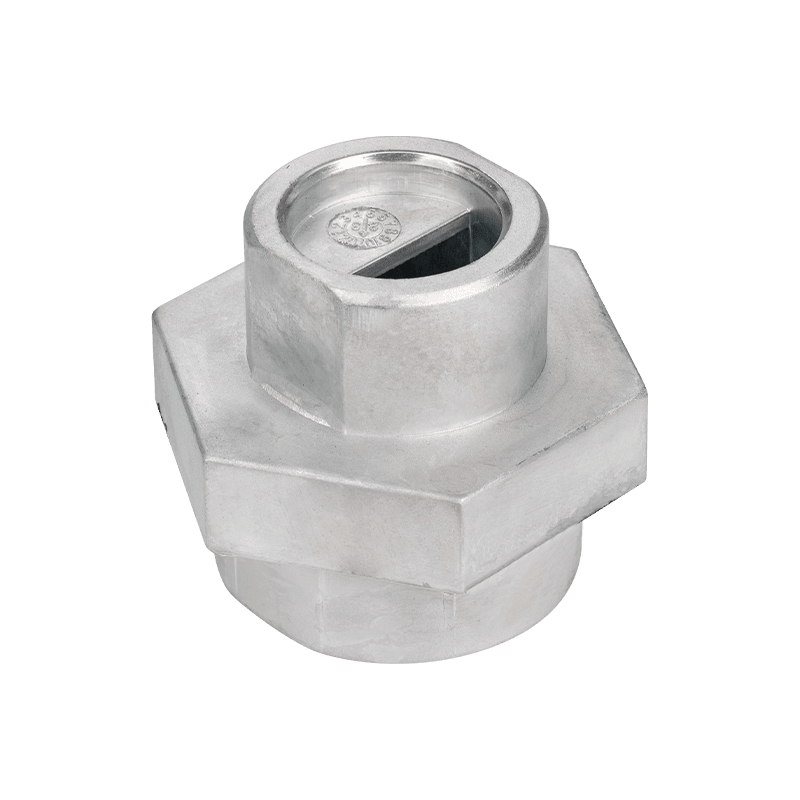

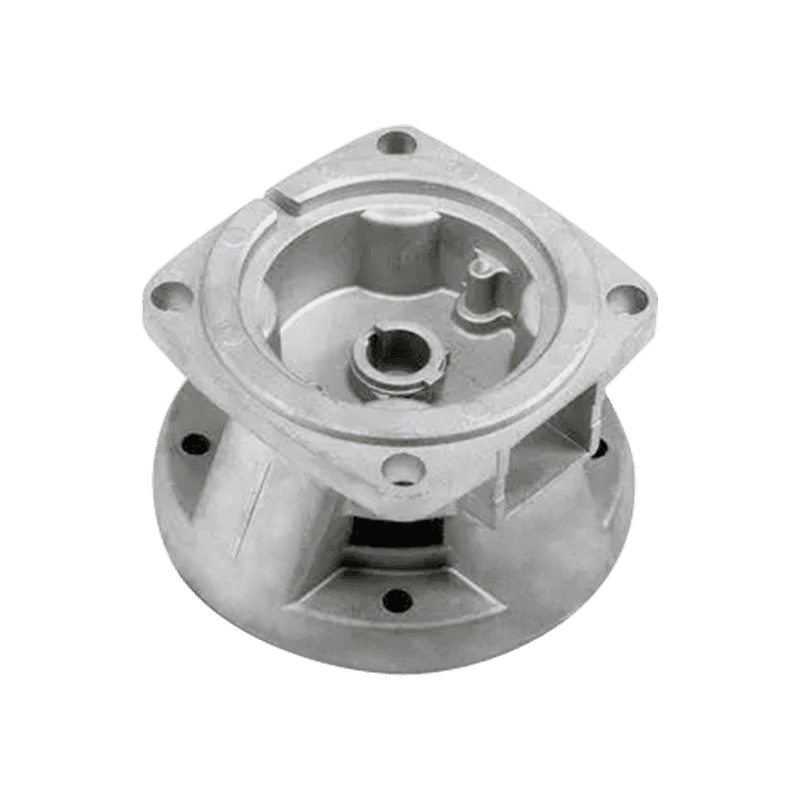

Sanitary Ware & Plating Products are an indispensable part of modern home decoration. Bathroom appliances cover a variety of wash basins, bathtubs, toilets, shower equipment, etc., while electroplating products refer to products that use electrochemical methods to plate metal on the surface of other materials.

