How to choose suitable materials for lead die casting to improve casting accuracy and strength?

16-07-2025Basic properties of lead and its alloys

Lead is a metal with high density and low melting point, and has good corrosion resistance and processing properties. Pure lead has low mechanical strength and is easy to deform, making it difficult to meet the strength and precision requirements of certain industrial applications. Therefore, in the lead die-casting process, alloying elements are usually added to improve the comprehensive performance of the casting. Selecting the right lead alloy material is an important part of improving the precision and strength of the casting.

Effect of alloying elements on the performance of lead die-casting materials

The addition of different alloying elements to lead will affect the mechanical properties, fluidity, and solidification characteristics of the material. Tin (Sn), antimony (Sb), and copper (Cu) are common lead alloying elements. Tin can improve the strength and hardness of the alloy; antimony enhances the wear resistance and mechanical properties of the material; copper helps to improve the corrosion resistance and structural stability of the alloy. Reasonable adjustment of the alloy composition can effectively improve the overall performance of the casting.

Flowability and solidification properties of lead alloys

The process of lead die-casting requires the material to have good fluidity to ensure that the liquid metal can fully fill the complex shape of the mold while maintaining dimensional stability. Excessive alloy content may lead to an increase in melting point, reduce fluidity, and increase the risk of casting defects. Solidification speed and method also directly affect the microstructure and mechanical properties of castings. Appropriate alloy ratio can balance fluidity and solidification properties to ensure the accuracy of castings.

Effect of material selection on casting strength

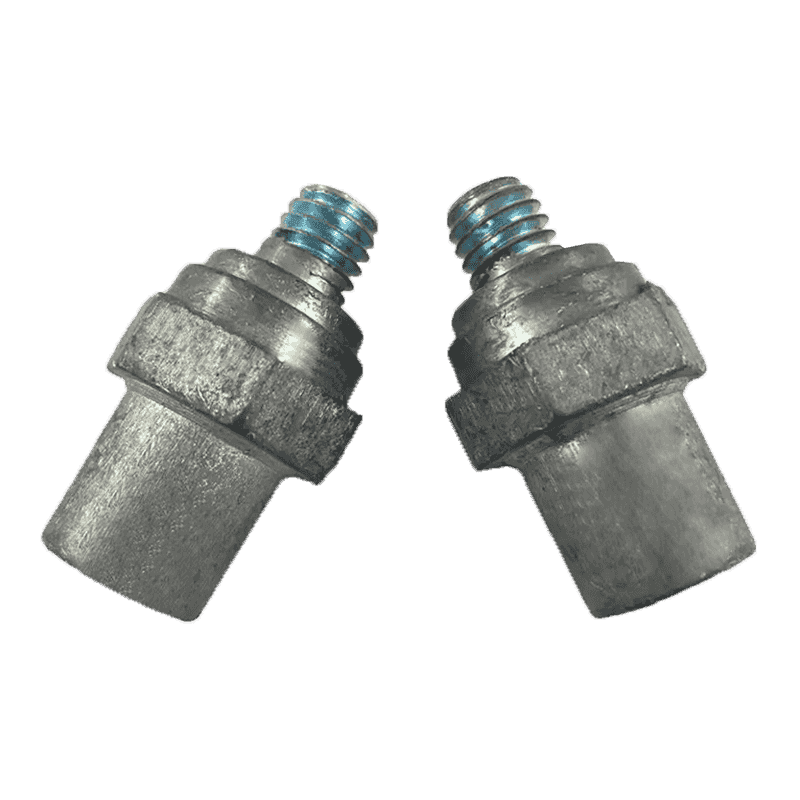

The strength of castings is mainly affected by material composition and internal organizational structure. Adding antimony and tin can form strengthening phases, improve the yield strength and hardness of the alloy, and help to withstand mechanical loads. Although the addition of copper generally does not exceed a certain proportion, it can improve corrosion resistance and overall toughness. The material should take into account processing performance and cost-effectiveness on the basis of ensuring strength.

Importance of material purity and impurity control

Impurities in materials can cause casting defects such as pores, inclusions and cracks, affecting the strength and dimensional accuracy of castings. High-purity lead alloys can reduce the occurrence of these defects. In addition, controlling the uniform distribution of alloying elements can also help reduce internal stress and improve product quality. Material selection and smelting process should pay attention to impurity control.

Material selection for different application requirements

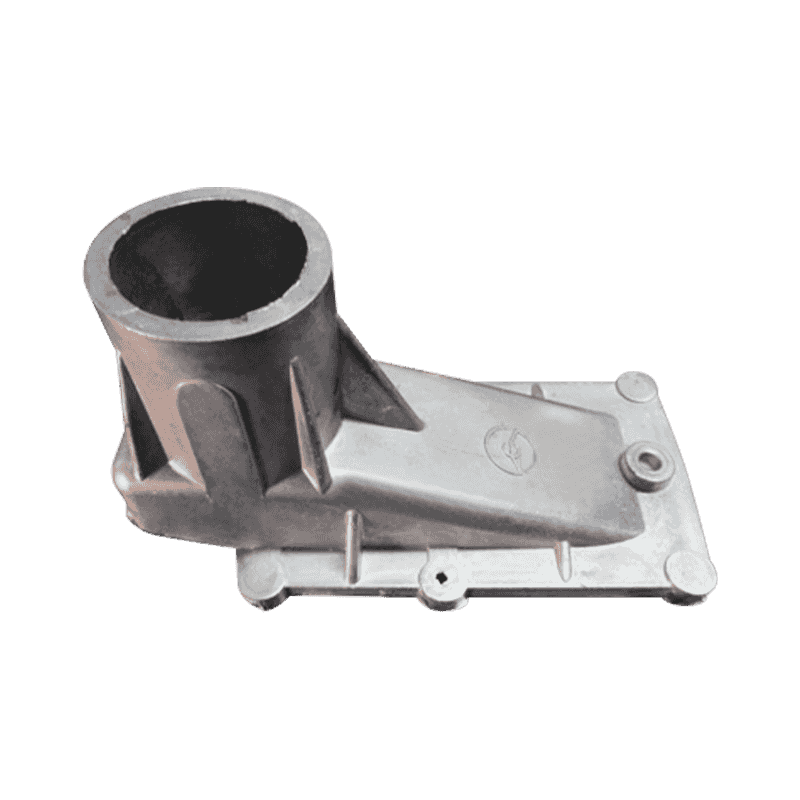

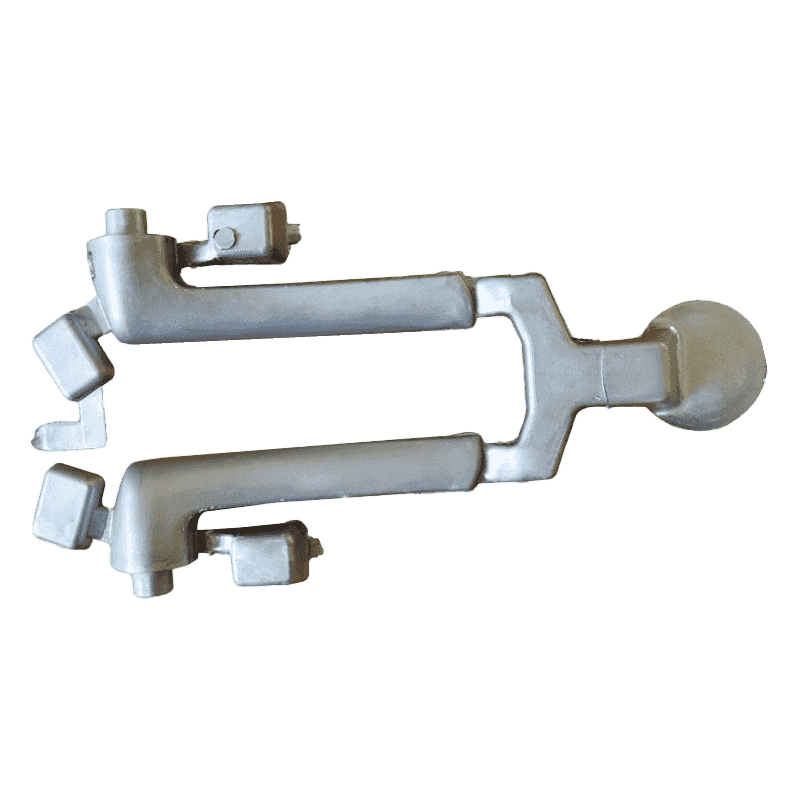

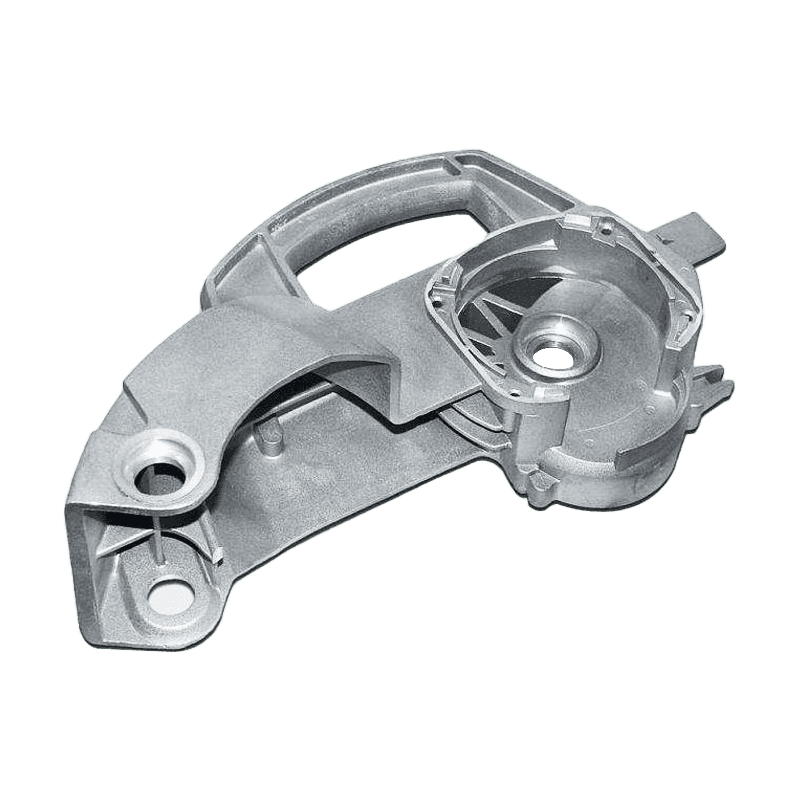

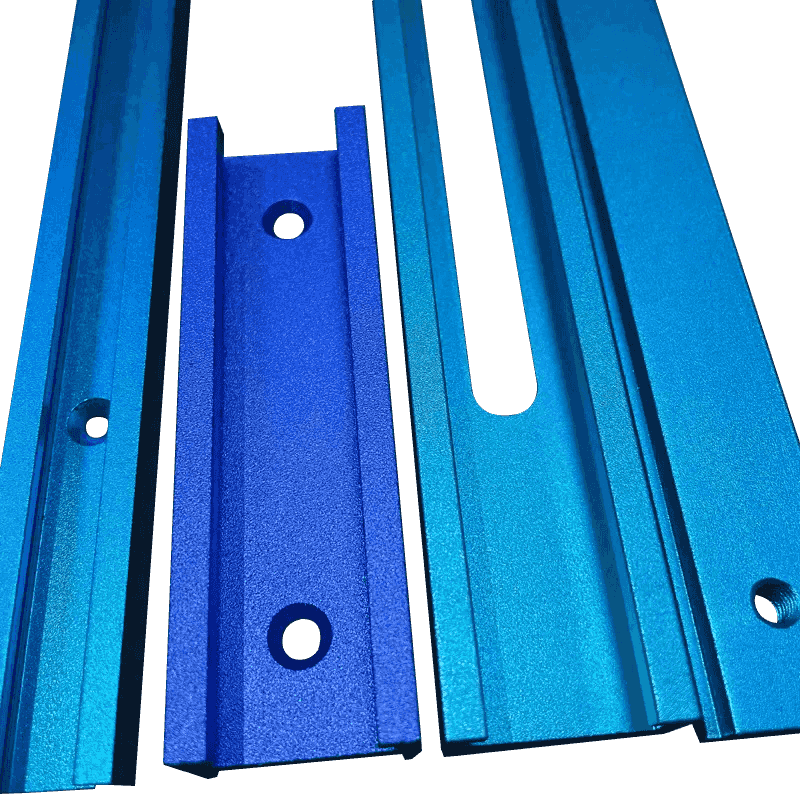

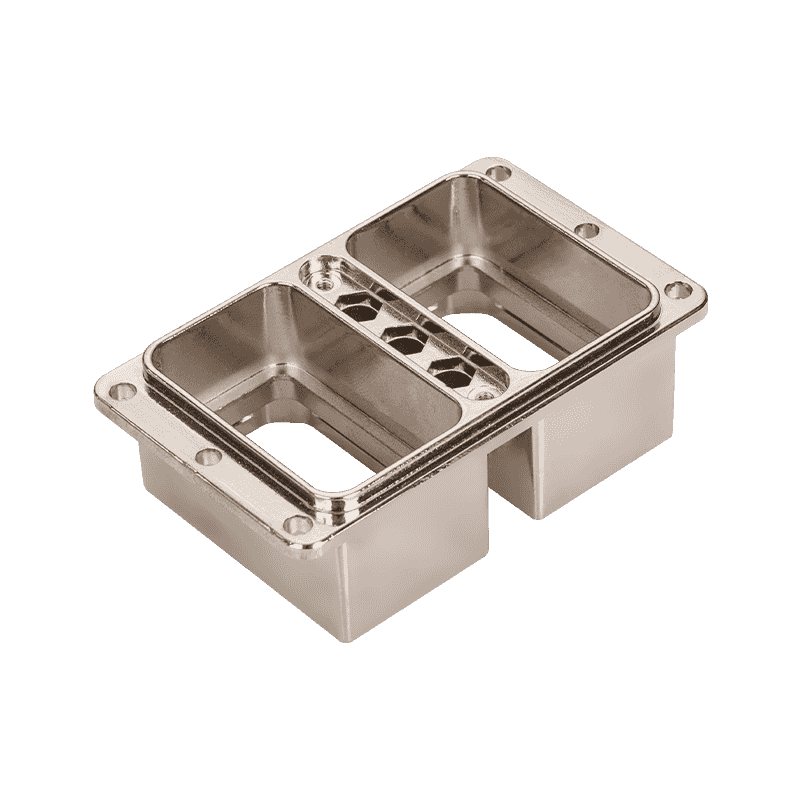

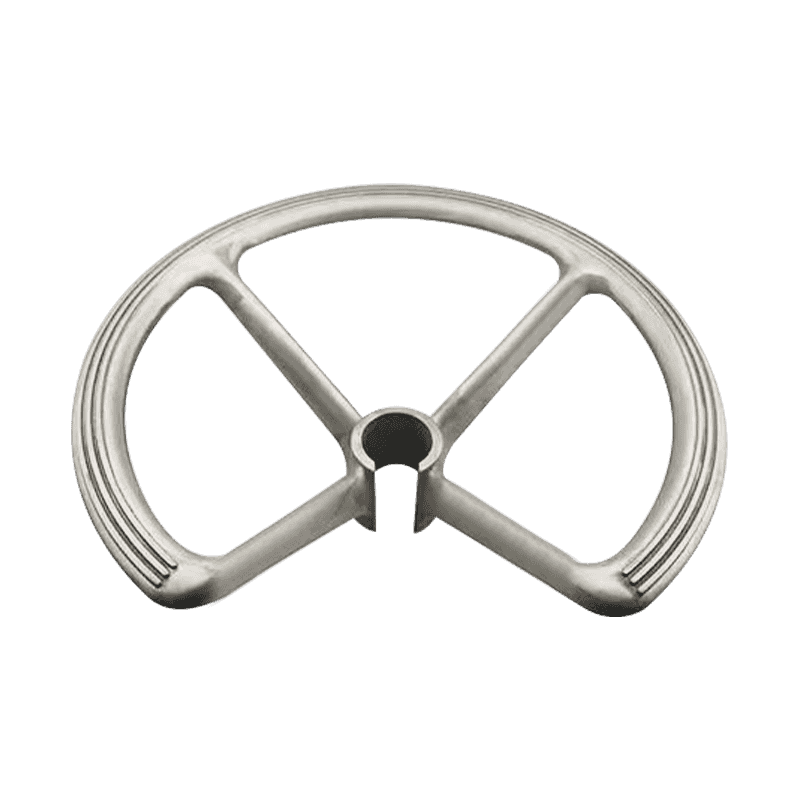

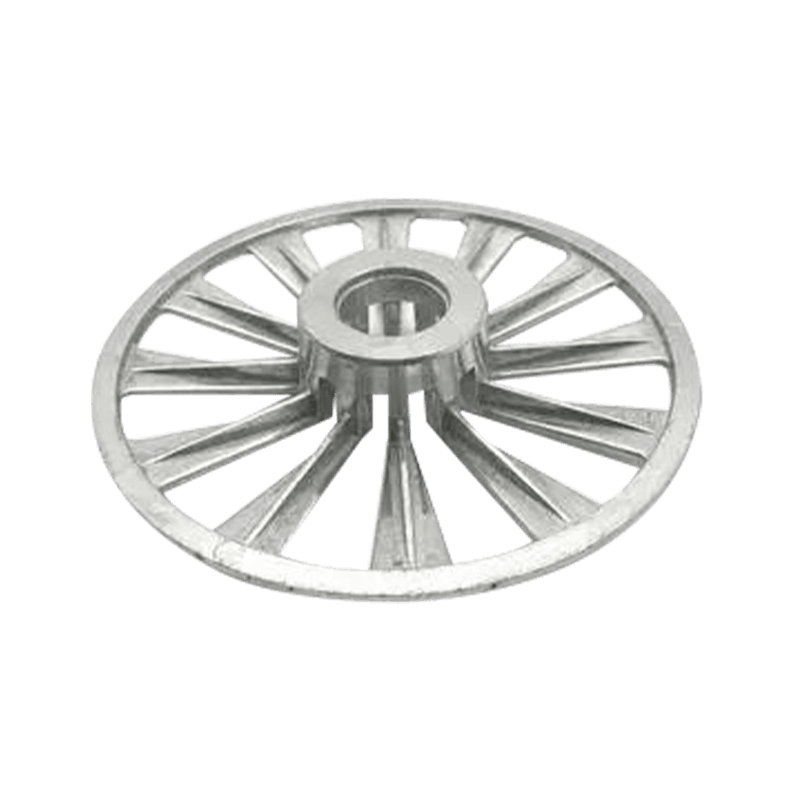

Lead die castings are widely used in mechanical parts, electronic components, protective materials and other fields. The choice of materials varies depending on the specific application environment and performance requirements. For example, for parts that need to withstand greater mechanical stress, alloys with higher antimony content are more suitable; for parts with higher corrosion resistance requirements, it is necessary to consider adjusting the copper content. Reasonable matching of material properties and usage conditions can help extend the life of castings.

Common lead alloy composition and performance comparison table

| Alloy Type | Main Composition (%) | Fluidity | Strength | Hardness | Typical Applications |

|---|---|---|---|---|---|

| Pure Lead | Pb ≥ 99.9 | Good | Low | Low | Simple shapes, low strength requirement parts |

| Lead-Tin Alloy | Pb 85-95, Sn 5-15 | Fair | Medium | Medium | General mechanical parts, electronic housings |

| Lead-Antimony Alloy | Pb 85-90, Sb 5-15 | Average | Higher | Higher | Load-bearing parts, wear-resistant components |

| Lead-Tin-Antimony Alloy | Pb 80-90, Sn 5-10, Sb 5-10 | Average | Higher | Higher | Parts requiring balanced strength and corrosion resistance |

| Lead-Copper Alloy | Pb 85-90, Cu 5-10 | Fair | Medium | Medium | Parts with high corrosion resistance requirements |

Are You Interested In Our Products

Leave your name and email address to get our prices and details immediately.

English

English 中文简体

中文简体 Deutsch

Deutsch русский

русский