Bathroom appliances are an important part of sanitary facilities, and their design and quality are directly related to people's quality of life and health. Modern bathroom appliances not only have basic functions such as providing cleaning, drainage and water supply, but also pay more attention to humanized design and environmental protection performance. Designers have innovated the appearance and function of bathroom appliances to make them more in line with user needs and aesthetics. At the same time, bathroom appliances also pay attention to environmental protection performance, using water-saving technology and environmentally friendly materials to reduce the impact on the environment.

Electroplating products are a common decorative material that can give the surface of other materials the appearance and performance of metal. The electroplating process usually includes steps such as cleaning, pickling, electrolytic plating and post-treatment. During the cleaning and pickling process, impurities and oxide layers can be removed, providing a good foundation for subsequent electrolytic plating. During the electrolytic plating process, metal ions can form a uniform and dense metal film on the surface of other materials, thus providing wear resistance, corrosion resistance and aesthetic effects. The post-processing process includes polishing, cleaning and packaging to ensure the quality and appearance of the electroplated products.

| 1. Drawings or Samples | We get the drawings or samples from customers. |

| 2. Drawings Confirmation | We will draw the 3D drawings according to the customers' 2D drawings or samples, and send the 3D drawings to customers for confirmation. |

| 3. Quotation | We will quote after getting the customers' confirmation, or quote directly according to customers' 3D drawings. |

| 4. Making Moulds/Patterns | We will make molds or pattens after getting the mold orders from the customers. |

| 5. Making Samples | We will make real samples using the molds and send them to customers for confirmation. |

| 6. Mass Producing | We will produce the products after getting the customers' confirmation and orders. |

| 7. Inspection | We will inspect the products by our inspectors or ask the customers to inspect together with us when finished. |

| 8. Shipment | We will ship the goods to the customers after getting the inspection result and the customers' confirmation. |

| Process: | 1) Die Casting / Profile Extrusion |

| 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading | |

| 3) Surface Treating | |

| 4) Inspection and Packaging | |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. |

| 2) Aluminum Alloys Profile Extrusion: 6061, 6063 | |

| 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. | |

| Surface Treatment: | Polishing |

| Shot Blasting | |

| Sandblasting | |

| Powder Coating | |

| Anodizing | |

| Chrome Plating | |

| Passivation | |

| E-coating | |

| T-coating | |

| etc. | |

| Tolerance: | +/-0.01mm |

| Weight Per Unit: | 0.01-5KG |

| Order Lead Time: | 20-45 Days (According to the Quantity and Complexity of the Product 1 |

| 1. Drawings or Samples | We get the drawings or samples from customers. |

| 2. Drawings Confirmation | We will draw the 3D drawings according to the customers' 2D drawings or samples, and send the 3D drawings to customers for confirmation. |

| 3. Quotation | We will quote after getting the customers' confirmation, or quote directly according to customers' 3D drawings. |

| 4. Making Moulds/Patterns | We will make molds or pattens after getting the mold orders from the customers. |

| 5. Making Samples | We will make real samples using the molds and send them to customers for confirmation. |

| 6. Mass Producing | We will produce the products after getting the customers' confirmation and orders. |

| 7. Inspection | We will inspect the products by our inspectors or ask the customers to inspect together with us when finished. |

| 8. Shipment | We will ship the goods to the customers after getting the inspection result and the customers' confirmation. |

| Process: | 1) Die Casting / Profile Extrusion |

| 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading | |

| 3) Surface Treating | |

| 4) Inspection and Packaging | |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. |

| 2) Aluminum Alloys Profile Extrusion: 6061, 6063 | |

| 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. | |

| Surface Treatment: | Polishing |

| Shot Blasting | |

| Sandblasting | |

| Powder Coating | |

| Anodizing | |

| Chrome Plating | |

| Passivation | |

| E-coating | |

| T-coating | |

| etc. | |

| Tolerance: | +/-0.01mm |

| Weight Per Unit: | 0.01-5KG |

| Order Lead Time: | 20-45 Days (According to the Quantity and Complexity of the Product 1 |

-

-

In the auto world, not everything that moves is loud. Sometimes the biggest changes come from something you barely notice, like the parts inside the e...

Read More -

Introduction to Zinc Die Casting Zinc die casting is a widely used manufacturing process for producing parts that require high precision, complex shap...

Read More -

Introduction to Aluminum Alloy Die-Casting in Automotive Applications Aluminum alloy die-casting has become a widely used manufacturing process in the...

Read More

Introduction to Sanitary Ware & Plating Products

Materials and Manufacturing Processes

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский